XR937H - Large View Light Reactive Welding and Grinding HelmetXR937H - Large View Light Reactive Welding and Grinding Helmet

4 5

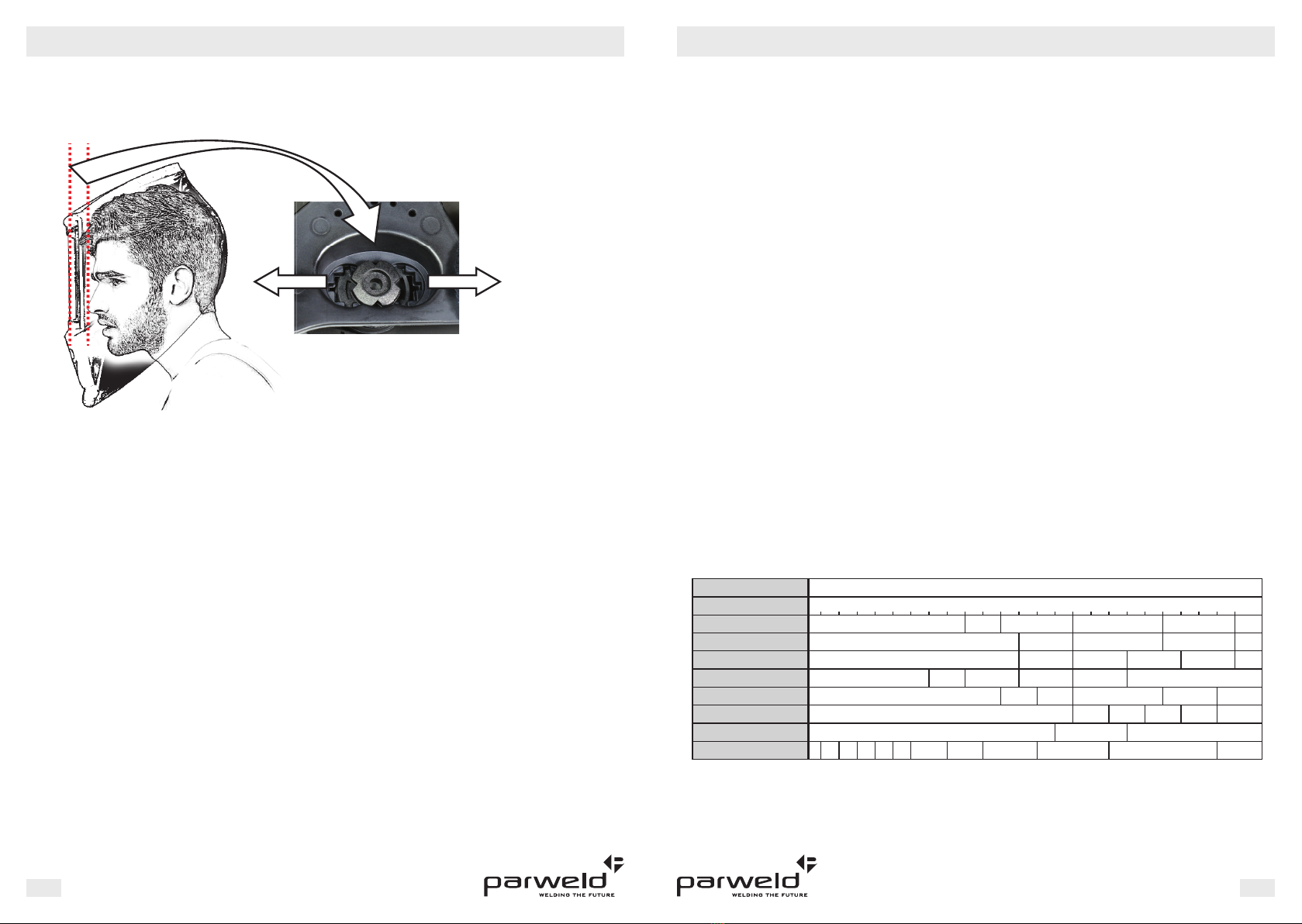

5. Adjustment to Suit Your Head

b. Adjust the Distance Between Face and ADF

MIN

Slacken external adjusting knobs

and then slide forward or back

6. Operating Instructions

• Open the package and take out the

helmet. Check to make sure it is intact and

undamaged including the lithium battery,

installed on the helmet.

• Do not use the Welding Helmet if the lens

is cracked or if the lens is dirty.

• Adjusting the switch sensitivity –the

operator can adjust the amount of

light required for the lens to darken,

depending on working conditions. Reduce

sensitivity to avoid interference from

lighting or other welders nearby. When

working with a low power or TIG welding

high sensitivity is preferred.

• Adjusting dark to clear delay –the time

for the filter to return to clear state can

be adjusted, depending on working

conditions level. When welding is stopped,

the filter screen automatically changes

from dark to clear state according to the

time setting selected. For high amperage

select a long delay or for TIG applications

to prevent flickering at low power.

Short delay is preferred for spot welding

applications.

• Adjusting the Shade Range –the operator

can select (DIN) variable shades from 9 to

13 at the turn of the shade knob. Refer to

Recommended Shade Numbers on page 5

for shade selection.

• This helmet provides protection for arc

welding purposes only. It is not suitable

for laser welding processes. The Welding

Helmet will not protect against severe

impact hazards. The Welding Helmet will

also not protect against explosive devices

or corrosive liquids.

• Use only at temperatures within the

operating range.

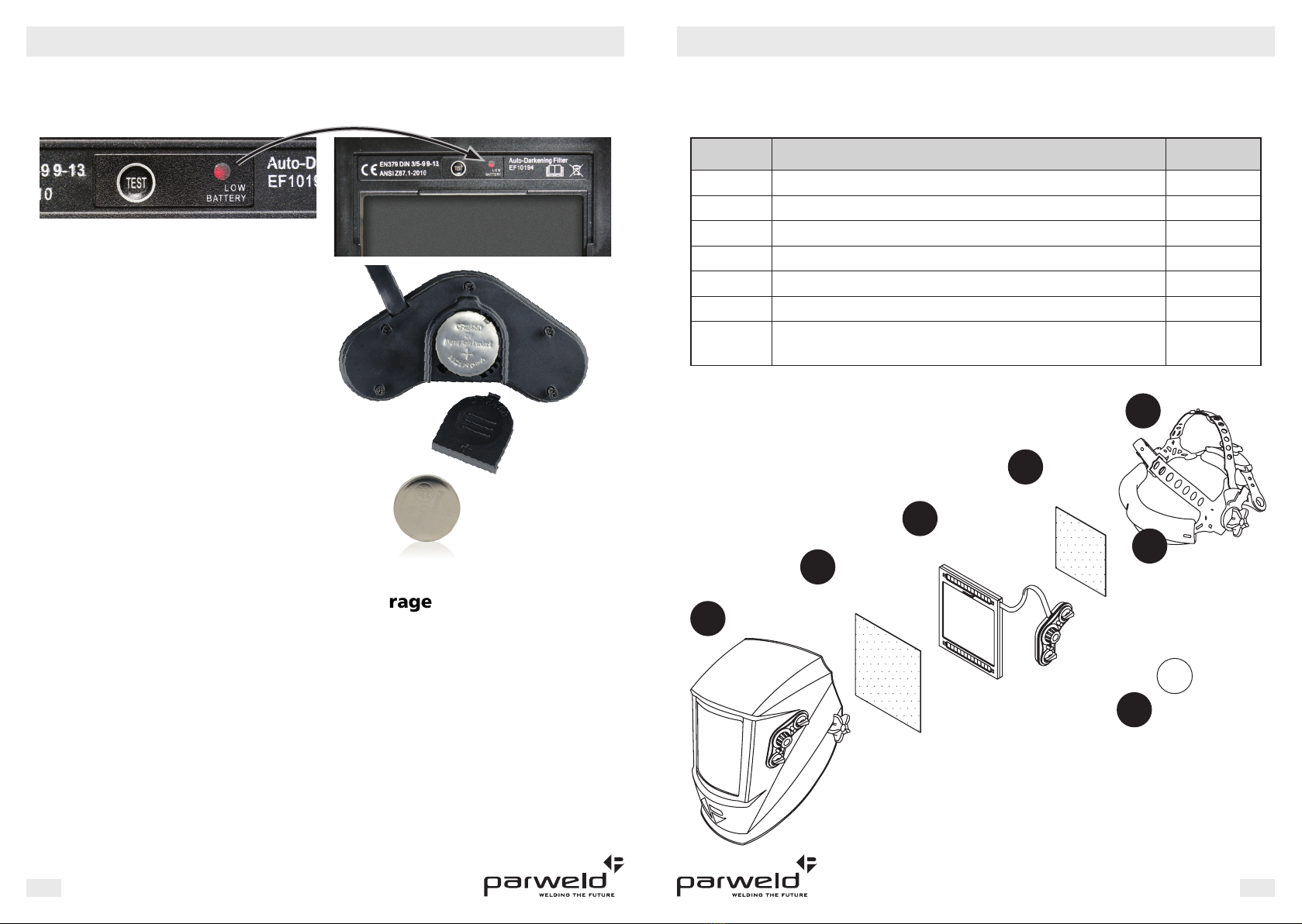

7. Maintenance

To Replace the Cover Lens

• Remove the Front Lens Cover by sliding

the 2 tabs at the base of the filter unit

on the inside of the helmet to the unlock

position.

• Lift up the lower end of the frame and the

ADF unit and slide out the old filter.

• Remove the protection film from both

sides of the new Lens. Place the new Lens

into position.

• Refit the ADF and the locking frame

ensuring the tabs at the top of the frame

are engaged before locking the sliders at

the base.

• Clean the filter lens with a lint-free tissue

or cotton cloth.

• Do not immerse the lens in water or any

other liquid. Do not use abrasives, solvents

or oil based cleaners.

• Do not remove the Auto-Darkening

filter from the Auto-Darkening Welding

Helmet. Do not try to open the filter.

• Clean filter’s surfaces regularly. Protect

filter from contact with any liquid and

dirt. Do not immerse the filter in water.

• Should the Auto-Darkening Welding

Helmet not darken upon striking an arc,

stop welding immediately and check if the

battery needs replacing. If the lens still

does not darken, have the helmet checked

by an authorized service technician.

• Replace the Front Lens Cover if it is

cracked, scratched or damaged in any way.

• The Auto Darkening Filter must never be

placed on a hot surface.

4

10 15 20 30 00257105152155.215.0 005054001080604 225 250 275 300

CURRENT AMPERES

4111edahS019edahS Shade 13Shade 12

350 400

Shade 11

51edahS01edahS 11 12 13 14

14

Shade 10 Shade 11 Shade 12 Shade 13 Shade 14 15

Shade 13Shade 12Shade 10

Shade 14 Shade 15

Shade 9 10 Shade 11 Shade 12

8 9 10 11

Shade 13 Shade 14

Shade 10 11 12 Shade 13

51edahS21edahS Shade 13 Shade 14

Shade 11 Shade 12 Shade 13

567

WELDING PROCESS

Covered Electrodes

MIG Plate Welding

MIG Sheet Welding

TIG

MAG

Arc Gouging

Plasma Cutting

Plasma Welding

Recommended Shade Numbers