RP-700User’s Manual

Contents

1INTRODUCTION.....................................................................................................................................- 1 -

1.1 OUTLINE ............................................................................................................................................- 1-

1.2 FE AT UR ES ...........................................................................................................................................- 1-

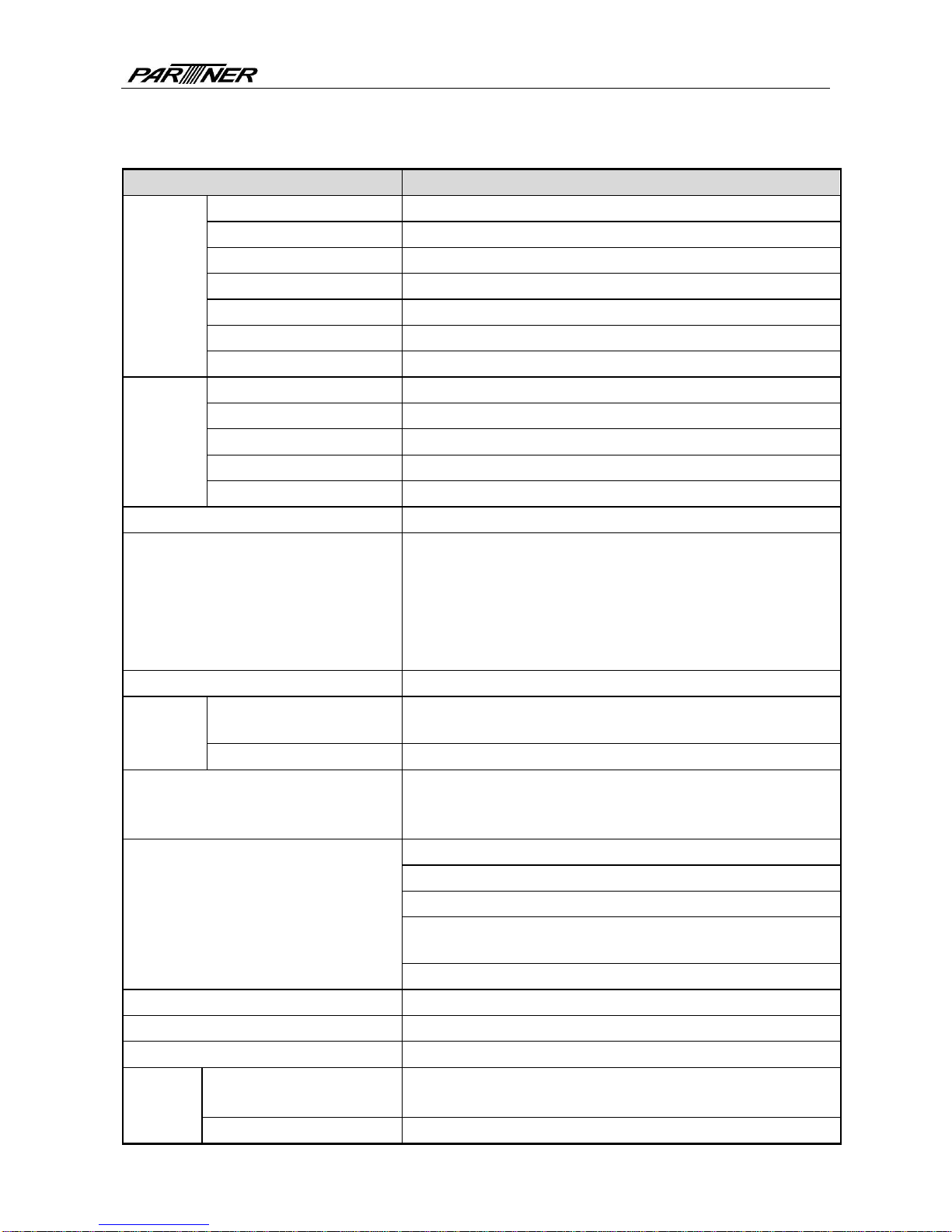

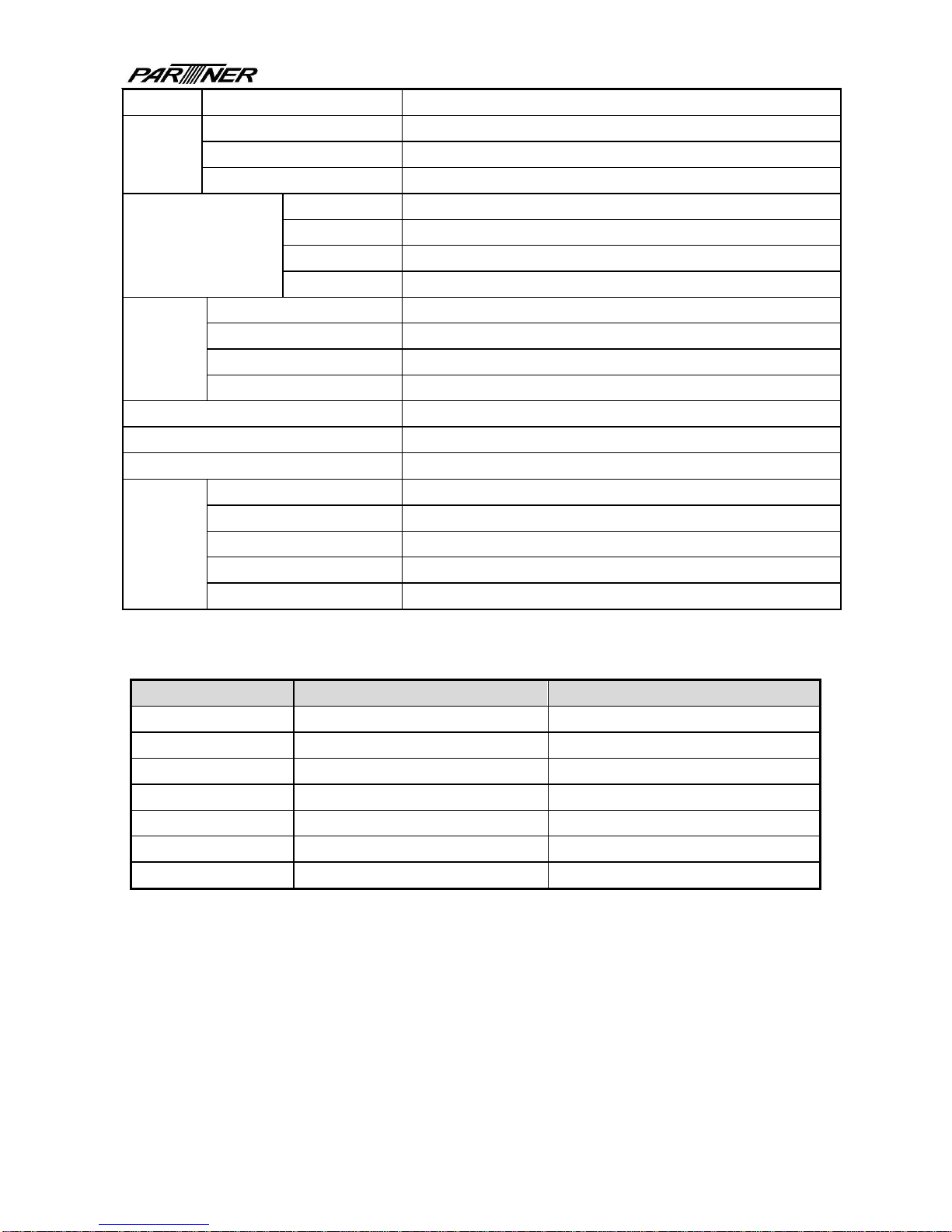

2SPECIFICATION.....................................................................................................................................- 2 -

2.1 TECHNICAL SPECIFICATION .................................................................................................................- 2-

2.2 CUTTER PARAMETERS .........................................................................................................................- 3-

2.3 PAPER SPECIFICATION .........................................................................................................................- 3-

2.3.1 Parameters of continuous paper...............................................................................................- 3 -

2.3.2 Parameters of marked paper.....................................................................................................- 4 -

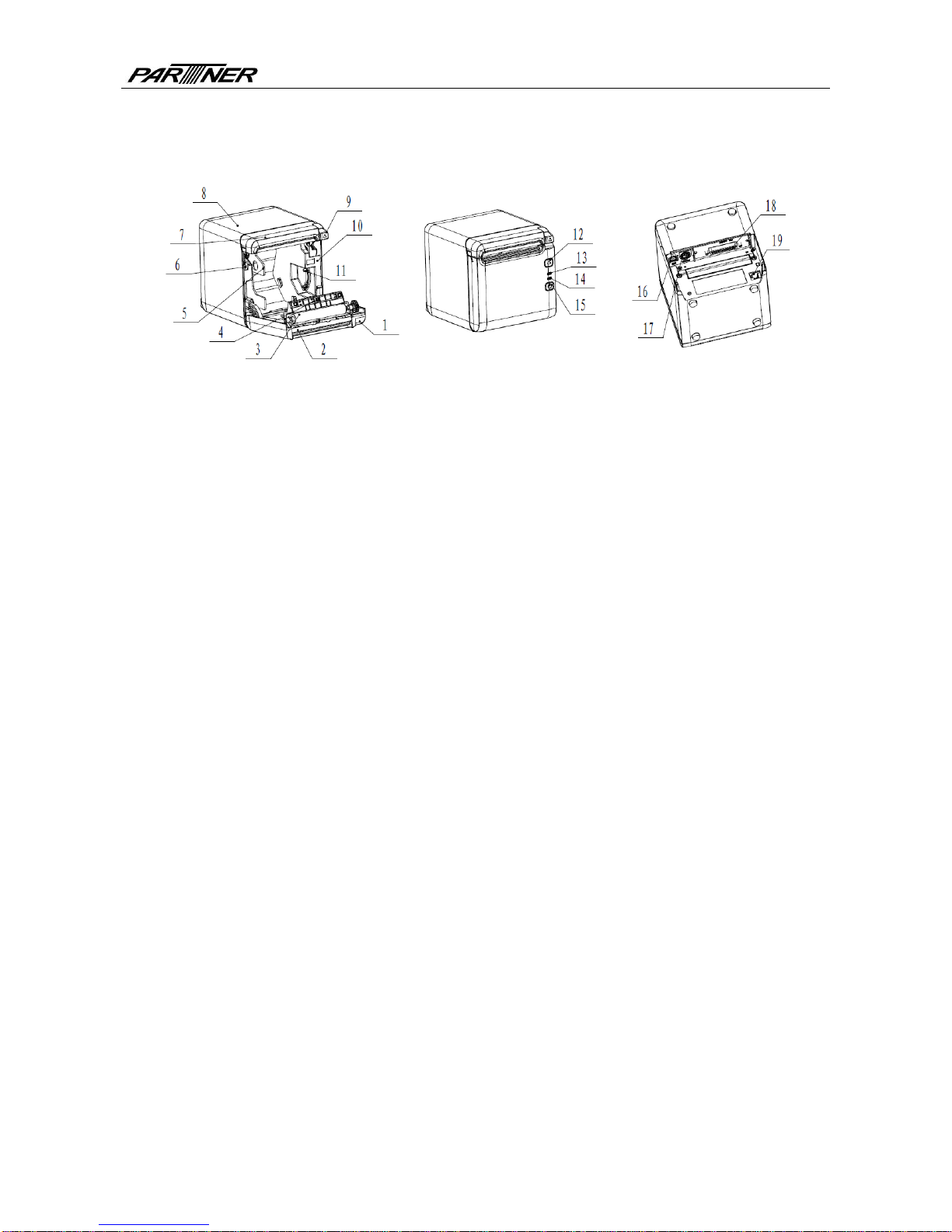

3APPEARANCE AND COMPONENTS...................................................................................................- 5 -

3.1 APPEARANCE AND MODULES...............................................................................................................- 5-

3.2 LED AND BUZZER ...............................................................................................................................- 7-

4INSTALLATION.......................................................................................................................................- 8 -

4.1 UNPACKING ........................................................................................................................................- 8-

4.2 PRINTER INSTALLATION ......................................................................................................................- 8-

4.3 POWER AND COMMUNICATION INTERFACE............................................................................................- 9-

4.3.1 Power connection.......................................................................................................................- 9 -

4.3.2 Interface connection...................................................................................................................- 9 -

4.3.3 USB interface connection........................................................................................................- 10 -

4.3.4 Cash drawer connection..........................................................................................................- 10 -

4.4 PAPER ROLL INSTALLATION ...............................................................................................................- 10 -

4.4.1 Paper type confirmation...........................................................................................................- 10 -

4.4.2 Install/replace paper roll..........................................................................................................- 10 -

4.5 PAPER NEAR END POSITION ADJUSTMENT ...........................................................................................- 12 -

4.6 POWER-ON AND SELF-TEST................................................................................................................- 13 -

4.6.1 Power-on...................................................................................................................................- 13 -

4.6.2 Print self-test page...................................................................................................................- 13 -

4.7 HEXADECIMAL DUMPING FUNCTION ..................................................................................................- 13 -

5ROUTINE MAINTENANCE ..................................................................................................................- 15 -

- 3 -