Manual

Table of figures

Fig. 1 Installation of PCE-MWM 210.................................................................................................................................7

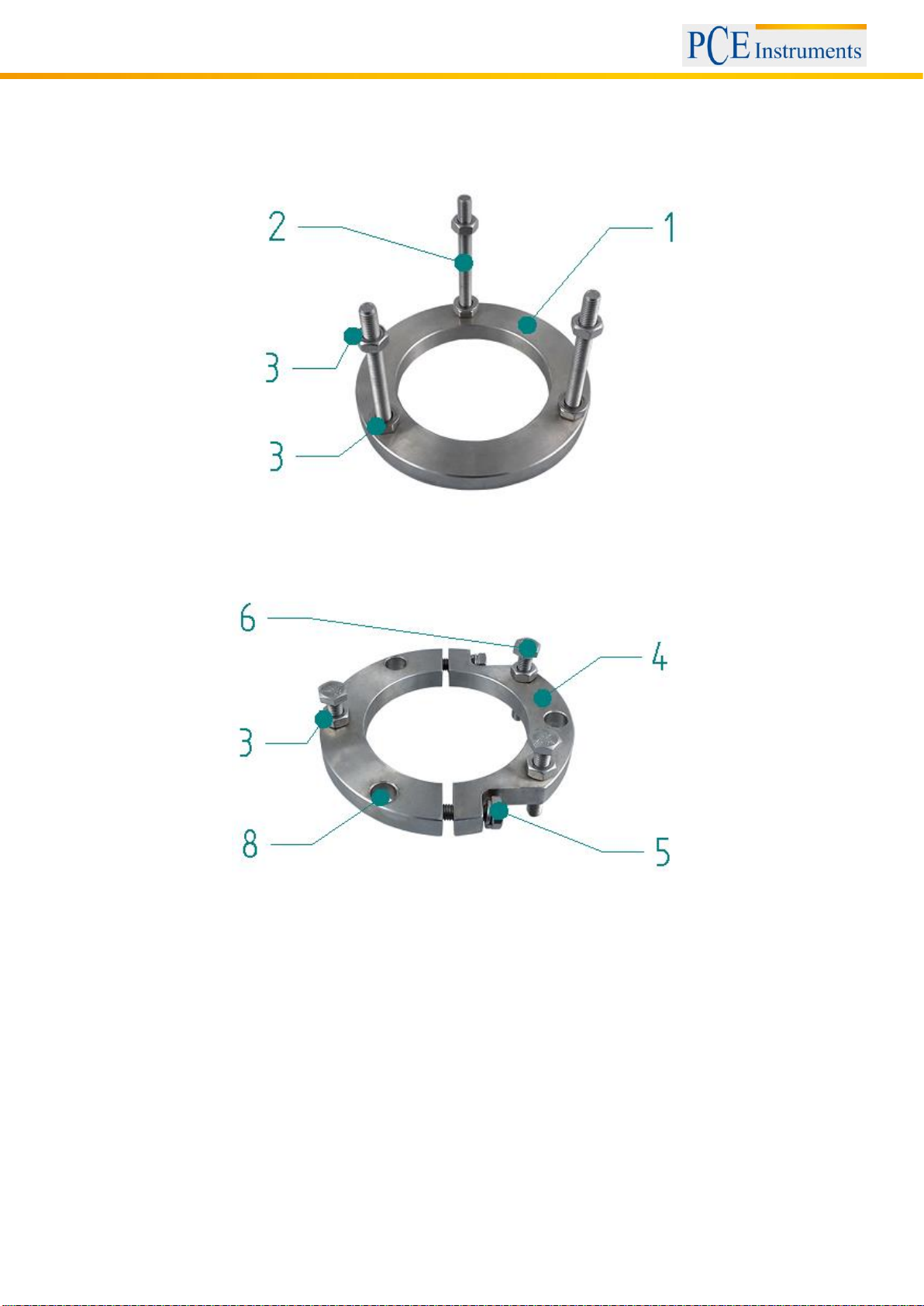

Fig. 2 Welding flange ........................................................................................................................................................8

Fig. 3 Clamping ring..........................................................................................................................................................8

Fig. 4 Sensor fixed in ring-assembly.................................................................................................................................9

Fig. 5 Ring-assembly ........................................................................................................................................................9

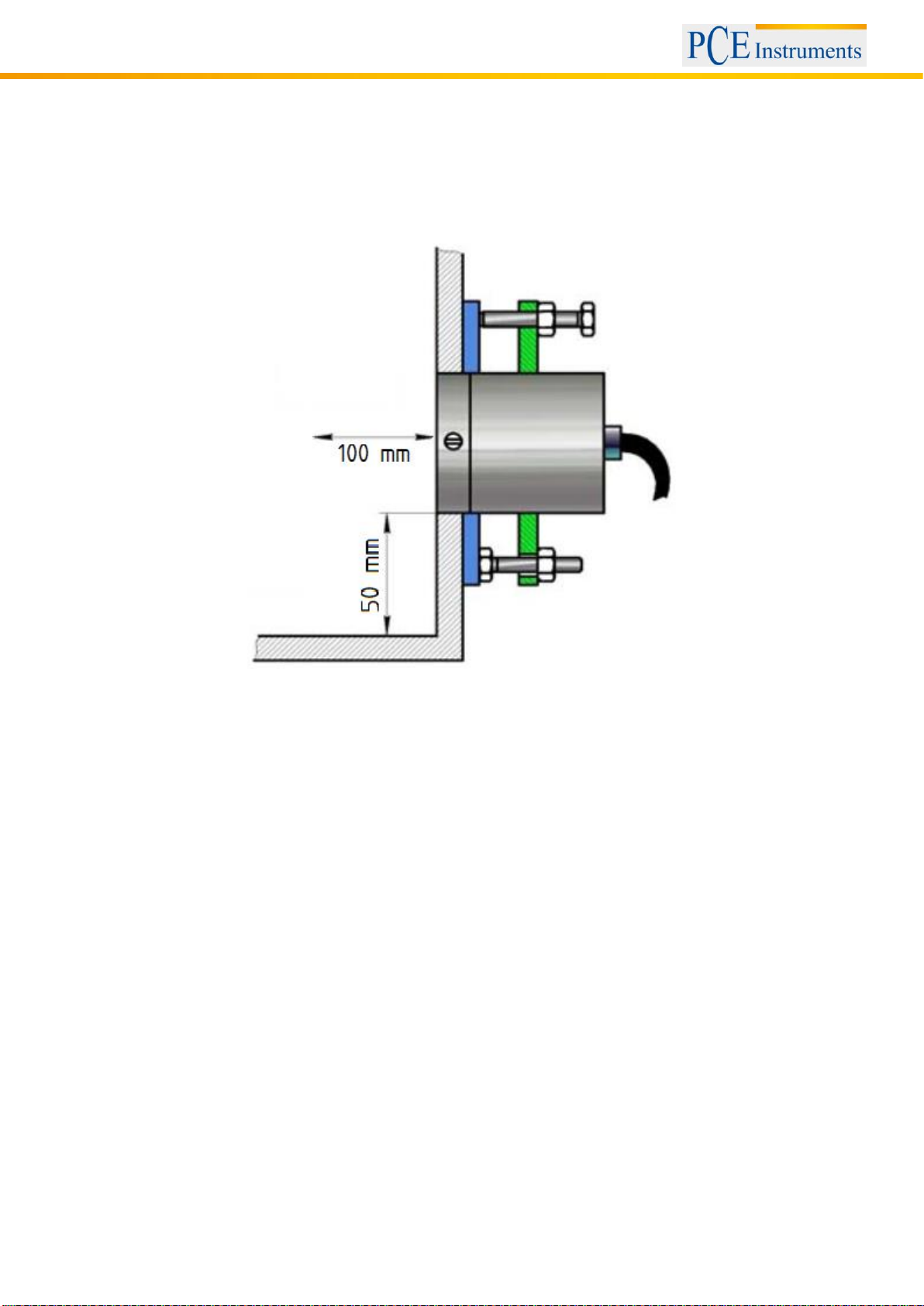

Fig. 6 Distance of PCE-MWM 210 to metallic components............................................................................................10

Fig. 7 Dimensions of the base plate of the moisture sensor PCE-MWM 240A ..............................................................11

Fig. 8 Dimensions of the rectangular cut-out ..................................................................................................................12

Fig. 9 Installation with welds ...........................................................................................................................................12

Fig. 10 Dimensions of the rectangular cut-out ................................................................................................................13

Fig. 11 Installation with screws .......................................................................................................................................13

Fig. 12 Dimensions of the rectangular cut-out ................................................................................................................14

Fig. 13 Dimensions of the flange for installation of the moisture sensor PCE-MWM 240A............................................14

Fig. 14 Installation on a curved surface ..........................................................................................................................15

Fig. 15 Sufficient material coverage of the moisture sensor PCE-MWM 240A..............................................................16

Fig. 16 Insufficient material coverage of the moisture sensor PCE-MWM 240A............................................................16

Fig. 17 Components of the moisture sensor PCE-MWM 240B ......................................................................................17

Fig. 18 Dimensions of the welding flanges .....................................................................................................................17

Fig. 19 Installation of the moisture sensor PCE-MWM 240B..........................................................................................18

Fig. 20 Sufficient material coverage of the moisture sensor PCE-MWM 240B..............................................................19

Fig. 21 Insufficient material coverage of the moisture sensor PCE-MWM 240B............................................................19

Fig. 22 M12 connector ....................................................................................................................................................21

Fig. 23 Wiring diagram....................................................................................................................................................21

Fig. 24 Pin assignment....................................................................................................................................................21

Fig. 25 Core identification code.......................................................................................................................................22

Fig. 26 Pin assignment for power supply........................................................................................................................22

Fig. 27 M12 connector ....................................................................................................................................................23

Fig. 28 Wiring diagram....................................................................................................................................................23

Fig. 29 Pin assignment....................................................................................................................................................24

Fig. 30 Core identification code.......................................................................................................................................24

Fig. 31 Pin assignment for signal output.........................................................................................................................24

Fig. 32 Pin assignment for analog output .......................................................................................................................25

Fig. 33 Pin assignment for serial port RS-485 ................................................................................................................26

Fig. 34 Calibration curves for different material ..............................................................................................................28

Fig. 35 PCE-MWM Manager main window.....................................................................................................................29

Fig. 36 Configuring RS-485 converter ............................................................................................................................30

Fig. 37 Settings ...............................................................................................................................................................31

Fig. 38 Successful connection ........................................................................................................................................31

Fig. 39 Message about missing initial calibration............................................................................................................31

Fig. 40 Configuration electronic unit ...............................................................................................................................32

Fig. 41 Dialog for initial calibration..................................................................................................................................32

Fig. 42 Initial calibration successful ................................................................................................................................32

Fig. 43 Tree view of calibrations .....................................................................................................................................33

Fig. 44 Window for new calibration.................................................................................................................................33

Fig. 45 Calibration table ..................................................................................................................................................34

Fig. 46 Warning if measured temperature of recorded date exceeds threshold.............................................................34

Fig. 47 Calibration table with first entry...........................................................................................................................35

Fig. 48 Assign moisture to sensor data...........................................................................................................................35

Fig. 49 Calibration table with multiple measurements ....................................................................................................36

Fig. 50 Calibration with high accuracy ............................................................................................................................37

Fig. 51 Calibration with reduced accuracy......................................................................................................................37

Fig. 52 Flawed calibration...............................................................................................................................................38

Fig. 53 Transfer calibration to electronic unit..................................................................................................................38

Fig. 54 Transfer best-fit line from electronic unit.............................................................................................................39

Fig. 55 Imported best-fit line from electronic unit displayed in the tree view ..................................................................39

Fig. 56 Currently selected calibration in the electronic unit ............................................................................................40

Fig. 57 Status bar for Test...............................................................................................................................................40