PDi 872 User manual

OPERATING INSTRUCTIONS

Model

872

DIGITAL

MULTIMETER

CONTENTS INTRODUCTION

Thismanualcontains informationandwarnings which mustbefollowed

to ensure safe operation and retain the meter in safe condition.

WARNING

READ "SAFETY INFORMATION" BEFORE

USING

THE

METER.

This multimeter is a handheld, 4000-count instrument that is designed

for use in the laboratory, field servicing, and at home. The meter

I

combines the precision of a digital multimeter with the high speed and

versatility of a analogdisplay. Thismeter featurescompactdesign with

rounded corners for easy handling and has a rugged case in shock

resistant and fire-retardant. Electronic overload protection for all

functions and ranges. The Protective Holster (optional accessory)

combined with rugged casemake it a durableand reliable instrument.

UNPACKING AND INSPECTION

Upon removingyournew Digital MuItimeter(DMM) from itspacking,

you should have the following items:

1.

Digital Multimeter

2. Test Lead Set (oneblack, one red)

'

3. 9-Volt Battery (installed in meter)

4.

Beaded Thermocouple Wire

5. Instruction Manual

6.

OneSpare Fuse (500mA/600V, 6.3mm

x

25mm, fast acting)

f

If

any of the above items are missing or are received in a damaged

cond~tion,please contact thedistributorfrom whom you purchased the

unit.

SAFETY

INFORMATION

Injury ordeath can occureven with low voltages and low currents. It is

extremely importantthatyou read thesesafety informationbeforeusing

your multimeter. Follow all safety practices and proper operating

procedures for equipment being tested.

1.

Exercise extremecaution when:

Measuring voltage above 20 volts, measuring current greater than

IOmA, measuring AC power line with inductive loads, measuring

AC power line during electrical storms.

2.

Always inspect your DMM, test leads and accessories for any sign

of damage or abnormality before every use. If any abnormal

conditions exist (i.e., broken or damaged test leads, cracked case,

display not reading, etc.), donot attempt to takeany measurements.

3.

Neverground yoilrselfwhen taking electrical measurements.Donot

touch exposed metal pipes, outlets, fixtures, etc., which might be at

ground potential. Keepyour body isolated fromground byusing dry

clothing, rubber shoes, rubber mats, or any approved insulating

material.

4.

Never touch exposedwiring, connections,testprobetips, oranylive

circuit conductors when attempting to make measurements.

5.

Never replace the protective fuse insidethe DMM with afuseother

than the specified orapproved equal fuse.

6.

Do not operate this instrument in an explosive atmosphere (i.e., in

the presence of flammable gases or fumes, vapor or dust.)

7.

Measuring voltage which exceeds the limits of the multimeter may

damagethemeter and exposetheoperator toashockhazard. Always

recognizethemetervoltagelimits asstated onthefrontofthemeter.

8.

Never apply more than SOOVDC between the COMjack and earth

ground.

9.

Never touch a voltage source when the test leads are plugged into

a

current jack.

10. When testing for the presence of voltage orcurrent, make surethe

voltageorcurrent ranges are functioning correctly. Takea reading

of a known voltage or current before assuming a zero reading

indicates no current or voltage.

SYMBOL

EXPLANATION

9

-L

-

-

-

,,

,

14

I))

Attention! Refer to the Operating Instructions

Dangerous Voltage May Be Present at terminals

Ground

AC

-

Alternating Current

DC

-

Direct Current

Diode

Audible Continuity

Double Insulation

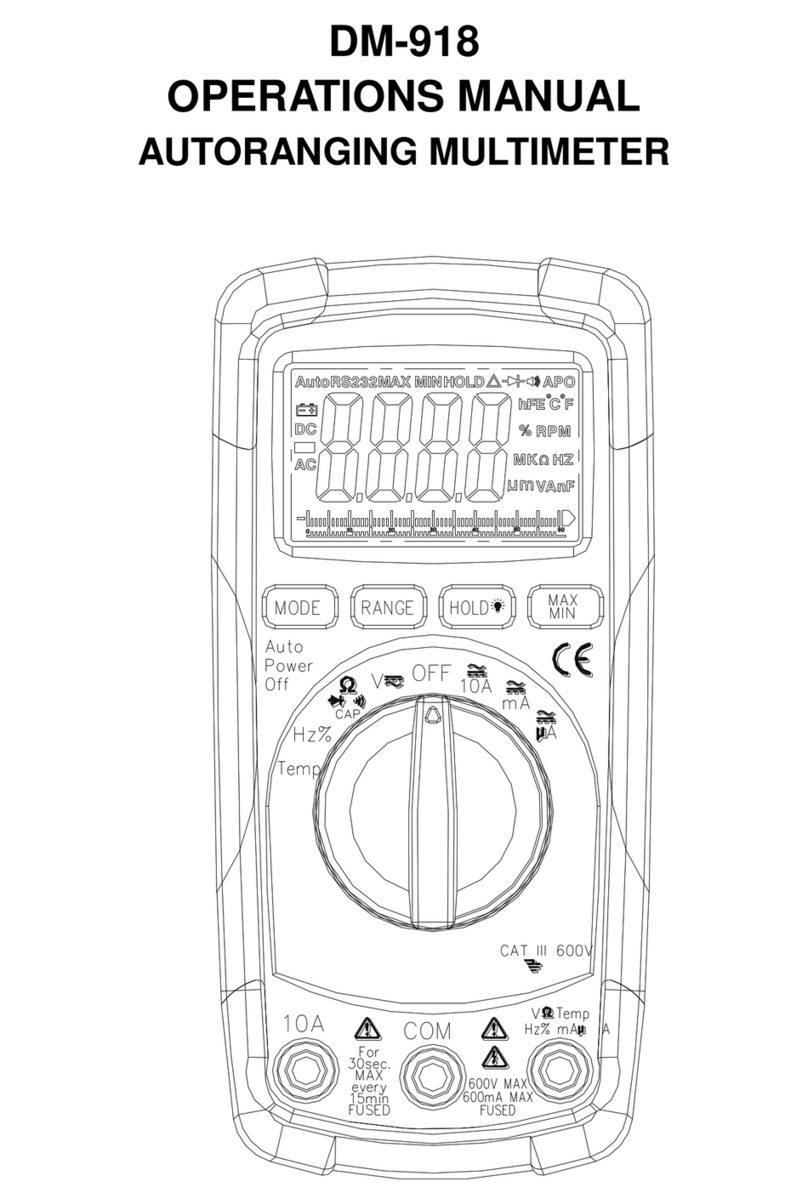

INSTRUMENT LAYOUT

1

VQHzCx* Volt, Ohms, Frequency, Capacitance,

Diode, InputTerminal

I

This is the positive input terminal for all functions except current

I

measurements. Connection is made to it using the Red test lead.

1

2

COM Common Terminal

This is the negative (ground) input terminal for all measurement

modes. Connection is made to it using the Black test lead.

3

mA

Millianlp Input Terniinal

11

This is the positive input terminal for current measurement (ac or

I

12

dc) up to

400

mA. Connection is made to it using the Red test lead.

13

4

20A

20

Amperes Input Terminal

10

This is the positive input terminal for current measurement (ac

or

dc) up to

20A.

Connection is made to it using the Red test lead.

I

'

5

Function

I

RangeSelector Rotary Switch

This rotary switch selects function and range needed. Each time the

5

rotary switch is ~iiovedfrom

OFF

to

a

function setting, all LCD

~

segments will turn on for one second.

6

PWR-RST Button

When the meter is automatic power-off, press the button to turns

meter back on.

Note: Disable Aulomntic Power-off

Ifyoupress and hold down the (PWR-RST) button whileturningthe

meterfrom

OFF

toonand selecta function,

theautomatic power-off

feature is disabled.

7

RESET Button

Press (RESET) button to erase the stored reading, and all LCD

segments will turn on for one second.

8

MEM Button

When (MEM) button is pressed, the "MEMO annunciator is dis-

played and thelast reading isstored onthe meter. If themeterpower

downautonnaticallyand thepowerback onby pressing (PWR-RST)

button, these stored readings will remain in memory.

9

READ

Button

Press (READ) button to recall thedata you stored in memory, the

readings will bedisplayed on the LCD, the "HOLD" annunciator

turnson, and the "MEM"annt~nciatorwillbedisplayedwitha blink.

Theautomatic power-off feature is disabled. Press (HOLD)button

to exit the READ mode.

10

REL

A

Button

Press (REL) button to enter the Relative mode, the "RELA

"

annunciator turns on, zero the display, and store the displayed

readindg asa reference value. Press and hold downthe(REL)button

for

2

seconds to exit the relative mode.

In the Relative

node,

the value shown on the LCD is always the

difference between the stored reference value and the present

reading. For example,

if

the reference value is 24.00V and the

present reading is 12.50V,the display will indicate -1 1.50V. If the

new reading is the same as the reference value, the display will be

zero.

11

MIN

I

MAX Button

Press(MIN

/

MAX)button toentertheMINMAXRecordingmode.

Theminimum, ~naxirnumvalues arethen reset to the present input,

the readings are stored in memory, and the "HOLD"annunciator

turns on. Push the.button to cycle through the minimum (MIN),

maxirnum (MAX), and present readings. The MIN or MAX

annunciator turns on to indicate what value is being displayed.

In the MIN MAX Recording mode, press (HOLD) button to stop

the recording of readings, press again to restart recording. If

recording is stopped, the minimum, maximum, or present values

and analog display are frozen. In the MIN MAX Recording mode,

when a new tnini~numvalue is exceed theactual minimum readings

ora new maxitnuln value is overload, the minimum ormaximum

value

willheld onthedisplay,but theanalogdisplaycontinuestobe

active.

12

HOLD

Button

Press (HOLD)button to toggle in ant1 out of the Data Hold mode,

except if you are already in the MIN MAX Recording mode.

In the Data Hold mode, the "HOLE" annunciator is displayed and

the last reading is held on the display, the beeper emits a tone, and

theauto~naticpower-off featureisdisabled. Pressing(MIN

/

MAX)

button when you are in the Data Hold modecausesyou to exit Data

Hold and enter the MIN MAX Recording mode.

13

RANGE

Button

Press (RANGE) button to select the Manual Range mode and turn

offthe "AUTO"annunciator. (Themeter remains in therangeit was

in when manltal ranging was selected).

In the Manual Range mode, each timeyou press (RANGE) button,

the range (and the input range annunciator) increments, and a new

value is displayed. To exit the Manual Range mode and return to

autoranging, press and hold down (RANGE) button for

2

seconds.

The "AUTO" annunciator turns back on.

14

Temperature.Jack

Thetemperaturejack is located in the lower left-hand cornerofthe

front panel.

To

measure a wide range of temperature

(-30°C

to

+

1300°C), plug in

a

K-type thermocouple and take the reading

direct from the digital display.

HOW

TO

MAKE MEASUREMENTS

Before making any measurements always examine the instrument

and accessories used with the instrument fordamage,contamination

(excessive dirt, grease, ect.) and defects. Examinethe test leads for

cracked orfrayed insulation and make surethe lead plugs fit snugly

into the instrument jacks. If any abnormal conditions exist do not

attempt to make any measurements.

VOLTAGE MEASUREMENTS

1.

Insert the black and red test leads into the COM and V-0 input

terminals respectively.

2. Select the desired AC voltage range

(

V-),( mV-) orDC voltage

range

(

V

--

).

WARNING

To avoid possible electric shock, instrument damage and

1

or

equipmentdamage, donot attempt totake anyvoltagemeasurements

if the voltageisabove IOOOVdc

/

750Vac. 1OOOVdcand 750Vacare

the maximum voltages that this instrument is designed to measure.

The "COM"terniinal potential should not exceed 500Vmeasuredto

ground.

3. Connect the test lead tips in parallel with the circuit to be measured

(e.g. across a load or power supply). Be careful not to touch any

energised conductors. Note the reading.

4.When all measurements arecompleted,disconnect the test leadsfrom

the circuit i~ndcrtest. Remove test leads from the multimeter.

For DC voltage readings, the RED lead tip should be connected to

thepositivesitleofthecircuit, the BLACK lead tothe negativeside.

A minus sign on the left hand sideof the LCD will appear if theleads

are connected thc other way round.

CURRENT MEASUREMENTS

These are made in series with the test circuit. All the current to be

measured flows through the multimeter.

WARNING

Donot attempt to measure currents in high energycircuitscapable

of delivering greater than 600V. Since the fuse is rated at 600V

damageorinjury could occur. The20A input terminal is protected

by a20Al600V high energy,fastblow fuse. The

mA

input terminal

is protected by a 500mAl600V fast blow fuse.

Do not exceed the limits of each current input terminal. This is 20A

(maximum time limit of 30seconds for currents greater than 10A) for

the 20A terminal and 400mA for the mA terminal.

All current ranges are fused. If a current greater than 20A on the 20A

rangeorgreaterthan500mA on all otherranges flows, thefusewill blow

causing an open circuit between the current measuring terminals.

1.

Insert the BLACK test lead in the COM input terminal.

2. Formeasuring currents lessthan 4001nA,connectthe

RED

test lead

to the mA input terminal. For measuring currents between 400mA

and 20A connect the RED test lead to the 20A terminal.

3. Select the desired AC current range (A-

)

or DC current range

(A=).

r

NOTE:

If the20A range is selected then the 20A input terminal must

beselected in step2. If the4mA, 40mA or400mA range is selected

the mA input terminal must be selected in step 2.

a

4. Switch OFFordisconnect the circuit to bemeasured from all power

sources,connect themultimeter in serieswith theconductorin which

the current to be measured flows.

5.

Switch ON the circuit. Note the reading.

6. Switch OFFor disconnect the circuit and remove the test leads from

multimeter.

CAUTION

A

common abuse of multimeters is to attempt to measure a voltage

whilethe test leadsarestill plugged into thecurrent input terminals.

This basically puts a short circuit across the voltage source since

current ranges have a low impedance. If the voltage source is

typically 240VACora 3-phaseindustrial voltage (415V),very high

fault currents can result. This is why all current input terminal are

fused. If the fusesblow they must only be replaced by theequivalent

ones otherwise the safety of the instrument may be impaired.

7.

Never apply a voltage between the COM terminal and current

terminals.

8.

When switching between current ranges to obtain greater accuracy

and better resolution, cornpletely de-energise the circuit to be

measured before changing the range.

RESISTANCE MEASUREMENTS

Turnoffpoweron the test circuitanddischargeall capacitorsbefore

attempting in-circuit resistance measurements. If an external volt-

ageis present across a component, it will be impossible to take an

1. Insert the BLACK and RED test leads into the COM and VRinput

terminals respectively.

2. Set the rotary selector switch to the (R)position.

3. Connect the BLACK and REDtest probetips to the circuit ordevice

under test, making sure

it

is de-energised first.

4. The resistance in the test leads can diminish accuracy onthe lowest

(4000) range. The error is usually 0.1 to 0.2R for a standard pair

oftest leads.Todeterminetheerror, shortthe test leadstogetherand

then use the (REL) Relative mode to automatically subtractthe lead

resistance from resistance measurements.

CONTINUITY TESTING

1.

Select the

(

I()))

)

position by turning the rotary selector switch.

2. Follow steps

1

and 3 as for resistance measurements.

An audible tone will sound for resistance less than approximately

40R.Afterall measurements arecompleted, disconnect thetest leads

from the circuit and from the multimeter input terminals.

DIODE TESTING

I

CAUTION

Measurements must only be made with the circuit power OFF.

1. Set the rotary selector switch to the

(U)

position.

2.

Follow steps

I

and 3 as for resistance measurements.

3.

TheREDlead should be connected totheanodeandtheBLACK lead

tothecathode. Forasilicondiode,thetypical forward voltageshould

be about 0.6V.

4.

If the diode is reverse biased or there is an open circuit the reading

displayed will be between 2.600V and 3.200V.

FREQUENCY MEASUREMENTS

1.

Set the rotary selector switch to the (Hz) position.

2. Insert the BLACK and RED test leads into the "COM" and "VR"

input terminals respectively.

1

3.

Apply the test prods to the points across which the frequency is to

I

be measured, and read the result directly from the display.

NOTE:

For frequencies below lOOHz and greater than 100KHz, the

display may not bestable. Forfrequenciesbelow IHz, thedisplay shows

00.00Hz.

CAPACITANCE MEASUREMENTS

Turn off power and discharge the capacitor before attempting a

capacitance measurement. Use the

DCV

function to confirm that

1.

Set the rotary sclector switch to the (Cx) position.

2.

Insert the BLACK and

RED

test leads into the

"COM"

and

"VQ"

input terminals respectively.

3.

Connect the test probe tips to the circuit ordevice under test. Note

the reading displayed.

4.

The measurement accuracy of capacitors can be improved by first

using the

"REL"

(Relative mode) to zero the display and automati-

cally subtract the residul meter and test lead capacitance. Sincethe

Relative mode also selects manual ranging,

5.

Residual voltage charges on the capacitor, orcapacitors with poor

insulation resistance or poor dielectric absorption may cause meas-

urement errors.

TEMPERATURE RiIEASUREMENTS

1.

Select the required telnperature range and unit of measurement

(OC

or

OF)

by turning the rotary selector dial to one of the "TEMP"

positions.

2.

Connect a type

K

thermocouple to the thermocouple input terminal

(yellow terminal) on the left hand sideof the front panel.

3.

Placethe Uicrmocouplejunction tipat thepoint wherethetemperature

is to be measured.

NOTE:

for very high temperatures the multimeter must be kept far

enough away fro111the source of temperature to avoid heat damage.

At high temperatures, the life of the temperature probe will be

reduced.

INPUT

WARNING

BEEPER

TheInput Warning Beeper is a feature to protect the meter and you

from i~nintelitionalmisuse. If the

DMM

is set to measure a voltage

while thetest leadsareplugged intoacurrentjack,veryhighcurrent

could result when thetest lead tipsareplaced tothevoltagetest point.

This feature warns you that the test lead needs to be changed from

a current jack to the voltage jack.

C

All current rangesarefused with fastacting ceramicfusesasanadded

protection.

SPECIFICATIONS

l

Display: 3%digit(4000 counts), 9999 counts(Frequency mode),42

segments analog bar graph and function/units sign annunciators.

Polarity: Automatic,

(-)

negative polarity indication.

Overrange Indication: MSD (Most Significant Digit) blinks.

Measurement Rate: 2/sec,nominal.

I

/set,

CapacitanceandFrequen-

'

cy mode. 20/sec, Analog Display.

l

Operating Environment: 0°Cto 50°C at

<

70% R.H.

*

StorageEnvironment: -20°C to 60°C at

<

80% R.H.

l

Temperature Coefficient: 0.1 x (specified accuracy)

/

"C

(<

18°C

or >2S°C).

l

Auto Power off: 30 minutes after rotary switch or mode changes.

Battery: Single 9Volt battery, NEDA 1604,IEC 6F22, JIS 006P.

l

Battery Life: 500hours typical with alkaline battery.

Size

(IIxWxL): 1.5 in x3.4 in x 7.5in (37 mmx87mm x 189mm).

With holster 2 in

x

3.8 in x 7.9 in (52 mm

x

96 mm

x

200mm).

l

Weight: Approx. 320g. With holster 435g.

*

Accuracy is given as

f

([%

of reading]+[number of least significant

digits]) at 18°Cto 28"C, with relative humidity up to 70%.

DC

Volts

AC

Volts

(Average sensing RMS indicating)

Range

400mV

4v

Input Impedance

>

1000MR

1IMR

1OMR

1OMR

1OMR

Range

400mV

4V

40V

400V

IOOOV

*

The frequency response for 400mV range are 50Hz to 100Hz only

Input Impedance: Sanie as DCV function with less than lOOpF

Overload Protection: 1000VDCor 750VAC rms

Resolution

IOOpV

I

rnV

1

OmV

lOOlnV

1

V

Resolution

IOOpV

I

mV

l

01nV

100mV

1V

DC Current

Accuracy

-t-(0.1% rdg+2d)

f

(0.1

%

rdg +2d)

+(0.1% rdg+2d)

f

(0.1

%

rdg+2d)

*(O.

I

%

rdg+2d)

Accuracy(5OHzto 500Hz) (500Hz to IKHz)

Overload Protection: 500mA/600V fuse on mA inputs (fast blow

ceramic fuse). 20Al600V fuseon 20A inputs(fast blow ceramic fuse).

**IOA continuous, 20A for 30seconds maximum.

*

*(0.8% rdgf5d)

+(0.5%rdg+3d)

*(0.5% rdg+3d)

*(0.5% rdg+3d)

+(0.5% rdg+3d)

Accuracy

+(0.8% rdgf2d)

+(O.S% rdg+2d)

f

(1.2%rdg+4d)

AC Current

(Average sensing RMS indicating)

Unspecified

*(1.2%rdg+Sd)

k(1.O% rdg+5d)

&(I.O% rdg+5d)

*(I .2%rdg+5d)

Burden Voltage

450mV

450mV

650mV

650mV

Overload

Protection:

1000VDCor 750VAC rms

Range

41nA

40mA

400mA

20A**

Overload Protection: 500niA/600V fuse on mA inputs (fast blow

ceramic fuse). 20Al600V fi~seon 20A inputs(fast blow ceramic fuse).

**IOA continrlous,20A for 30seconds maximum.

Resolution

PA

10pA

IOOpA

IOmA

Accuracy (5OHz

to

IKHz)

-

+(I

.Z%

rdg +4d)

*(I .2% rdg+4d)

+(I .2% rdg+4d)

*(I .5%rdg+5d)

Burden Voltage

450mV

450mV

650mV

650mV

Resistance Frequency

Range

400R

4KR

40KQ

400KR

4000KQ

40MR

Resolution

0.1R

1

R

lOR

IOOR

IKR

IOKR

Range

l00Hz

lKHz

IOKHz

l00KHz

400KHz

Diode Test

Overload Protection: 500V DC or RMS AC Overload protection: 5OOVDC or RMS AC

,

NOTE:

For frequencies below IOOHz and greater than IOOKHz, the

display may not bestable. Forfrequenciesbelow 1Hz, thedisplay shows

Continuity

Test

00.00~~.

Accuracy

*(0.5% rdgf4d)

f

(0.4% rdgf2d)

f

(0.4% rdg+2d)

+(0.4% rdg+2d)

+(0.7% rdgf4d)

f

(I

.2%

rdg+4d)

Resolution

0.01H.z

0.1H.z

1Hz

lOHz

1

OOHz

Overload Protection: 500V DC or RMS AC Overload Protection: 60VDC or 24VAC rms

Open Circuit Volts

O.4Vdc

0.4Vdc

0.4Vdc

0.4Vdc

0.4Vdc

0.4Vdc

Open Circuit Volts

0.4Vdc

Range

400R

Sensor

type

K-type

1300°C

2372°F

f

(1.0% rdg+4"F)

Accuracy

+(O.l% rdg+IOd)

f(O.l% rdgf4d)

+(0.1% rdgf4d)

+(0.1% rdgf8d)

$.

(0.1

%

rdg

+20d)

Temperature

Overload Protection: 500V DC or RMS AC

Range

4V

Capacitance

Trigger Level

40mV

40 mV

40 mV

400 mV

400 mV

Audible Threshold

Less than 40R

Accuracy

f(1

.O%

rdg+

ld)

Resolution

l~nV

Response Time

Approx. 100ms

Overload Protection: 500V DC or RMS AC

16

Test Current

0.61nA Open Circuit Volts

3.2Vdc typical

Accuracy

(With

film

capacitor

or

better)

f(2.0% rdgf20d) in Relative mode

*(2.0% rdg+4d) in Relative mode

+(2.0% rdg+4d)

+(2.0% rdg+4d)

f

(2.0%rdg+4d) at

<

20

pF

f

(5.0% rdg+4d) at

>

20pF

Range

4 nF

40 nF

400 nF

4 pF

40

pF

Resolution

0.001 nF

0.01 nF

0.1 nF

0.001 pF

0.01 pF

MAINTENANCE

REPLACING

THE

FUSE

Repairs or servicing not covered in this manual should only be

performed by qualified personnel.

REPLACING

THE BATTERY

WARNING

TOAVOID ELECTRICAL SHOCK, DISCONNECT THETEST

LEADS AND ANY INPUT SIGNALS BEFORE REPLACING

THE BATTERY. REPLACE ONLY WITH SAME TYPE

OF

BATTERY.

WARNING

TO

AVOID

ELECTRICAL

SHOCK,

DISCONNECT

THE

TEST

LEADS AND ANY INPUT SIGNALS BEFORE REPLACING

THEFUSES. REPLACE ONLY WITH SAMETYPEOFFUSES.

THE20A INPUTTERMINALISPROTECTEDBYA F20A,600V

HIGH ENERGY, FAST ACTING. THE mA INPUT TERMINAL

IS PROTECTED BY A F500mA,600V FAST ACTING FUSE.

-

Use the following procedure to examine or replace the meter's fuses:

1.

Disconnect test leads from any live source,turn the rotary switch to

This meter is powered by a NEDA type

1604

or equivalent 9-volt OFF, and remove the test leads from the input terminals.

battery.

When the multi~neterdisplays the

"

El

"

the battery must be replaced

2.

The case bottom is secured to the case top by three screws and two

to maintain proper operation. Use the following procedureto replacing internal snaps(at the LCD end). Using aPhillips-head screwdriver,

the battery: removethethreescrewsfrom thecasebottom and turn thecaseover.

1. Disconnect test leads from any livesource,turn the rotary switch to

3.

Lift the input terminal end of the case bottom until itgently unsnaps

OFF, and reliiove the test leads from the input terminals. from the case top at the end nearest the LCD.

2. The case bottom is secured to the case top by three screws and two

4.

Remove blown fuse, replace with fuse of the samesizeand rating.

internal snaps(at the LCDend). Using a Phillips-head screwdriver, Make sure the new fuse is centered in the fuseholder.

remove thethreescrewsfrom thecasebottom and turn thecaseover.

,

5.

Replace the case bottom, ensuring that the two snapson thecasetop

3.

Lift the input terminal end of the case bottom until it gently unsnaps (at the end near the LCD) are engaged. Reinstall the three screws.

from the case top at the end nearest the LCD.

4.

Re~iiovebattery and replace with a new equivalent 9-volt battery.

5.

Replace the case bottom, ensuring that the two snapson thecasetop

(at the end near the LCD) are engaged. Reinstall the three screws.

PIN

7000-1330

March

1994

Table of contents

Other PDi Multimeter manuals

Popular Multimeter manuals by other brands

Elma Instruments

Elma Instruments Auto-Check Series user manual

Mastech

Mastech MS8221 user manual

Simpson

Simpson 260 Series 5P Operator's manual

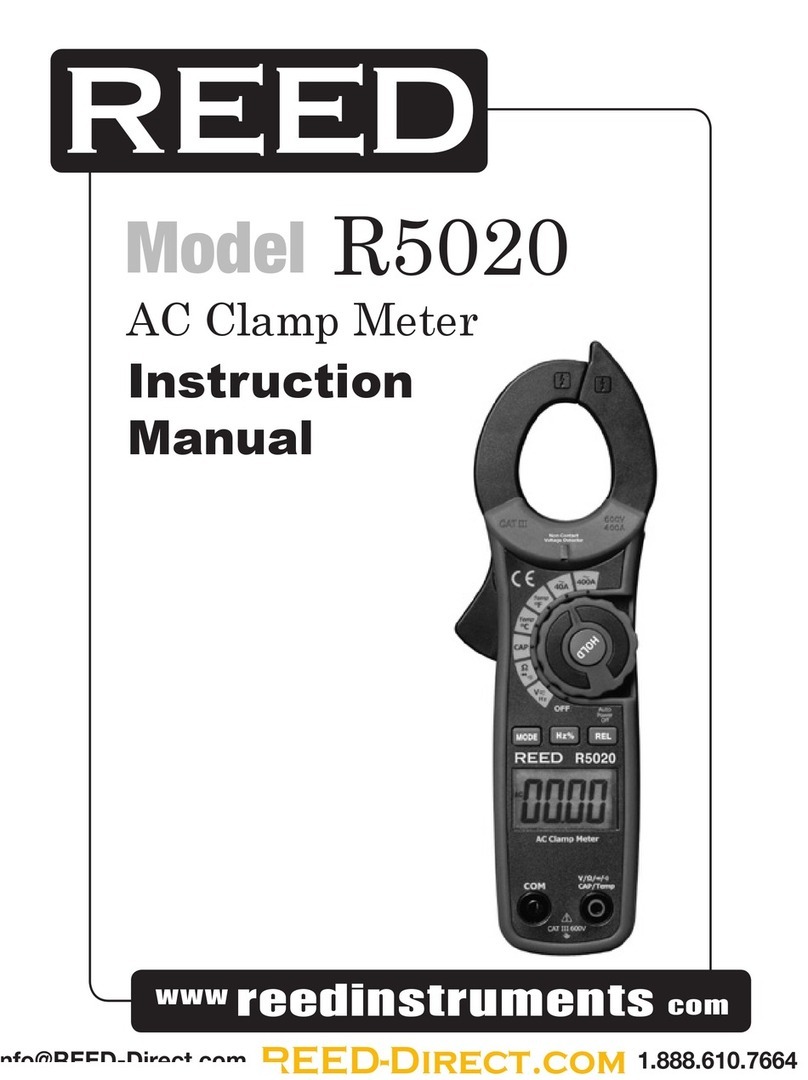

REED

REED R5020 instruction manual

A.W. Sperry Instruments

A.W. Sperry Instruments DM-2A POCKET-PRO operating instructions

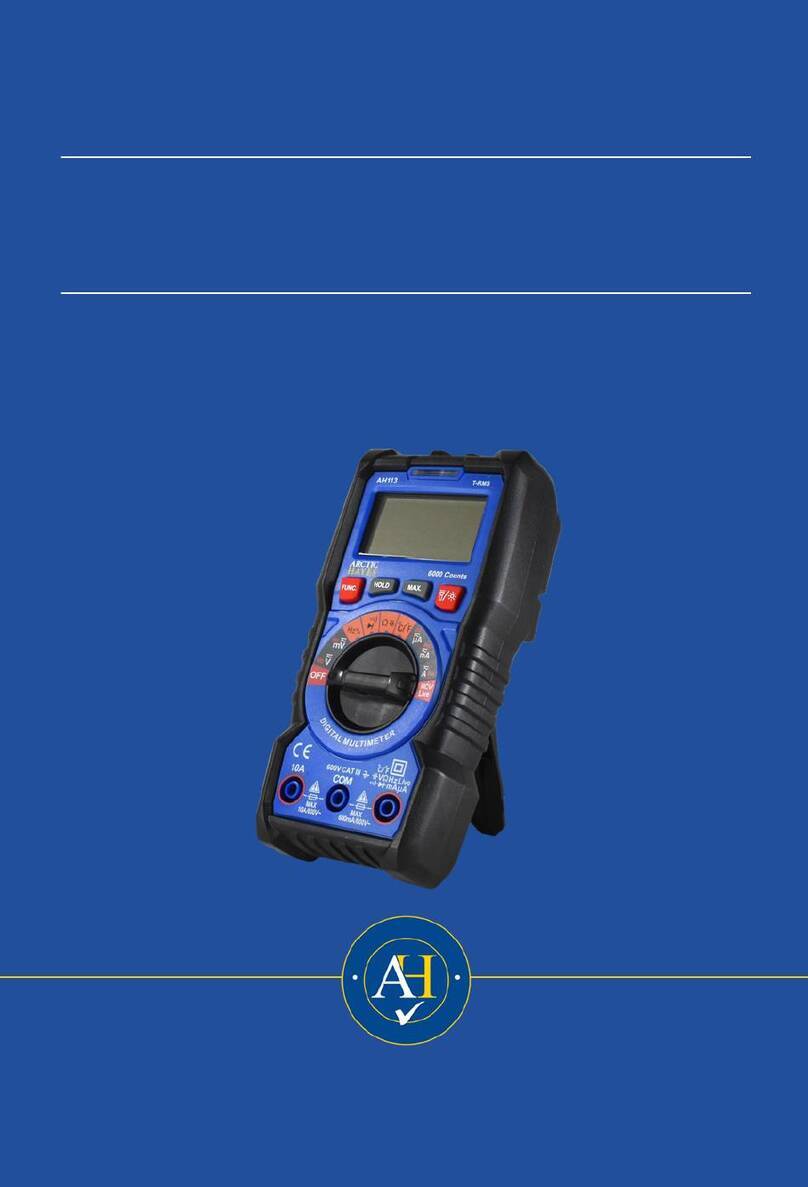

ARCTIC HAYES

ARCTIC HAYES AH113 user manual