GB/IE/NI 7

Introduction/ Safety instructions

Technical Data

Filter cartridge size: 110 x 90 x 10 mm

Field of vision: 9.2 x 4.2 cm

Bright state: DIN 4

Dark state: DIN 9–DIN 13

Switching times

Bright to dark: 0.23~0.72 ms

Dark to bright: 0.15~0.45 s

Switch on / off: Fully automatic

Energy supply: Solar cell

UV / IR protection: DIN 16

Operating temperature: -5 °C to +55 °C

Storage temperature: -20 °C to + 70 °C

Welding procedure: MMA, MIG, MAG,

TIG, plasma cutting and

plasma welding

Maximum service life: approx. 6 years

Scope of delivery

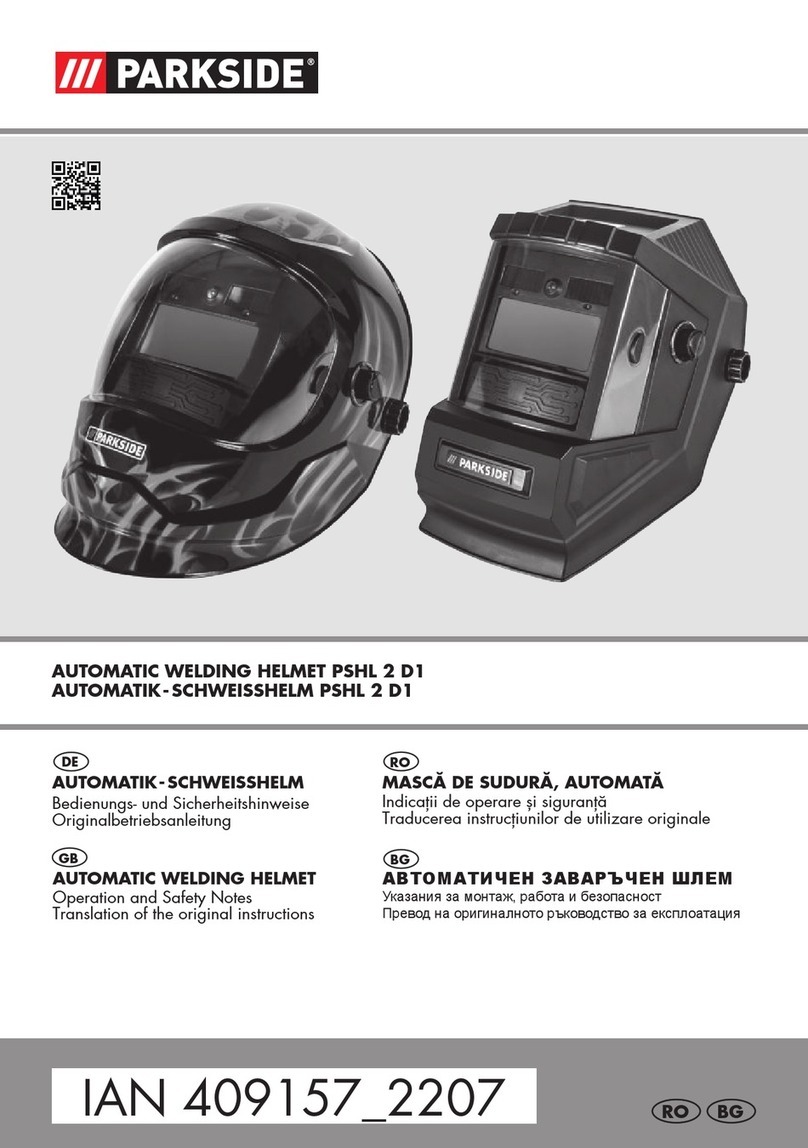

1 Auto-Darkening Welding Helmet

1 Set of instructions for use

Safety instructions

Please carefully read the instructions

for use and follow the specified

notices. Familiarise yourself with the

equipment, its proper use and the

safety notices using these instructions

for use. All technical data about

this welding helmet is on the label,

please learn about this product‘s

technical facts.

This device may be used by

children aged 16 years and up, as

well as by persons with reduced

physical, sensory or mental

capacities, or lacking experience

and / or knowledge, so long as

they are supervised or instructed

in the safe use of the device and

understand the associated risks. Do

not allow children to play with the

product. Cleaning and user main-

tenance should not be performed

by children without supervision.

The welding helmet with auto-

matic darkening is not suitable

for laser and gas welding.

Never place the welding helmet

on hot surfaces.

Never open the welding helmet.

Never carry out repairs on or

modifications to the welding

helmet. These may only be

carried out by trained experts.

Please ensure that you have set

the automatic darkening before

each welding procedure.

The safety visor should not be

opened. It protects the filter from

dirt and damage.

If the filter does not automatically

darken, then immediately end the

welding procedure and contact

the manufacturer.

Only use the welding helmet in

temperatures between -5 °C and

+55 °C. The filter‘s reaction time

will slow down if this tempera-

ture has not been reached or is

exceeded.