Index

1GENERAL .......................................................................................................................................3

1.1 Software Operation....................................................................................................................3

1.2 Software License Agreement.....................................................................................................3

1.3 Safety regulations......................................................................................................................4

1.4 System Requirements ...............................................................................................................4

2GENERAL HANDLING INSTRUCTIONS........................................................................................5

2.1 Operation mode.........................................................................................................................5

2.2 To connect / change sensors.....................................................................................................5

2.3 Zero correction of the pressure sensor ('OFFS')........................................................................5

2.4 Slope correction of the pressure sensor ('SCAL').......................................................................5

2.5 Pressure connection to the pressure sensor..............................................................................5

2.6 Advice for calibration service.....................................................................................................6

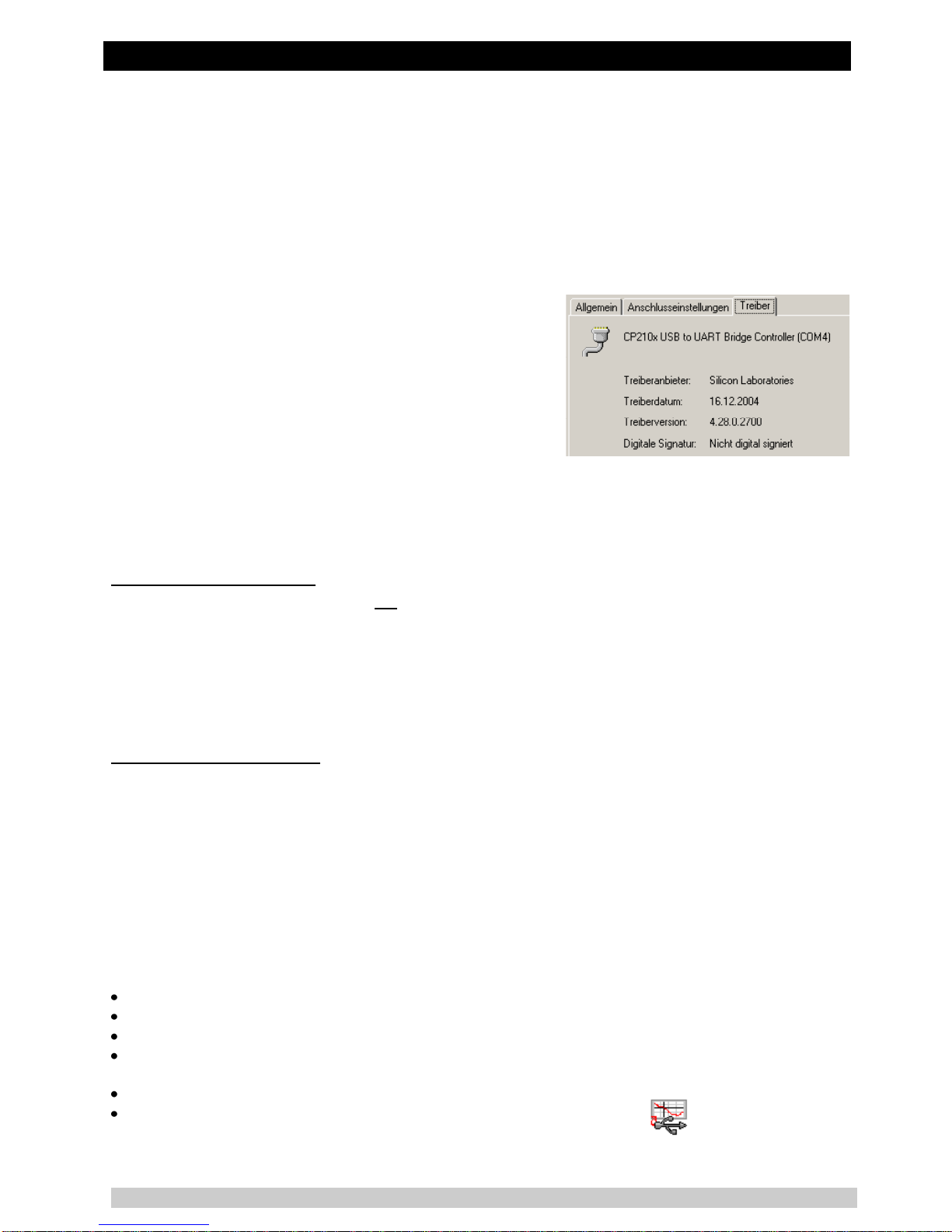

3DRIVER INSTALLATION ................................................................................................................6

3.1 Windows 2000, Windows XP, Windows Vista Windows 7 ...............................................6

4FREQUENTLY ASKED QUESTIONS (FAQ)...................................................................................6

4.1 How to check, whether the adapter has been installed correctly and via which COM-port can I

approach the installed adapter?..................................................................................................6

4.2 How to change the COM-port of the adapter? ...........................................................................6

4.3 Is there an automatic update function that updates the installed driver to the latest version?.....6

4.4 How to find out the used version of the driver?..........................................................................7

4.5 How to update a driver of an older version or how to uninstall the driver?..................................7

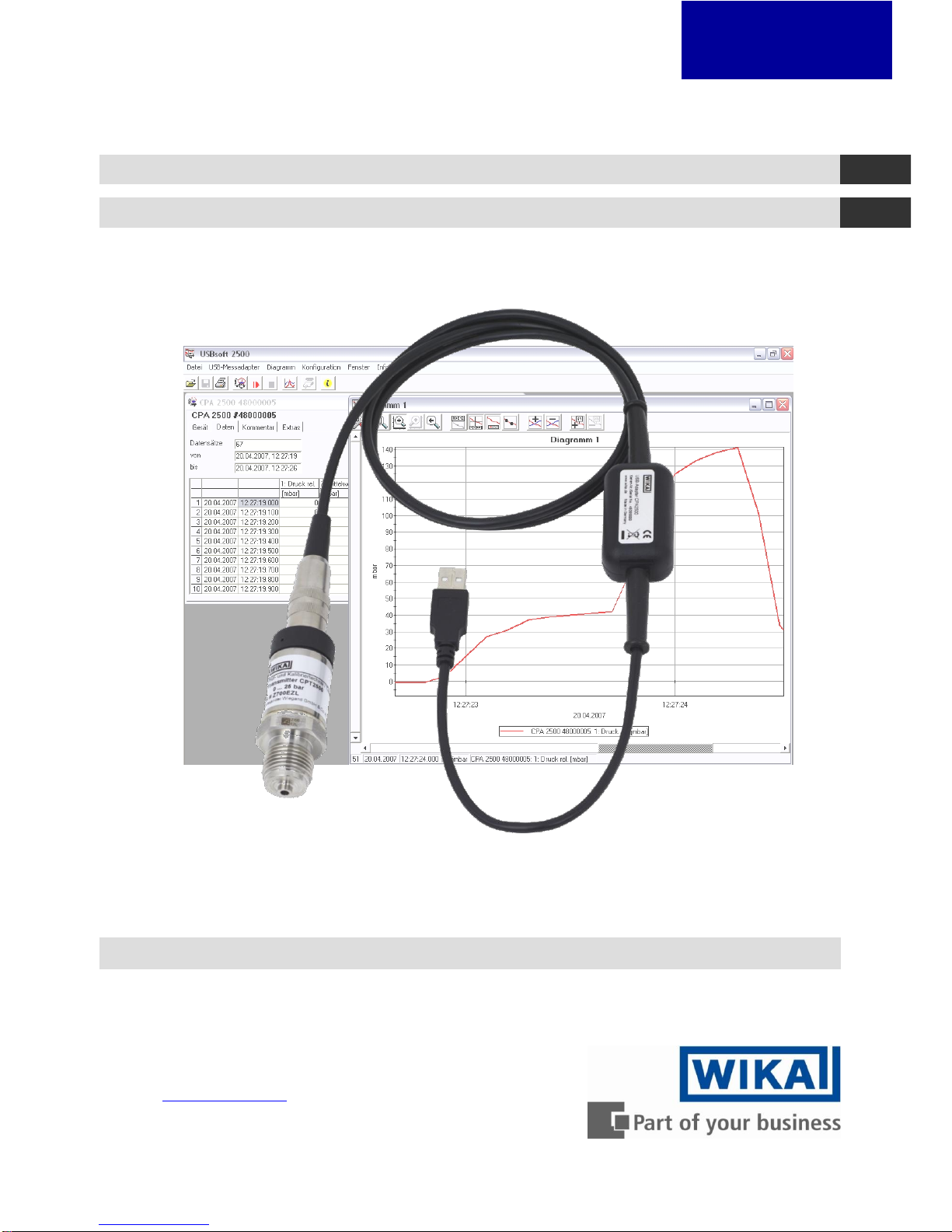

5OPERATING SOFTWARE USBSOFT2500.....................................................................................7

5.1 Software Installation ..................................................................................................................7

5.2 Screen Elements.......................................................................................................................8

5.2.1 Menu bar.............................................................................................................................8

5.2.2 Toolbar................................................................................................................................8

5.3 Data Recording..........................................................................................................................8

5.3.1 Connecting the USB-Adapter..............................................................................................8

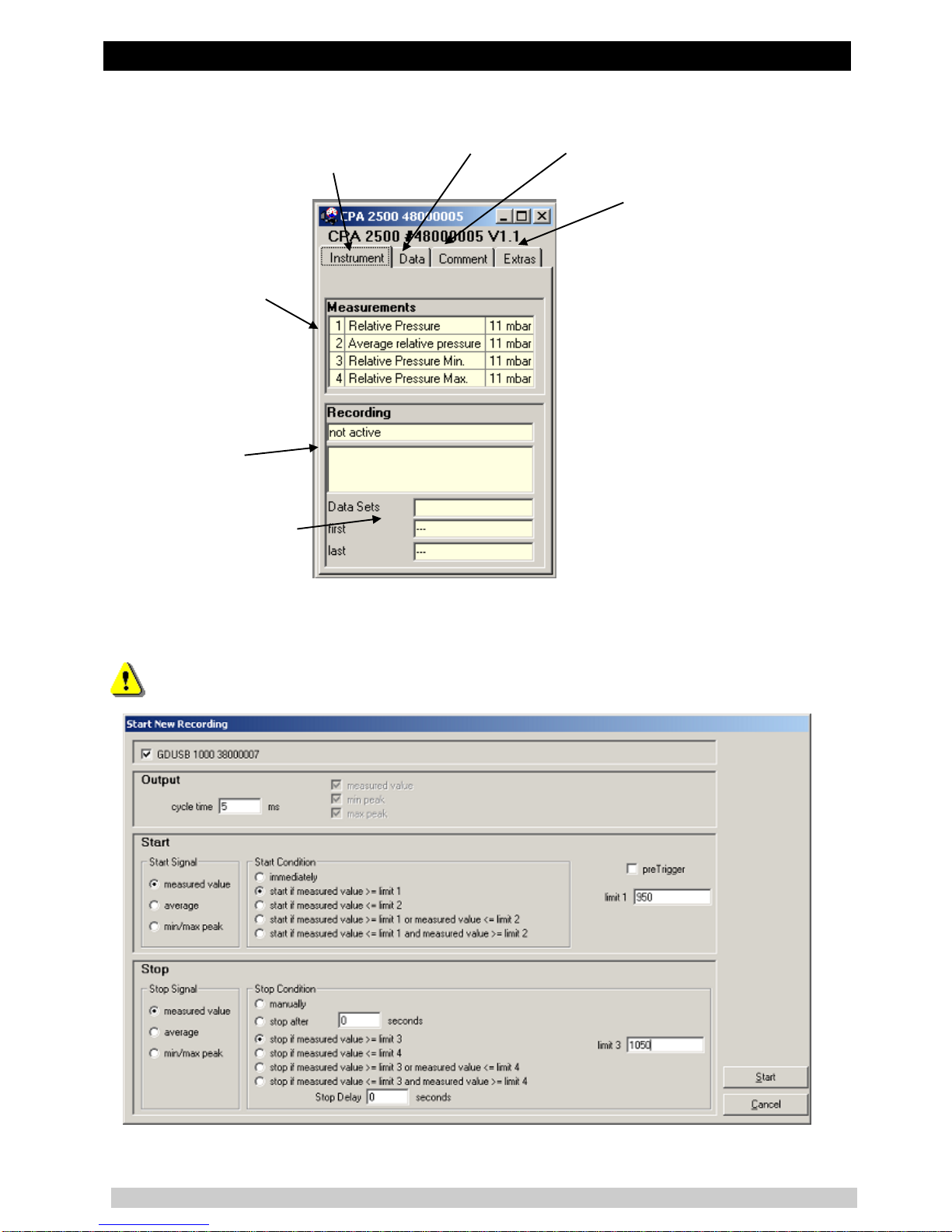

5.3.2 Sensor Data Screen............................................................................................................9

5.3.3 Start Recording...................................................................................................................9

5.3.4 Displaying the Measurements...........................................................................................10

5.3.5 Stop Recording .................................................................................................................10

5.3.6 Comment ..........................................................................................................................11

5.3.7 Extras................................................................................................................................11

5.4 File Operation..........................................................................................................................11

5.5 Print Data ................................................................................................................................12

5.6 Measurement Diagrams ..........................................................................................................12

5.6.1 Adding Data Labels...........................................................................................................13

5.6.2 Adding Series....................................................................................................................13

5.6.3 Zoom-function...................................................................................................................13

5.6.4 Copying Data to Clipboard................................................................................................13

6SPECIFICATION ...........................................................................................................................14

7DISPOSAL INSTRUCTIONS.........................................................................................................15