1

1. Introduction..............................................................................................2

1.1 Safety Warning ..........................................................................................................2

1.2 Note ...........................................................................................................................2

2. General Information ................................................................................3

2.1 Introduction ................................................................................................................3

2.2 Main Features ............................................................................................................3

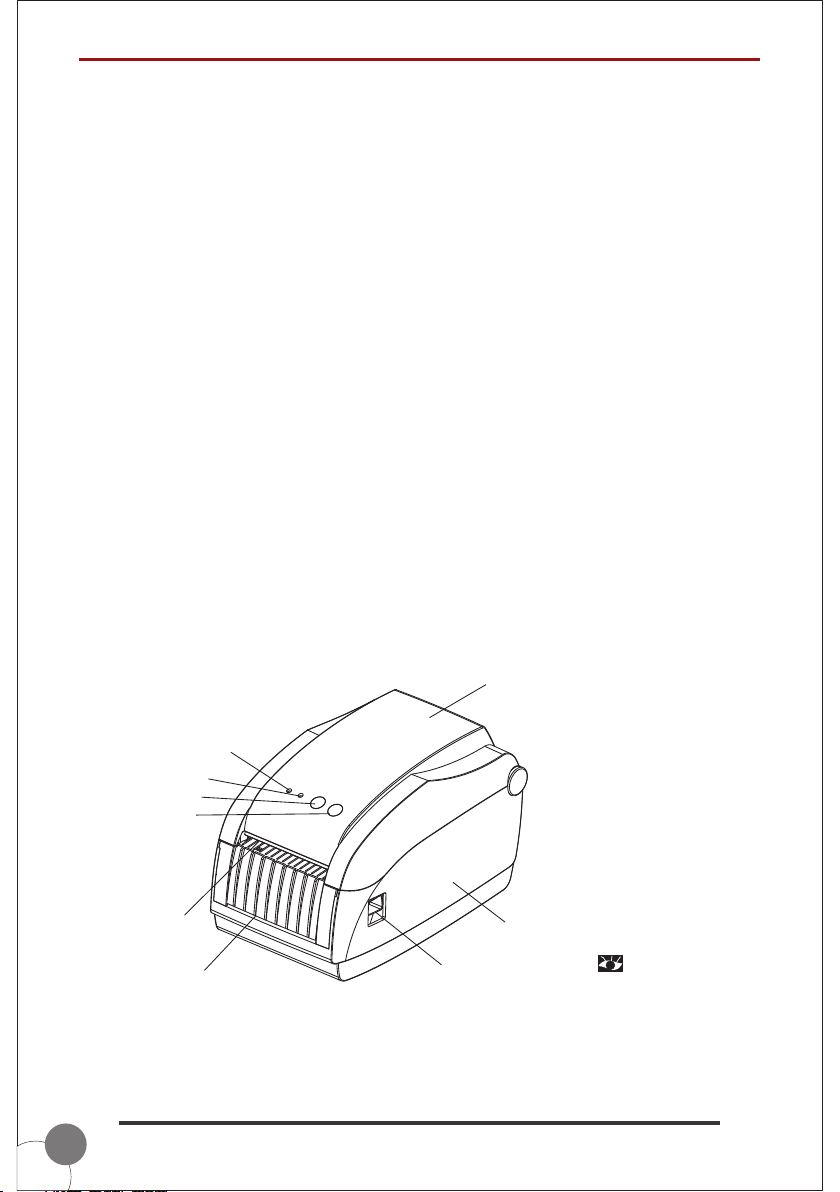

3. Printer Parts ...........................................................................................3

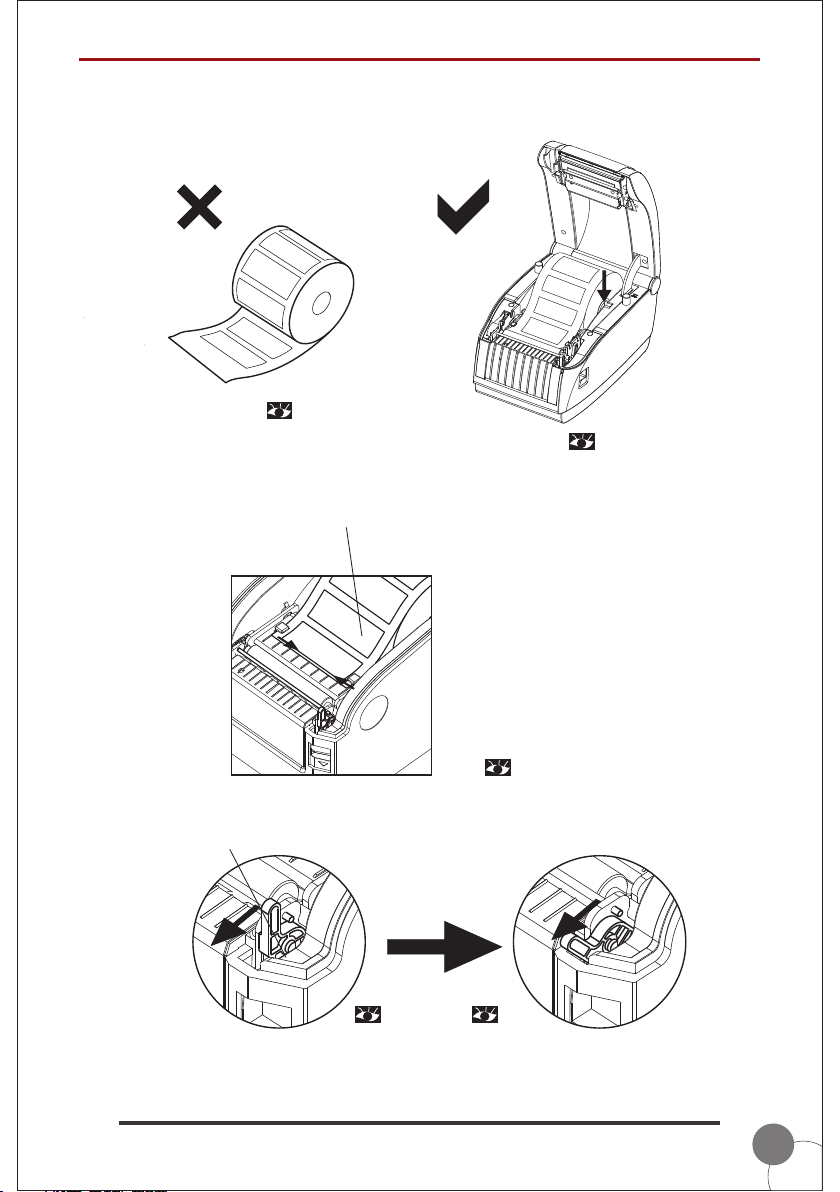

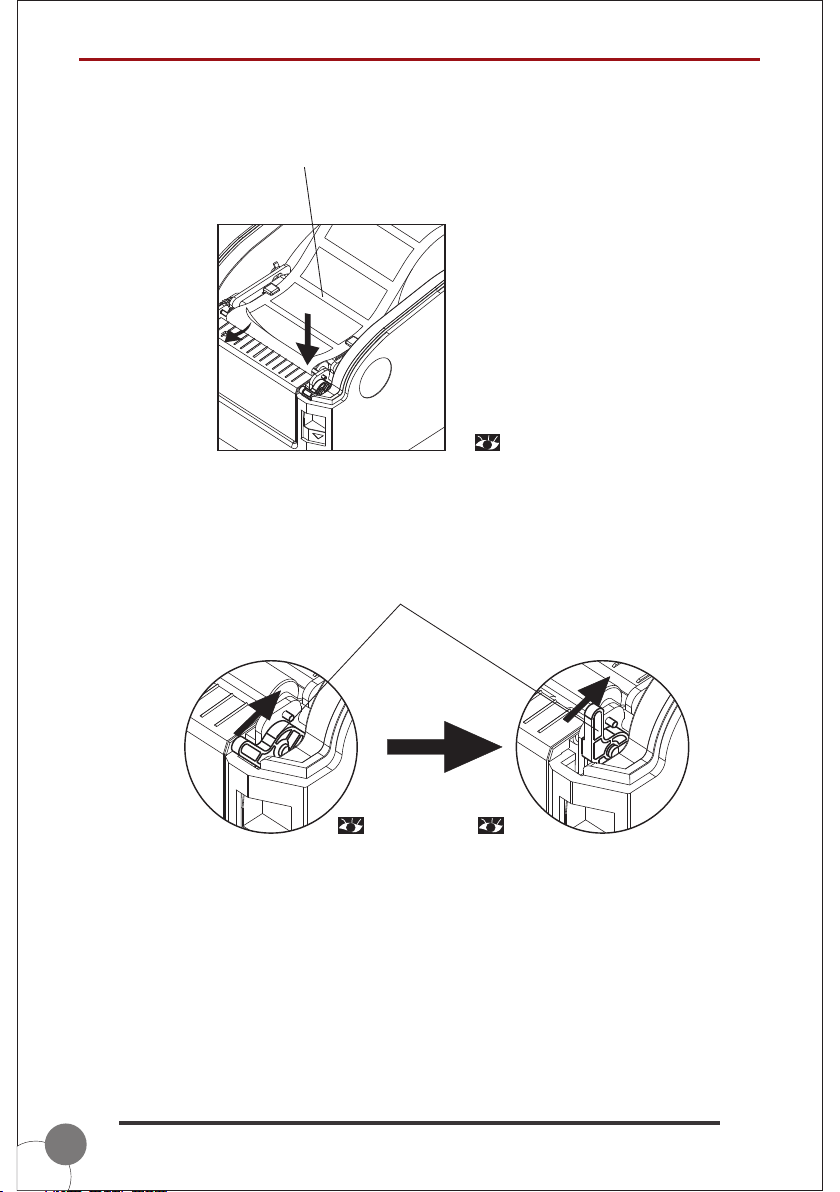

4. Paper Roll Installation ............................................................................5

5. Specification ...........................................................................................8

5.1 Specification Table .....................................................................................................9

6. Setting Up the Printer ...........................................................................10

6.1 Unpacking ................................................................................................................10

6.2 Power Cable Connection .........................................................................................10

6.3 Data Cable Connection ............................................................................................10

6.4 Media Installation .....................................................................................................10

7. Power On Utilities .................................................................................10

7.1 Self-Test ...................................................................................................................10

7.2 Gap Sensor Calibration ...........................................................................................11

7.3 Hexadecimal Dumping .............................................................................................12

7.4 Skip AUTO.BAS .......................................................................................................12

7.5 Printer Initialization ...................................................................................................13

8. Indicators and Buttons..........................................................................13

8.1 Indicators ..................................................................................................................13

8.2 Buttons .....................................................................................................................13

9. Maintenance ..........................................................................................14

9.1 Printer Cleaning .......................................................................................................14

Thermal Barcode Printers

LP-3150TIN Manual