8 GB/CY

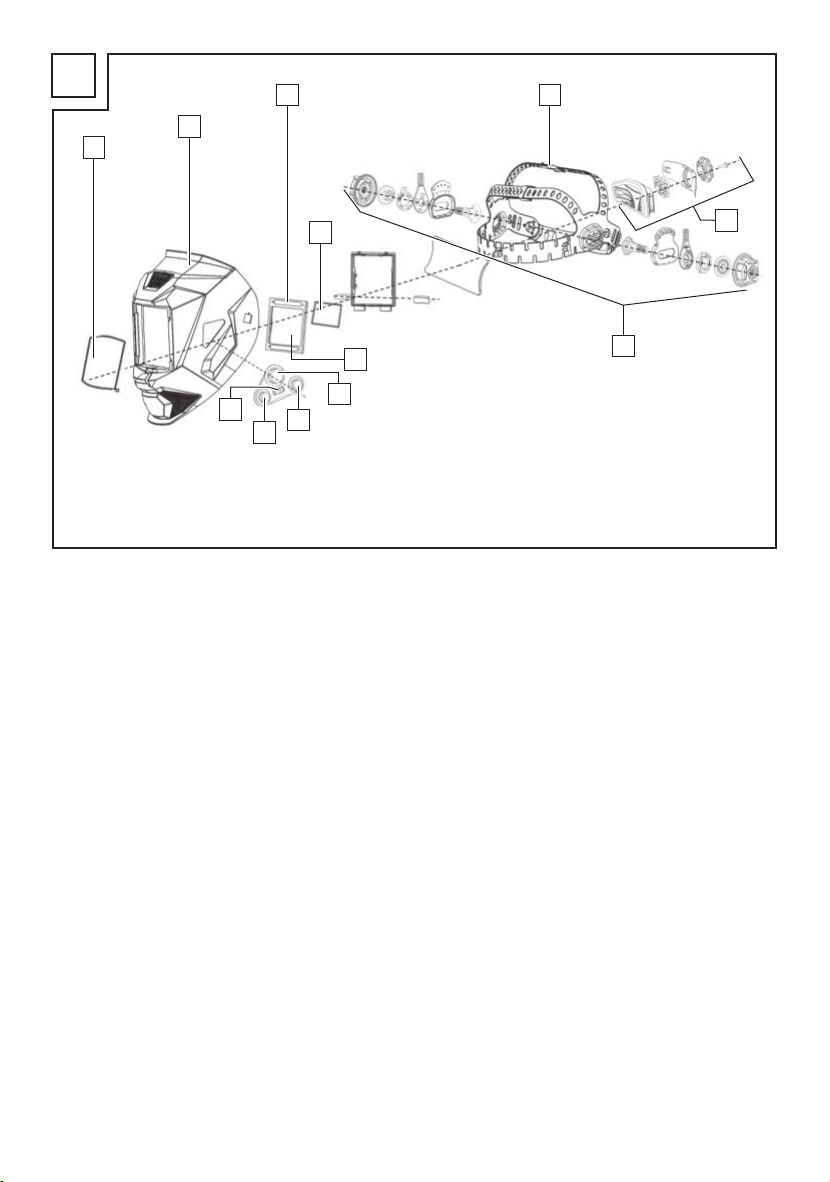

The viewing pane must be

installed on the outer side of

the ADF filter. Otherwise, the

ADF filter can get damaged.

Do not carry out any modifi-

cations/replacements on the

welding helmet and ADF filter

without consent.

If the filter does not darken

automatically whilst welding

please stop the operation

immediately and contact the

dealers without delay.

Do not use any alcohol, fuel

or diluting agents to clean the

ADF filter. Do not place the

ADF filter in water.

The response time of the ADF

liquid crystal slows down if the

ambient temperature is lower,

however this does not have

an impact on the protective

functions.

Please replace the housing

of the ADF filter immediately

if it is damaged or scratched

because this can impair

visibility and the protective

performance.

Please replace the viewing

pane immediately if it is broken

or scratched. Do not use any

hard objects to replace the

viewing pane of the filter.

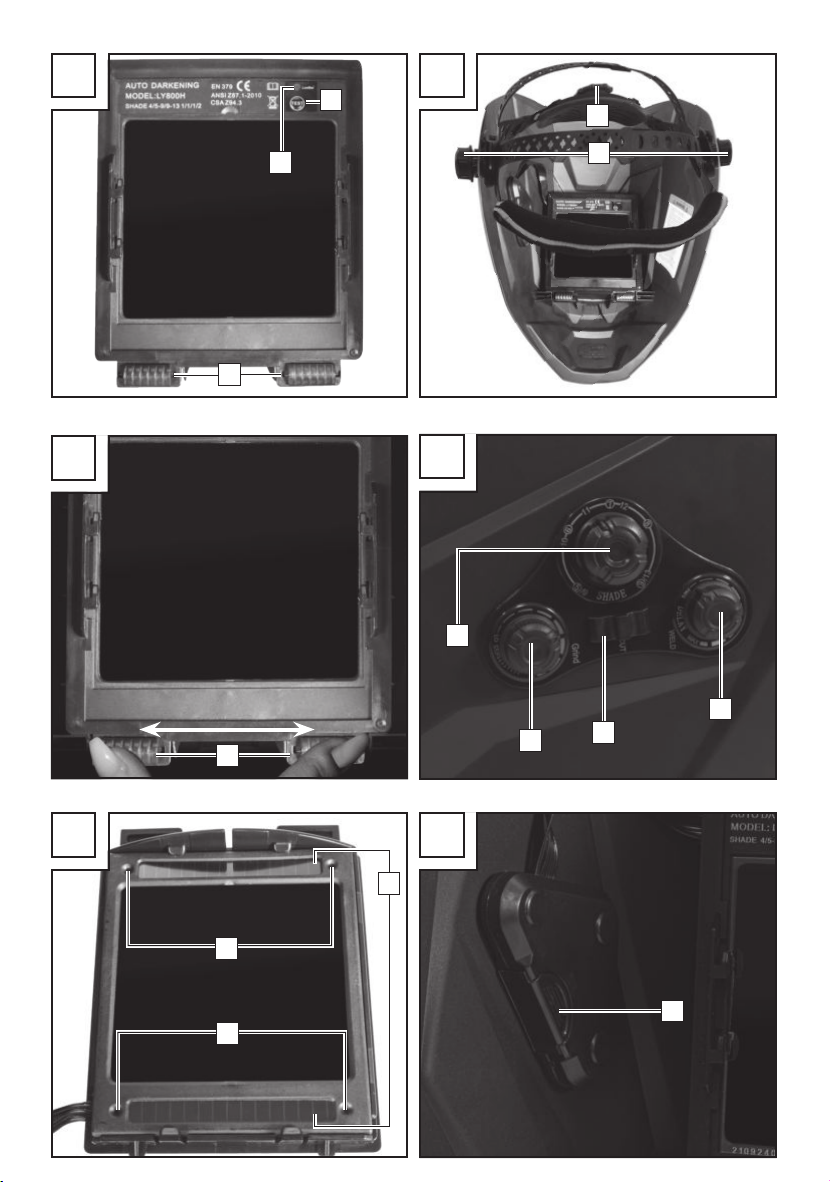

Regularly clean the surfaces of

the ADF filter, sensor and solar

cells.

The welding helmet cannot

withstand any damages that

are caused by a heavy blow,

explosion or abrasive liquids.

The useful life depends on

many different individual

factors such as usage, cleaning,

storage and maintenance.

Regular inspections and

replacement in the case of

damage are recommended.

The material used to manufac-

ture the product will age over

time. This can result in break-

ages on the welding helmet,

for example. As a result of

these damages, the welding

helmet is no longer able to

provide effective protection.

In this case, the user should

replace the welding helmet

immediately.

This product cannot be used

for overhead welding work

and cutting operations. If this

product is used for overhead

welding or cutting, the molten

metal drops could burn

through the ADF filter and

result in injuries to the user.

If the filter is faulty, the user

must stop using the welding

helmet immediately.

Slag splashes can damage the

surface of the filter and cause

injury to the user’s skin or

cause other serious accidents.