CONTENTS

1. Main specifications ............................................................................... 2

2. Dimensions ........................................................................................... 3

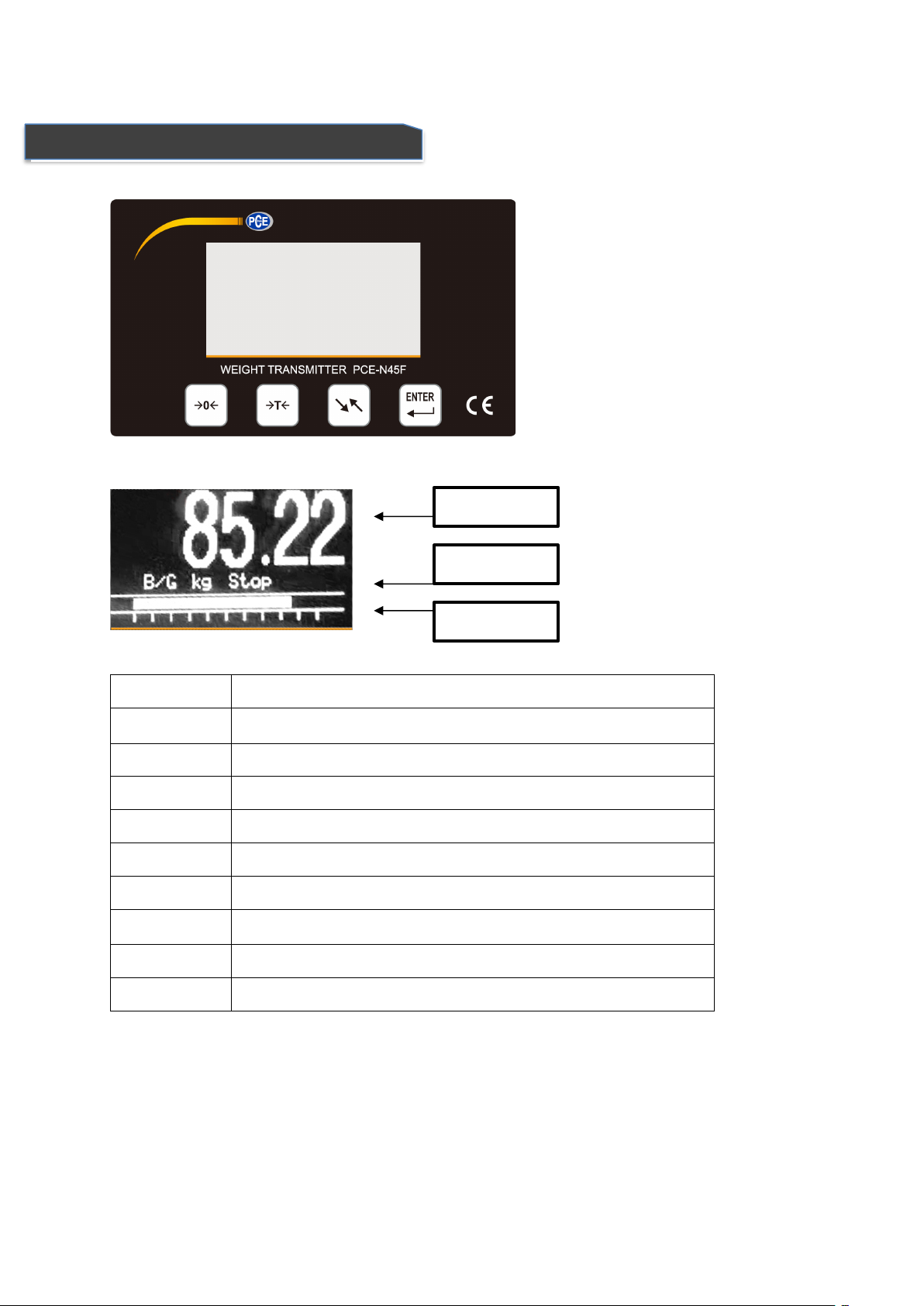

3. Front Overlay and Keypad .................................................................... 4

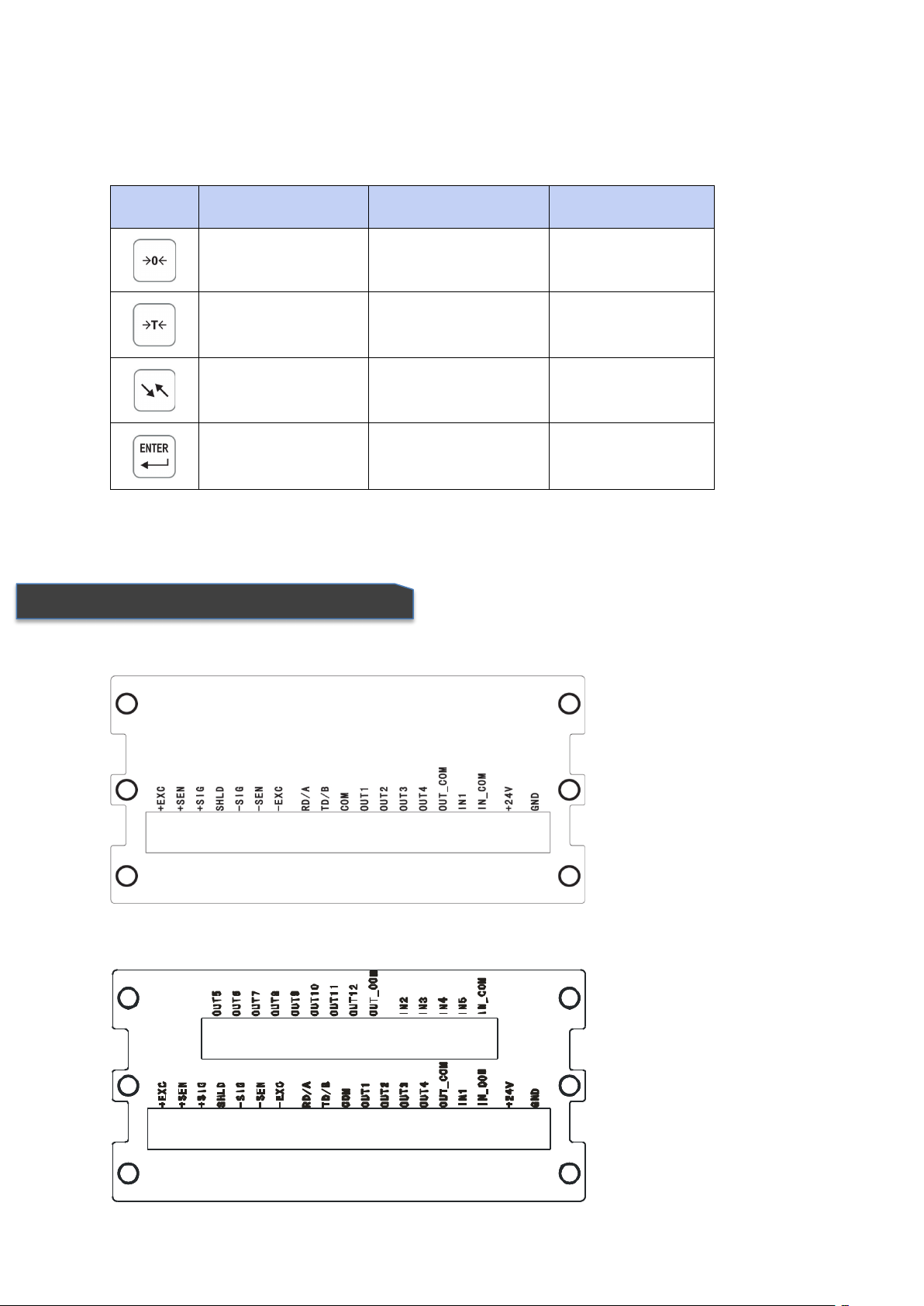

4. Rear Back Interface ............................................................................... 5

5. Load Cell Interface ................................................................................ 6

6. Serial Interface ...................................................................................... 7

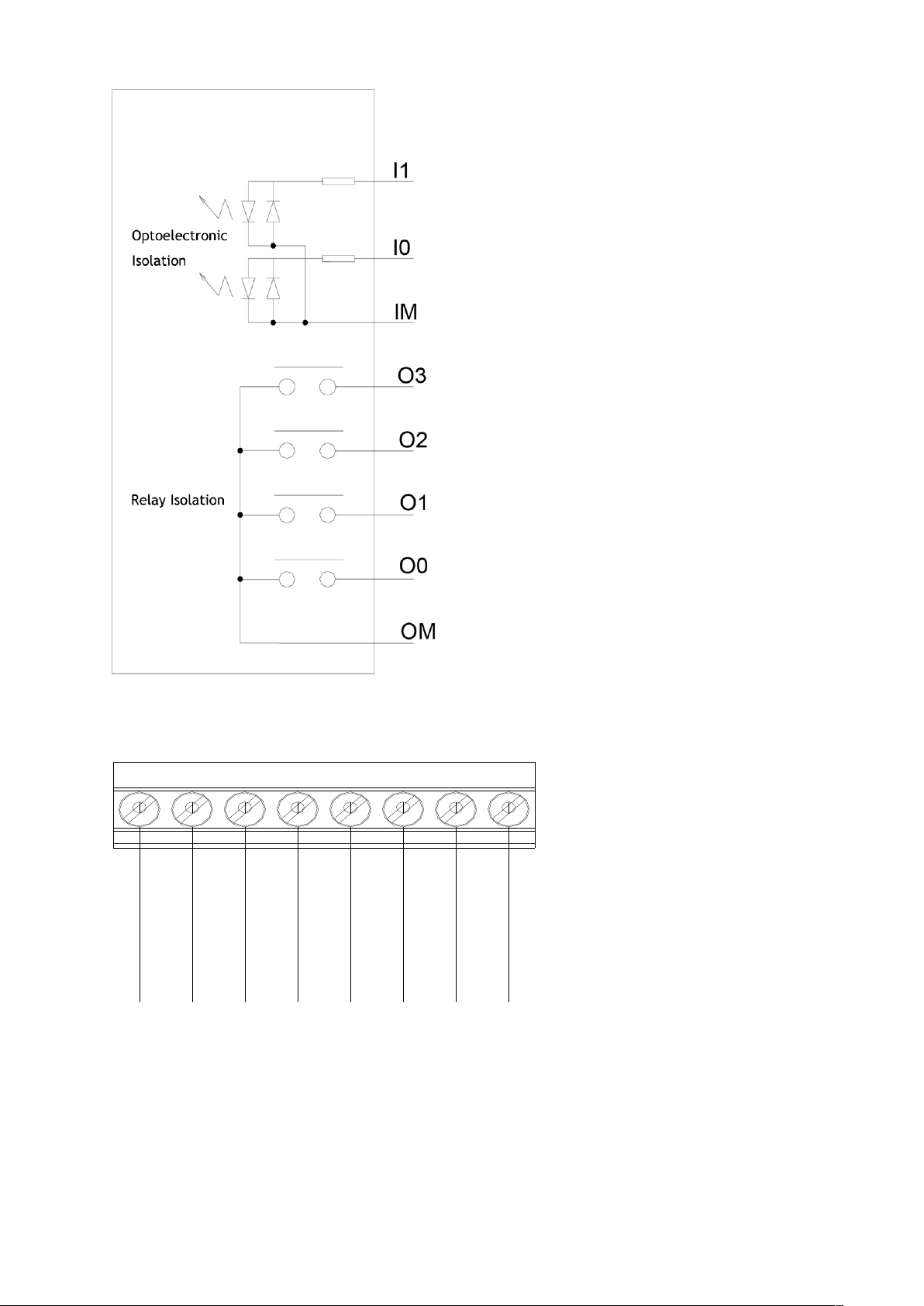

7. I/O ......................................................................................................... 7

8. Analog Quantity Output ....................................................................... 9

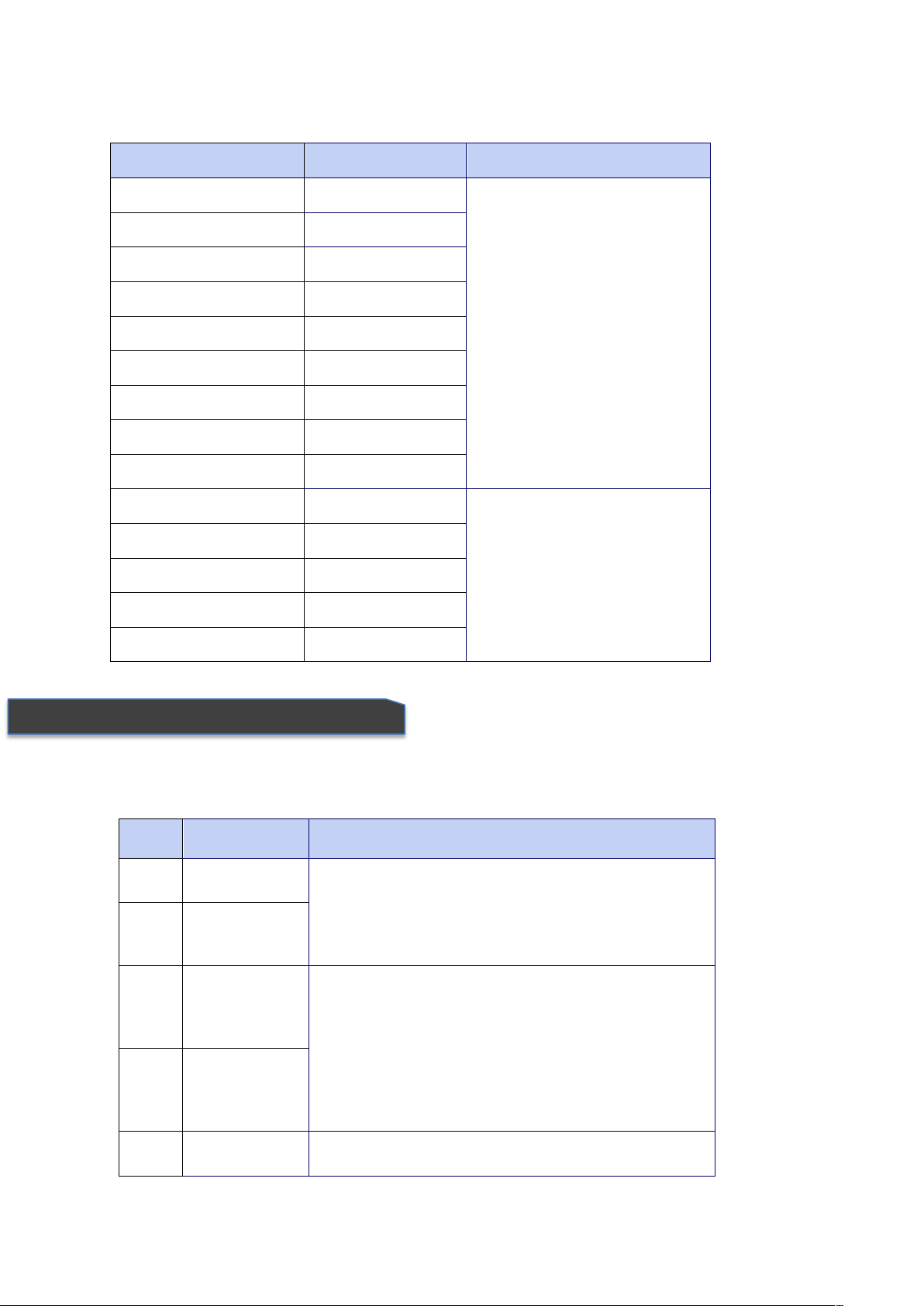

9. Parameter Set ..................................................................................... 10

9.1 Enter setting menu ........................................................................................ 10

9.2 Quit Setting .................................................................................................... 10

9.3 Main Set Menu .............................................................................................. 10

9.4 System Parameter Set ................................................................................... 10

9.4.1 Scale Set ................................................................................................................ 11

9.4.2 Operation Set ....................................................................................................... 14

9.4.3 Batching Set .......................................................................................................... 17

9.4.4 Communication protocol ...................................................................................... 23

9.4.5 Analog quantity output ........................................................................................ 25

9.4.6 Diagnosis and maintenance .................................................................................. 26

9.5 Recipes Parameters set ................................................................................. 31

9.6 Printing table format ..................................................................................... 35

9.7 System set ...................................................................................................... 35

10. Appendix: Communication Protocol ................................................. 36

10.1 Continuous transmitting format A .................................................. 36

10.1 Command transmitting Format A ............................................................. 36

10.2 Command transmitting format A ............................................................. 37

10.3 Continuous transmit format B .................................................................. 37

10.4 Command output format B ...................................................................... 37

10.5 MODBUS output format .............................................................................. 38

10.6 Multi materials jointed work with relay connected ................................. 41