EX-M05 40983307 UK.indd RH 15.07.19

Test Unit

Series EX-M05

7

Operation Manual

Parker Hannifin Corporation

Function description

Setting an internal command output

Before a valve is connected to the ValveMaster,

the internal command value should be disabled

to minimize risks. This operating condition is indi-

cated by a flashing command range LED (11) and

the lit CMD Mode button (9) and can be achieved

by turning on the ValveMaster (17) or by pushing

the corresponding button (9).

The deactivation of the internal command

value is equal to the activation of the exter-

nal command reference mode!

If the internal command value is disabled, you can

use the select button (13) to select all available

command ranges sequentially.

The correct command range for the valve

can be found in the operation manual de-

pending on the valve’s product code!

By selecting measuring channel D and pressing

the command button (1)(2) you can preset two

command values via the potentiometers (4)(5).

If you have found the correct command range to

the valve and selected it, you can activate the in-

ternal set point by pressing the CMD Mode but-

ton (9). The background lighting of the CMD Mode

button (9) extinguishes and the command range

LED (11) is lit permanently.

By default, the test unit now returns the value for

the zero position of the valve. In the command

range 4...12...20 mA it is 12 mA, in the command

range -10...0...+10 V it is 0 V and in the command

range 4...20 mA it is 4 mA.

By pressing a corresponding command button (1)

(2), the previously set command value is availa-

ble on Pin D&E of the valve plug. It is still possible

to change both command values via the potenti-

ometers (4)(5). Pressing the CMD Zero button (3)

brings the valve back to zero position.

External command source

The ValveMaster is also able to use command val-

ues from an external source. These external sig-

nals are looped through to the valve and must be

in a range of ±10 V (for voltage) or ±20 mA (for

current).

Pay attention to the current flow direction

by current signals referring to the Pin D&E

(12)!

Before you connect an external source, ensure

that the ValveMaster is in external mode. The ex-

ternal mode is indicated by a lit CMD Mode but-

ton (9) and a flashing command range LED (11).

Now you can connect the external source to sock-

ets D&E (12).

The supplied signal value can’t be shown on the

display (10) because the measurement channel D

is only for the internal command values.

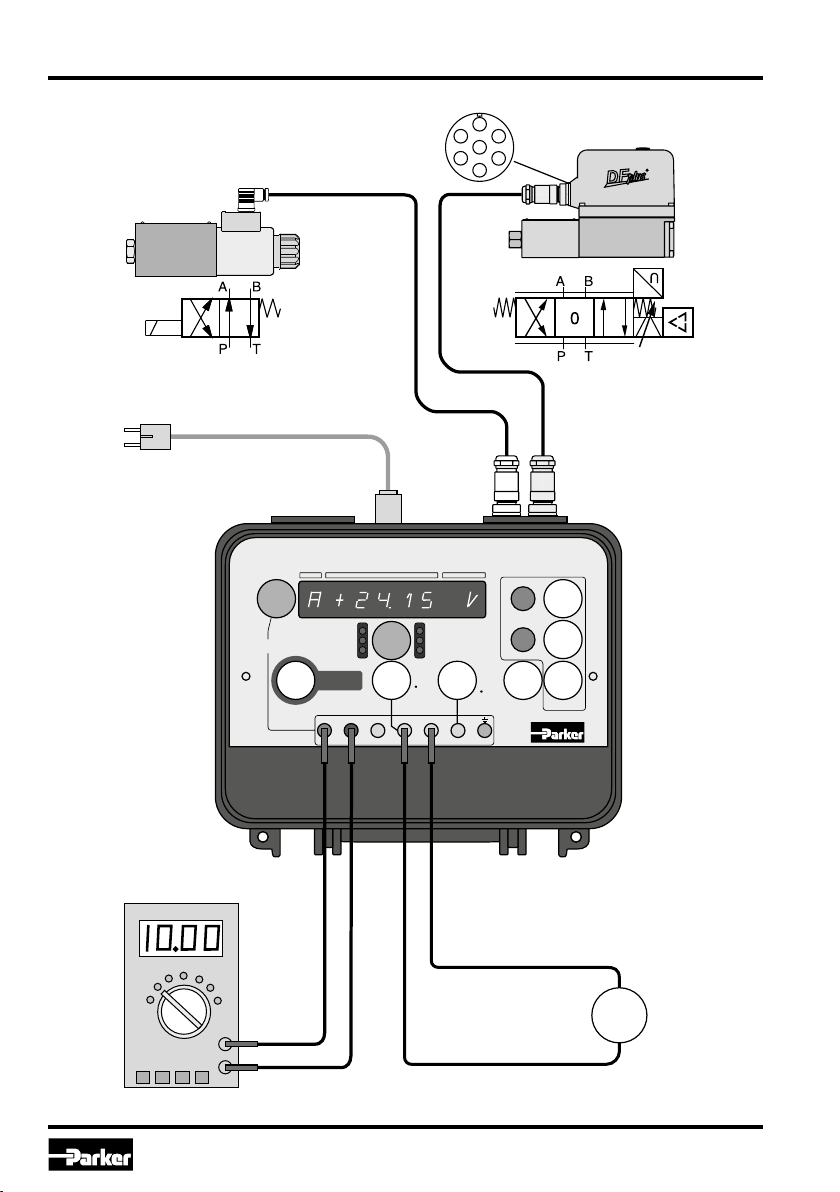

Operation of a DC(On/Off)-valve (max. 40 W)

The DC-valve will be connected via the enclosed

DC-cable to the ValveMaster connector (16). You

can operate the DC-valve by pushing the DC-

valve button (8). The operating status is indicated

by the DC-valve button lighting (8).

DC-valve on: LED on

DC-valve off: LED off

With a power drain greater than 40 W at the Valve

connector (16), the test unit triggers an error and

enters the fault condition mode.