PCB TORKDISC 5308D-02A User manual

Model 5308D-02A

TORKDISC® Rotary Torque Sensing System

Installation and Operating Manual

For assistance with the operation of this product,contact:

PCB Load & Torque, Inc.

Toll-free: 866-684-7107

24-hour SensorLine™: 716-684-0001

Fax: 248-888-8266

Web: www.pcbLoadTorque.com

Manual 21354 Rev E

ECN 50523

Repair and Maintenance

PCB guarantees Total Customer Satisfaction through its

“Lifetime Warranty Plus” on all Platinum Stock Products

sold by PCB and through its limited warranties on all other

PCB Stock, Standard and Special products. Due to the

sophisticated nature of our sensors and associated

instrumentation, field servicing and repair is not

recommended and, if attempted, will void the factory

warranty.

Beyond routine calibration and battery replacements

where applicable, our products require no user

maintenance. Clean electrical connectors, housings, and

mounting surfaces with solutions and techniques that will

not harm the material of construction. Observe caution

when using liquids near devices that are not hermetically

sealed. Such devices should only be wiped with a

dampened cloth—never saturated or submerged.

In the event that equipment becomes damaged or ceases

to operate, our Application Engineers are here to support

your troubleshooting efforts 24 hours a day, 7 days a

week. Call or email with model and serial number as well

as a brief description of the problem.

Calibration

Routine calibration of sensors and associated

instrumentation is necessary to maintain measurement

accuracy. We recommend calibrating on an annual basis,

after exposure to any extreme environmental influence,

or prior to any critical test.

PCB Piezotronics is an ISO-9001 certified company whose

calibration services are accredited by A2LA to ISO/IEC

17025, with full traceability to SI through N.I.S.T. In

addition to our standard calibration services, we also offer

specialized tests, including: sensitivity at elevated or

cryogenic temperatures, phase response, extended high

or low frequency response, extended range, leak testing,

hydrostatic pressure testing, and others. For more

information, contact your local PCB Piezotronics

distributor, sales representative, or factory customer

service representative.

Returning Equipment

If factory repair is required, our representatives will

provide you with a Return Material Authorization (RMA)

number, which we use to reference any information you

have already provided and expedite the repair process.

This number should be clearly marked on the outside of

all returned package(s) and on any packing list(s)

accompanying the shipment.

Contact Information

PCB Piezotronics, Inc.

3425 Walden Ave.

Depew, NY14043 USA

Toll-free: (800) 828-8840

24-hour SensorLine: (716) 684-0001

Repair inquiries: rma@pcb.com

For a complete list of distributors, global offices and sales

representatives, visit our website, www.pcb.com.

Safety Considerations

This product is intended for use by qualified personnel

who recognize shock hazards and are familiar with the

precautions required to avoid injury. While our equipment

is designed with user safety in mind, the protection

provided by the equipment may be impaired if equipment

is used in a manner not specified by this manual.

Discontinue use and contact our 24-Hour Sensorline if:

Assistance is needed to safely operate equipment

Damage is visible or suspected

Equipment fails or malfunctions

For complete equipment ratings, refer to the enclosed

specification sheet for your product.

Definition of Terms and Symbols

The following symbols may be used in this manual:

DANGER

Indicates an immediate hazardous

situation, which, if not avoided, may

result in death or serious injury.

Manual 21354 Rev E

ECN 50523

CAUTION

Refers to hazards that could damage

the instrument.

NOTE

Indicates tips, recommendations and

important information. The notes

simplify processes and contain

additional information on particular

operating steps.

The following symbols may be found on the equipment

described in this manual:

This symbol on the unit indicates that

high voltage may be present. Use

standard safety precautions to avoid

personal contact with this voltage.

This symbol on the unit indicates that

the user should refer to the operating

instructions located in the manual.

This symbol indicates safety, earth

ground.

Manual 21354 Rev E

ECN 50523

PCB工业监视和测量设备 - 中国RoHS2公布表

PCB Industrial Monitoring and Measuring Equipment - China RoHS 2 Disclosure Table

部件名称

有害物质

铅(Pb)

汞

(Hg)

镉

(Cd)

六价铬(Cr(VI))

多溴联苯 (PBB)

多溴二苯醚(PBDE)

住房

O

O

O

O

O

O

PCB板

X

O

O

O

O

O

电气连接器

O

O

O

O

O

O

压电晶体

X

O

O

O

O

O

环氧

O

O

O

O

O

O

铁氟龙

O

O

O

O

O

O

电子

O

O

O

O

O

O

厚膜基板

O

O

X

O

O

O

电线

O

O

O

O

O

O

电缆

X

O

O

O

O

O

塑料

O

O

O

O

O

O

焊接

X

O

O

O

O

O

铜合金/黄铜

X

O

O

O

O

O

本表格依据 SJ/T 11364 的规定编制。

O:表示该有害物质在该部件所有均质材料中的含量均在 GB/T 26572 规定的限量要求以下。

X:表示该有害物质至少在该部件的某一均质材料中的含量超出 GB/T 26572 规定的限量要求。

铅是欧洲RoHS指令2011/65/ EU附件三和附件四目前由于允许的豁免。

CHINA RoHS COMPLIANCE

Manual 21354 Rev E

ECN 50523

Component Name

Hazardous Substances

Lead (Pb)

Mercury (Hg)

Cadmium (Cd)

Chromium VI

Compounds

(Cr(VI))

Polybrominated

Biphenyls (PBB)

Polybrominated

Diphenyl Ethers

(PBDE)

Housing

O

O

O

O

O

O

PCB Board

X

O

O

O

O

O

Electrical Connectors

O

O

O

O

O

O

Piezoelectric Crystals

X

O

O

O

O

O

Epoxy

O

O

O

O

O

O

Teflon

O

O

O

O

O

O

Electronics

O

O

O

O

O

O

Thick Film Substrate

O

O

X

O

O

O

Wires

O

O

O

O

O

O

Cables

X

O

O

O

O

O

Plastic

O

O

O

O

O

O

Solder

X

O

O

O

O

O

Copper Alloy/Brass

X

O

O

O

O

O

This table is prepared in accordance with the provisions of SJ/T 11364.

O: Indicates that said hazardous substance contained in all of the homogeneous materials for this part is below the limit

requirement of GB/T 26572.

X: Indicates that said hazardous substance contained in at least one of the homogeneous materials for this part is above the limit

requirement of GB/T 26572.

Lead is present due to allowed exemption in Annex III or Annex IV of the European RoHS Directive 2011/65/EU.

PCB Load & Torque Toll-Free in USA 866-684-7107 716-684-0001 www.pcb.com

16-BIT TORKDISCROTARY TORQUE SENSOR SYSTEM OPERATION MANUAL

1

TABLE OF CONTENTS

GENERAL GUIDELINES...........................................................................................................2

WARNING SYMBOLS AND TERMS.........................................................................................2

1.0 INTRODUCTION..................................................................................................................3

2.0 SAFETY PRECAUTIONS....................................................................................................3

3.0 OVERVIEW..........................................................................................................................3

3.1 Supplied Components.......................................................................................................................3

3.2 Dimensions .......................................................................................................................................3

3.3 Theory of Operation..........................................................................................................................5

4.0 ELECTRICAL OPERATION ................................................................................................6

4.1 Receiver Box – Front Panel..............................................................................................................6

4.2 Receiver Box – Back Panel ..............................................................................................................6

4.3 Receiver Box – I/O Connector Pinouts .............................................................................................7

4.4 Receiver Box – Adjustment Controls................................................................................................8

4.4.1 System Gain Range.................................................................................................................9

4.4.2 Zero/Additional Offset..........................................................................................................10

4.4.3 AC Gain................................................................................................................................10

4.4.4 Low & High Pass Filters.......................................................................................................11

4.4.4.1 Low Pass Filter.......................................................................................11

4.4.4.2 Composite Low Pass Filter.....................................................................12

4.4.4.3 Composite High Pass Filter ....................................................................13

5.0 MECHANICAL INSTALLATION........................................................................................14

5.1 TORKDISC

Installation................................................................................................................14

5.2 Mating Adaptors..............................................................................................................................16

6.0 SYSTEM OPERATION ......................................................................................................17

6.1 System Tuning................................................................................................................................17

7.0 CALIBRATION...................................................................................................................17

7.1 Analog Output – Voltage.................................................................................................................18

7.2 Frequency Output ...........................................................................................................................18

8.0 TROUBLESHOOTING.......................................................................................................19

9.0 CALIBRATION / REPAIR SERVICES...............................................................................20

9.1 RMA / Purchase Order....................................................................................................................20

10.0 WARRANTY ....................................................................................................................20

PCB Load & Torque Toll-Free in USA 866-684-7107 716-684-0001 www.pcb.com

16-BIT TORKDISCROTARY TORQUE SENSOR SYSTEM OPERATION MANUAL

2

GENERAL GUIDELINES

Operators should read this manual and become thoroughly familiar with its contents before attempting to

operate the 16-bit TORKDISCrotary torque sensor system. Following the safety considerations and

operation instructions outlined in this manual will minimize the possibility of accidents or injury. Although the

procedures covered in this manual have proven safe in use, PCB Load & Torque assumes no responsibility for

personal injury or damage to equipment resulting from their application. After reading this manual, personnel

should review all instructions concerning safety procedures provided at the installation location. It is not

possible to cover all safety considerations in this manual; therefore, always be alert and work safely. Only

qualified system operators should perform the procedures covered in this manual.

WARNING SYMBOLS AND TERMS

This symbol on the unit indicates that the user should refer to the operating instructions located

in the manual.

This symbol on the unit indicates that high voltage may be present. Use standard safety

precautions to avoid personal contact with this voltage.

This system indicates safety, earth ground.

Indicates a potentially dangerous situation, which can lead to minor or moderate injury or property damage. It may

also be used to alert against unsafe practices.

CAUTION

Indicates a potentially dangerous situation, which can lead to severe personal injury or death. Always read the

associated information very carefully before performing the indicated procedure.

WARNING

Indicates an imminently dangerous situation, which can lead to severe personal injury or death.

DANGER

PCB Load & Torque Toll-Free in USA 866-684-7107 716-684-0001 www.pcb.com

16-BIT TORKDISCROTARY TORQUE SENSOR SYSTEM OPERATION MANUAL

3

1.0 INTRODUCTION

The TORKDISCis ideally designed to measure in-line rotating

shaft torque and incorporates a unique digital telemetry system to

transmit sensor excitation and output between the rotor and stator

portion of the system,

This manual provides instructions for installation, calibration,

operation, and troubleshooting.

2.0 SAFETY PRECAUTIONS

3.0 OVERVIEW

The TORKDISCproduct is a DC powered instrument and includes an external AC/DC power supply. The

transmitter potted into the disc is inductively powered so it does not require any batteries or maintenance. This

manual covers three series of TORKDISCranging in full-scale capacities from 500 to 100k in-lbf.

3.1 Supplied Components

The TORKDISCrotary torque sensor system comes supplied with the following equipment:

•TORKDISCrotor and stator/antenna assemblies.

•Receiver box with DB25 female connector w/mating connector

•Power supply with power cord

•24 foot long BNC plug to TNC plug cable

3.2 Dimensions

This section gives some general dimensions for common TORKDISCassembly models. Reference the

individual model’s outline drawing for extra details or special versions.

Figure 1 – TORKDISCLoading &

Components

Personal injury to the operator, as well as, damage to the equipment may result if the TORKDISCis operated at

speeds higher than the maximum rated speed, or with loads greater than the overload capacity listed on the

specification sheet. The operator should be protected from rotating parts by using safety shield guards. When in

doubt about speed ratings or torque capacity, consult the Load & Torque Division of PCB Piezotronics.

CAUTION

Stator/Antenna

Rotor

CW +

PCB Load & Torque Toll-Free in USA 866-684-7107 716-684-0001 www.pcb.com

16-BIT TORKDISCROTARY TORQUE SENSOR SYSTEM OPERATION MANUAL

4

NOTE: See the outline drawing for the respective series for additional dimensions and bolt circle details.

Figure 2 - Dimensions

Table 1

-

Dimension Values

Dimensions

(see Figure 2)

Series Number

5302

5308

5302

500 – 5k in-lbf 2.4k – 30k in-lbf 50k – 100k in-lbf

(in) (mm) (in) (mm) (in) (mm)

1

9.00 228.6 10.50 266.7 12.45 316.3

2

10.92 277.5 12.28 311.9 14.20 360.6

3 ∅5.99 ∅152.0 ∅7.49 ∅190.1 ∅9.49 ∅240.9

4

7.00 177.8 7.00 177.8 7.00 177.8

5

2.49 63.2 2.49 63.2 2.49 63.2

6

6.12 155.4 6.12 155.4 6.12 155.4

7

7.02 178.2 7.62 193.4 8.58 217.8

8

1.28 32.5 1.28 32.5 1.28 32.5

9

1.55 39.4 1.55 39.4 1.55 39.4

10

0.31 7.9 0.31 7.9 0.31 7.9

11

R0.17 R4.2 R0.17 R4.2 R0.17 R4.2

12 8X ∅0.406

THRU ON

∅5.000

8X ∅10.31

THRU ON

∅127.00

8X ∅0.531

THRU ON

∅6.500

8X

∅13.49THRU

ON ∅165.10

16X ∅0.531

THRU ON

∅8.500

16X ∅13.49

THRU ON

∅215.90

13 8X 3/8”-24

THRU ON

∅3.000

8X 3/8”-24

THRU ON

∅76.25

8X 5/8”-11

THRU ON

∅3.750

8X 5/8”-11

THRU ON

∅95.25

12X 5/8”-11

THRU ON

∅6.000

12X 5/8”-11

THRU ON

∅152.40

14 22.5°22.5°22.5°22.5°22.5°22.5°

15 22.5°

22.5°

28°

28°

25°*

25°*

*20°between holes

4

1

11

9

3

2

6

10

15

15

14

8

5

7

13

12

PCB Load & Torque Toll-Free in USA 866-684-7107 716-684-0001 www.pcb.com

16-BIT TORKDISCROTARY TORQUE SENSOR SYSTEM OPERATION MANUAL

5

3.3 Theory of Operation

The TORKDISCsystem utilizes a unique digital data transmission technique. A radio frequency signal

generated within the receiver box is inductively coupled from the pick-up antenna to the transmitting antenna

and rectified to provide DC voltages to operate the rotating TORKDISCtransmitter. The transmitter has been

configured for a full-scale input of ±1.5mV/V. The rotating circuitry provides excitation for the strain gage

bridge, amplifies, and filters its output. The resulting signal is presented to an analog to digital converter that

samples it and converts it to a noise immune digital code. To provide up to a 8.5kHz measurement bandwidth

without creating aliasing errors, the A-to-D converter samples at a rate in excess of 26,000 samples per second.

Data bits are transmitted off the rotor in this digitally encoded form. In this manner, they are not subject to

noise degradation or "per rev" effects.

The digital data bits are recovered in the receiver box where they are re-converted to an analog signal. This

signal is used to generate the standard voltage output, consult the factory for optional frequency system outputs.

The specified bandwidth represents the electronic capability of the TORKDISCSystem only and does not

reflect actual installed system performance and the influence of sensor and system mechanics. It is advisable

that the customer model the entire drive line with the sensor installed and /or conduct an in-situ torsional

vibration analysis to determine the measurement bandwidth.

The calibration of the TORKDISCsystem is easy to accomplish and is extremely stable over time. The

product is equipped with a remotely activated shunt calibration feature that can be controlled from the front

panel of the receiver box. This allows the user to check calibration at any time during system operation. When

the shunt calibration feature is invoked, a precision resistor is switched across one leg of the Wheatstone bridge,

producing a positive shift in the receiver’s output.

PCB Load & Torque Toll-Free in USA 866-684-7107 716-684-0001 www.pcb.com

16-BIT TORKDISCROTARY TORQUE SENSOR SYSTEM OPERATION MANUAL

6

4.0 ELECTRICAL OPERATION

The receiver box is a signal conditioner and amplifier for the outputs coming from the TORKDISC. It is the

interface between the TORKDISCand the output meter or transient recorder.

4.1 Receiver Box – Front Panel

The front panel of the receiver box contains push-

button switches and LED indicators as shown in

Figure 3.

The front panel switches and LED indicators are

described in Table 2.

POWER:

Press the POWER button to turn the Receiver Box on and off. The amber LED will illuminate when

the internal circuitry has correct power for operation.

TRANSMITTER

LOW POWER:

This red LED is illuminated when the transmitter does not have adequate power to operate the

electronics.

DATA:

This green LED is illuminated when the receiver has received valid data from the transmitter.

SHUNT

CALIBRATION:

This green LED is illuminated when the shunt calibration feature is invoked. It indicates the status

of the shunt calibration switch in the transmitter. The state of the shunt calibration (and LED)

should change each time the push-button on the front panel is depressed.

4.2 Receiver Box – Back Panel

The back panel of the receiver box contains

connector ports and adjustment controls as shown in

Figure 4.

The back panel connector ports and adjustment

controls are described in Table 3.

ADJUSTMENT

CONTROLS:

Adjusts various settings of the receiver box including: gain, zero offset, and filtering.

I/O

:

DB-25 connector for interface between the receiver box and a display meter or transient recorder.

DC IN

:

The connector port for the supplied power supply.

ANTENNA:

The connector port for the TNC side of the supplied 24 foot coaxial transmission cable.

The standard TORKDISCsystem is supplied with a 24 foot long coaxial cable designed to transmit signals from

the antenna assembly to the receiver box. This length is critical to proper operation of the TORKDISCsystem.

DO NOT SHORTEN IT. Any excess length should be coiled up. Consult the factory if additional cable length is

required.

ATTENTION

Figure 3 – Receiver Box Front Panel

Figure 4 – Receiver Box Back Panel

Table 2

–

Receiver Front Panel

Table 3

–

Receiver Back Panel

PCB Load & Torque Toll-Free in USA 866-684-7107 716-684-0001 www.pcb.com

16-BIT TORKDISCROTARY TORQUE SENSOR SYSTEM OPERATION MANUAL

7

4.3 Receiver Box – I/O Connector Pinouts

The outputs of the torque sensor are provided on the back of the receiver via the DB-25 connector labeled “I/O”

(see Figure 4). Table 4 defines the signals and pinouts of the connector.

VOLTAGE OUTPUT:

Pin 13

Analog system output. This output has an adjustable gain (see figure 5) to select

the desired full scale of the system.

Pin 25

Voltage Output Ground

DIFFERENTIAL FREQUENCY

OUTPUTS (optional):

Pins 17(+), 4(-)

Digital system output. These outputs are a differential signal that are referenced to

+5V and GROUND (TTL Compatible). It is recommended that this signal be

terminated using a 100Ωresistor on longer cable runs. When using the frequency

output, the receivers’ SYSTEM GAIN RANGE must be set to position A, and

adjusted to a full scale of ±10VDC (see Figure 5).

AC OUTPUT

(Capacitively Coupled):

Pin 12

The AC output has an adjustable high pass filter which will remove the DC and

lower frequency torque components. This filter is a two pole high pass Butterworth

filter with user selectable cutoff frequencies of approximately 5, 10, 20, 200, 500,

and 725 Hz.

Pin 24

AC Output Ground

ANALOG GROUND:

Pins 11, 23, 25

The analog ground is the reference for the voltage output. This analog ground is

isolated from the system ground and should not be connected to it.

DIGITAL GROUND:

Pins 7, 19

The digital ground is the reference for all digital inputs and outputs. This digital

ground is isolated from the analog ground and should not be connected to it.

TRANSMITTER LOW POWER

STATUS:

Pin 6

This is a digital (TTL level) output of the transmitter power low bit. This signal is

activated when the power at the transmitter is insufficient to operate the electronics.

HI = LOW POWER, LO = ADEQUATE POWER

SHUNT CALIBRATION

STATUS:

Pin 16

This is a digital (TTL level) output for the status of the shunt calibration feature.

HI = SHUNT ACTIVATED, LO = SHUNT CAL DEACTIVATED

DATA STATUS:

Pin 5

This is a digital (TTL level) output indicating that valid data is being received from

the transmitter. HI = VALID DATA, LO = INVALID DATA

SHUNT CALIBRATION

CONTROL:

Pin 16

For remote Shunt Calibration Control, a normally open, single pole, single throw

momentary push-button switch can be connected across pins 16 and 19.

MAIN CLOCK:

Pin 3

Main clock for the receiver, provided for QSPI

SERIAL DATA:

Pin 2

Digital data stream received from the transmitter and used for the QSPI

EXTERNAL QSPI BIT CLOCK:

Pin 14

QSPI clock signal

SLAVE SELECT:

Pin 1

QSPI timing signal

RESERVED:

Pins 8, 9, 10, 15, 20, 21, 22

N/C

Table 4

–

Receiver

I/O Connector Pinouts

& Signals

PCB Load & Torque Toll-Free in USA 866-684-7107 716-684-0001 www.pcb.com

16-BIT TORKDISCROTARY TORQUE SENSOR SYSTEM OPERATION MANUAL

8

4.4 Receiver Box – Adjustment Controls

The measured outputs can be adjusted via the controls on the rear of the receiver box as shown in Figure 5 and

defined in Table 5.

V

OUT

GAIN ADJUSTMENT:

Multi-turn potentiometer adjusts receiver output gains of the voltage. Preset at

factory to ±10VDC full-scale equals sensor full-scale input (mV/V). Not

recommended for user adjustment.

OFFSET ADJUSTMENT:

Multi-turn potentiometer adjusts output signal offset of the voltage and frequency.

Preset at factory for zero receiver offset. Not recommended for user

adjustment. The range of this adjustment is ±15% full-scale. If additional offset is

needed, refer to ZERO/ADDITIONAL OFFSET.

SYMMETRY ADJUSTMENT:

Multi-turn potentiometer allows a 0.5% of full-scale gain adjustment to either the

positive or negative portion of the receiver’s outputs. Preset at factory. Not

recommended for user adjustment.

SYSTEM GAIN RANGE

SELECTION:

Enables selection of 16 discrete gain ranges (see Table 6). Preset at factory. Not

recommended for user adjustment.

ZERO/ADDITIONAL OFFSET:

Used for setting the receiver to a forced zero output and additional offset

adjustment range (see Table 7).

AC GAIN SELECTION:

This adjustment allows the user to select gains for the AC output in integer steps

from 1 to 16. This will allow users to further process low level AC components of

the composite signal with greater resolution (see Table 8).

LOW PASS FILTER

SELECTION:

The high frequency limit of the bandwidth is controlled by an 8 pole elliptical low

pass filter in the receiver. This filter is adjustable via the rotary switch at the rear

access port of the receiver (see Table 10).

HIGH PASS FILTER

SELECTION:

The AC output has an adjustable high pass filter which will remove the DC and

lower frequency torque components. This filter is a two pole high pass Butterworth

filter with user selectable cut-off frequencies of approximately 5, 10, 20, 200, 500,

and 725 Hz (see Table 11).

AC Gain

Selection

Low Pass

Filter

Selection

High Pass

Filter

Selection

V

OUT

Gain

Adjustment

Offset

Adjustment

Symmetry

Adjustment

System

Gain Range

Adjustment

Zero /

Additional

Adjustment

Figure 5 – Receiver Adjustments and Controls

Table 5 – Receiver Adjustments and Controls

Manipulating the output adjustment controls will affect the measurement readings and should only be performed by

trained personnel. Contact the factory with any questions or concerns about these controls and settings prior to

adjusting.

ATTENTION

PCB Load & Torque Toll-Free in USA 866-684-7107 716-684-0001 www.pcb.com

16-BIT TORKDISCROTARY TORQUE SENSOR SYSTEM OPERATION MANUAL

9

4.4.1 System Gain Range

Use the following equation to determine the System Gain switch setting.

Example:

NOMINAL_GAIN = 1.373 Looking at the values in Table 6, the System Gain Range

should be set to position E or F.

Table 6 describes the Zero/Added Offset switch settings

SWITCH SETTING MINIMUM GAIN NOMINAL GAIN MAXIMUM GAIN

0 0.222 0.257 0.292

1 0.284 0.328 0.372

2 0.351 0.406 0.461

3 0.413 0.477 0.542

4 0.465 0.537 0.610

5 0.526 0.608 0.691

6 0.594 0.686 0.779

7 0.655 0.758 0.860

8 0.756 0.874 0.992

9 0.817 0.945 1.072

A* 0.885 1.023 1.161

B 0.946 1.094 1.242

C 0.998 1.154 1.310

D 1.060 1.225 1.391

E 1.127 1.303 1.479

F 1.189 1.374 1.560

*For Frequency Output

The System Gain Range is set at the factory for optimum performance of the TORKDISCsystem. Adjusting the

switch settings may have adverse effects on the measurement values. This setting is not recommended for user

adjustment.

ATTENTION

Table 6 – System Gain Range Switch Settings

PCB Load & Torque Toll-Free in USA 866-684-7107 716-684-0001 www.pcb.com

16-BIT TORKDISCROTARY TORQUE SENSOR SYSTEM OPERATION MANUAL

10

4.4.2 Zero/Additional Offset

Table 7 describes the Zero/Additional Offset switch settings.

SWITCH POSITION

MODE

1

2

3

OFF OFF OFF Normal operation: Offset adjustment +/- 15% of full scale

ON OFF OFF Zero Out Mode: Receiver will output digital zero regardless of transmitter operation. Useful for

setting receiver offset adjustment to zero (no added offset correction).

OFF ON OFF Adds +25% of full-scale to the offset adjustment for a total of + 40% of full-scale

OFF OFF ON Adds -25% of full-scale to the offset adjustment for a total of -40% of full-scale

4.4.3 AC Gain

Table 8 lists the available gain settings for the AC Gain selection switch. This gain is independent from the DC

coupled voltage output and provides additional gain to the AC coupled output (see Figure 5).

Table 7

–

Zero/Add

itional

Offset

Table 8

–

AC Output Gain

SWITCH SETTING

NOMINAL GAIN

0 1.0

1 2.0

2 3.0

3 4.0

4 5.0

5 6.0

6 7.0

7 8.0

8 9.0

9 10.0

A 11.0

B 12.0

C 13.0

D 14.0

E 15.0

F 16.0

Placing both switches 2 and 3 of the Zero/Additional Offset switch to the ON position will null each other and provide

no added offset.

ATTENTION

PCB Load & Torque Toll-Free in USA 866-684-7107 716-684-0001 www.pcb.com

16-BIT TORKDISCROTARY TORQUE SENSOR SYSTEM OPERATION MANUAL

11

4.4.4 Low & High Pass Filters

Figure 6 shows the signal path on both the AC and DC voltage outputs and how they are influenced by the filter

and gain settings.

4.4.4.1 Low Pass Filter

Figure 7 shows low pass filter plots of the transmitter only, receiver only, and the composite of

transmitter and receiver combined.

Figure 6 – Signal Path to I/O Connector

Figure 7 –Low Pass Filter Plots

Number

DESCRIPTION

1 Transmitter Only

2 Receiver Only

3 Transmitter & Receiver

Composite

Table 9

–

Low Pass

Filter

Plots

PCB Load & Torque Toll-Free in USA 866-684-7107 716-684-0001 www.pcb.com

16-BIT TORKDISCROTARY TORQUE SENSOR SYSTEM OPERATION MANUAL

12

4.4.4.2 Composite Low Pass Filter

Figure 8 compares low pass filter plots for both the voltage output per pins 13 & 25 and the AC outputs

per pins 12 & 24 on the DB-25 I/O connector.

NOTE: The low pass filter switch controls the low pass filtering for both the DC and AC coupled

outputs.

Table 10 lists the available cut-off frequency settings for the low pass filter switch as shown in Figure 8.

Table 10 – Low Pass (AC & DC) Analog Output Filter Settings (composite output)

Figure 8 – Composite Low Pass Filter Plots for Both Outputs

SWITCH SETTING

FREQUENCY Hz (

-

3dB)

0 1

1 10

2 313

3 625

4 1250

5 2500

6 5000

7 8500

PCB Load & Torque Toll-Free in USA 866-684-7107 716-684-0001 www.pcb.com

16-BIT TORKDISCROTARY TORQUE SENSOR SYSTEM OPERATION MANUAL

13

4.4.4.3 Composite High Pass Filter

Figure 9 compares high pass filter plots for the AC output for pins 12 & 24 on the DB-25 I/O connector.

Table 11 lists the available cut-off frequency settings for the high pass filter switches as shown in Figure

9.

Figure 9 – Composite High Pass Filter Plots for the AC Output

Table

11

–

High Pass (A

C Coupled

)

Analog Output Filter Settings

NUMBER

SWITCH SETTING

FREQUENCY Hz

(-3dB)

1

2

3

4

1 OFF OFF OFF OFF 5

2

ON

OFF OFF OFF 10

3 OFF

ON

OFF OFF 20

4 OFF OFF

ON

OFF 200

5 OFF OFF OFF

ON

500

6

ON

ON

ON

ON

725

PCB Load & Torque Toll-Free in USA 866-684-7107 716-684-0001 www.pcb.com

16-BIT TORKDISCROTARY TORQUE SENSOR SYSTEM OPERATION MANUAL

14

5.0 MECHANICAL INSTALLATION

5.1 TORKDISCInstallation

1. The TORKDISCis designed to be installed between a prime mover and a load, such as a combustion

engine and a dynamometer. A total of two degrees of freedom is required between the TORKDISC

and mating components to accommodate minor misalignment that may occur after installation. The

required two degrees of freedom can be provided on one end of the torque sensor or can be divided up to

one degree per end.

2. In most applications, we recommend that the

female pilot end of the TORKDISCbe hard-

coupled to the dynamometer, and the male pilot

end be connected to the test article by means of

a flexible coupling. Automotive-style drive

shafts with a universal or constant velocity

joint at each end are acceptable (see Figure 10).

When using a drive shaft with universal joints

at each end, a slip yoke at one end is desirable

to prevent axial forces from being transmitted

to the TORKDISC. It is also important that

the universal joints are in phase end-to-end,

and drive shafts run 2 to 3 degrees out of level

end-to-end. If preferred, commercially

available flexible couplings are acceptable

alternatives.

Figure 10 – Typical Installation

TORKDISC

Dynamometer

Customer Supplied

Fixtures & Adapters

Test Article

Proper mechanical installation of the TORKDISCrotary torque sensor system is critical to ensure proper operation

and long-term life. Read this entire section before installing the system. When in doubt about application, consult

the Load & Torque Division of PCB Piezotronics prior to proceeding.

CAUTION

This wireless data acquisition system contains delicate electronic components that must be protected from excessive

shock and prolonged exposure to water, oil, or other chemical contaminants. All electrical connections must be well

protected from electrostatic discharge by using protective wrist straps during installation.

CAUTION

CAUTION

DO NOT USE AN IMPACT WRENCH

WHEN INSTALLING THIS PRODUCT!

PCB Load & Torque Toll-Free in USA 866-684-7107 716-684-0001 www.pcb.com

16-BIT TORKDISCROTARY TORQUE SENSOR SYSTEM OPERATION MANUAL

15

3. Connecting drive shafts usually can be bolted directly to the TORKDISCthrough use of an adapter,

without need for additional support, assuming that the resultant bending moment on the TORKDISC

does not exceed the specified limit. Request specification sheets from PCB to determine the maximum

permissible bending moment of a given TORKDISCmodel.

4. Mechanically align the connecting drive shaft(s) as accurately as possible to minimize the effects of

parallel offset of shafts, angular misalignment, and shaft end float.

5. Drive shaft run-out ideally should not exceed 0.001 inches, as excessive run-out (>0.002 inches) will

multiply the static bending moment, and may exceed the sensor’s bending moment capability.

6. The TORKDISCwill produce a positive output when a clockwise torque is applied to the input end

(male pilot end). Counterclockwise torque will produce a negative output

7. The stationary antenna assembly (stator) of the TORKDISCis designed to be installed directly over

the rotating sensor assembly (rotor) to transmit excitation and digitized torque data. Center the loop

such that the rotor and stator do not touch. The top portion of the stator can be removed to aid

installation, if desired. The base of the stator is designed to be bolted to a rigid support structure in any

orientation around the rotor, but is typically installed at the six o’clock position.

8. Careful attention is required when installing

the stator, as the loop portion that surrounds

the non-contacting rotor requires a minimum

of a 0.5-inch axial air gap between it and any

nearby metallic surfaces (see Figure 11).

9. The supplied signal conditioning electronics

(receiver) is designed to be installed in a

clean, temperature-controlled (70°F, ±10°)

environment, usually outside the test cell in a

cabinet or console. Mounting feet are

provided to secure the receiver to a panel or

shelf.

10. Typically a 24 ft (7.3 m) TNC plug to BNC

plug cable is supplied to connect the receiver to

the stator assembly. This cable is an integral

component to the TORKDISCsystem, and

the cable must not be shortened, nor should

additional cable be added. Be sure to coil any

excess cable, and consult PCB Piezotronics if a

longer cable length is required.

TORKDISC

0.500

in (12.7 mm) min,

Air Gap Required

Telemetry

Collar

Mating

Adaptor

Mating

Adaptor

Figure 11 – Stator Loop Air Gap

Other manuals for TORKDISC 5308D-02A

1

Table of contents

Other PCB Security Sensor manuals

PCB

PCB 2303-01A User manual

PCB

PCB 2301-02A User manual

PCB

PCB LOAD & TORQUE 2508-01A User manual

PCB

PCB Piezotronics 4115A-05A User manual

PCB

PCB 2301-01A User manual

PCB

PCB 2302-02A User manual

PCB

PCB Load & Torque 4115K-13A User manual

PCB

PCB 2302-01A User manual

PCB

PCB 4115K-06A User manual

PCB

PCB TORKDISC 5302D-01A User manual

Popular Security Sensor manuals by other brands

Preferred

Preferred JC-30D Installation and operation manual

Rosslare

Rosslare PYR-3011 installation manual

Honeywell

Honeywell Friedland FGGA08 Series Quick installation guide

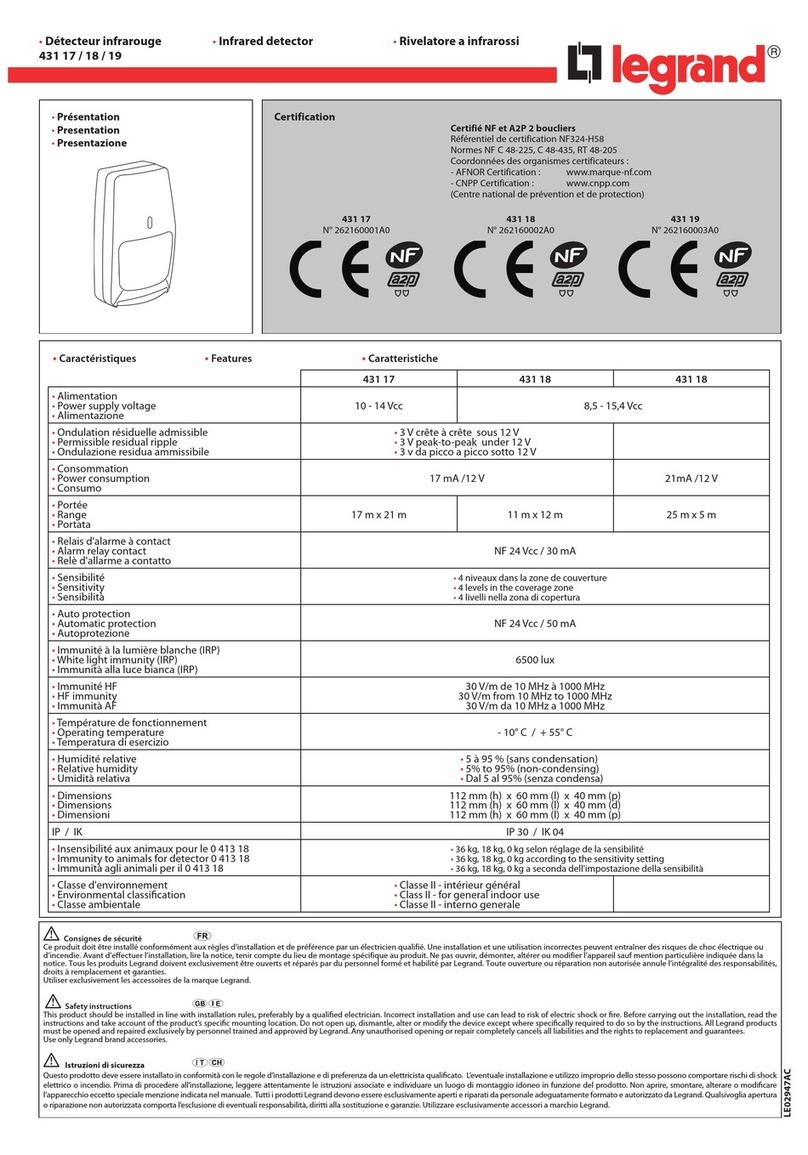

LEGRAND

LEGRAND 431 17 manual

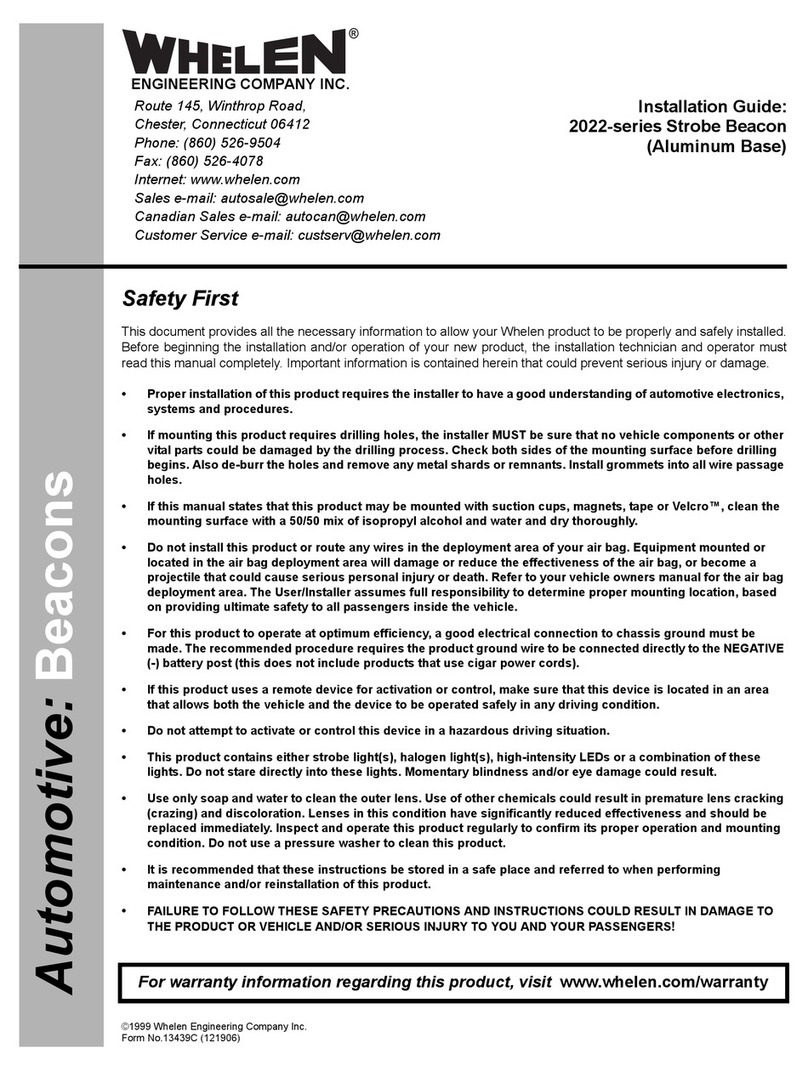

Whelen Engineering Company

Whelen Engineering Company 2022 Series installation guide

Emos

Emos G1240 manual