PDi 879RMS User manual

OPERATING INSTRUCTIONS

Model

879RMS

DIGITAL

MULTIMETER

CONTENTS

HOW TO

MAKE MEASUREMENTS

..................................

&

voltage Measurements

8

CurrentMeasurements

9

ResistanceMeasurements 11

Continuity

the ti^^

I1

DiodeTesting 11

LogicTesting 11

Frequency and DutyCycleMeasurements 12

INTRODUCTION

Thismanualcontainsinformationand warningswhich mustbe followed

to ensure safe operation and retain the meter in safe condition.

WARNING

READ "SAFETY INFORMATION" BEFORE USING THE METER.

Thismultimeter isahandheld, 20000-count instrument that isdesigned

for use in the laboratory, field servicing, and at home. This meter

featurescompactdesignwith roundedcorners foreasyhandling and has

arugged case in shock resistant and fire-retardant. Electronicoverload

protection forall functionsand ranges. TheProtective Holster (optional

accessory) combined with rugged case make it a durable and reliable

instrument.

UNPACKING

AND

INSPECTION

Upon removingyournew Digital Multimeter(DMM) from itspacking,

you should have the following items:

1. Digital Multimeter

I

2.

Test Lead Set (one black, one red)

3.

9-Volt Battery (installed in meter)

i

4.

Instruction Manual

5.

One SpareFuse (500mA/600V, 6.3mm

x

25mm, fast acting)

If any of the above items are missing or are received in a damaged

cond~tion,pleasecontact thedistributor from whom you purchased the

unit.

SAFETY INFORMATION

Injury or death can occur even with low voltages and low currents. It

is extremely important that you read these safety information before

usingyourmultimeter. Followall safety practicesand properoperating

procedures for equipment being tested.

I. Exercise extreme caution when:

Measuring voltage above 20 volts, measuring current greater

than

IOmA, measuring AC power line with inductive loads, measuring

AC power line during electrical storms.

2.

Always inspect your DMM, test leads and accessories for

any

sign

of damage or abnormality before every use. If any abnormal

conditions exist (i.e., broken ordamaged test leads, cracked case,

display not reading, etc.),donot attempt to takeany measurements.

3.

Never ground yourselfwhen taking electrical measurements. Donot

touch exposed metal pipes, outlets, fixtures, etc., which might beat

groundpotential. Keepyourbody isolated from groundbyusing dry

clothing, rubber shoes, rubber mats, or any approved insulating

material.

4.

Never touch exposed wiring, connections,testprobetips, orany live

circuit conductors when attempting to make measurements.

5. Never replace the protective fuse insidethe DMM with a fuseother

than the specified or approved equal fuse.

6.

Do not operate this instrument in an explosive atmosphere (i.e., in

the presence of flammable gases or fumes, vapor or dust.)

7.

Measuring voltage which exceeds the limits

of

the multimetermay

damagethe meter and exposetheoperatortoashockhazard. Always

recognizethemeter voltage limits asstated onthefrontofthe meter.

8.

Never apply more than 5OOVDC between the COMjack and earth

ground.

9.

Never touch a voltage source when the test leads are plugged into

a current jack.

10. When testing for the presenceof voltage orcurrent, make surethe

voltage orcurrent ranges arefunctioningcorrectly. Takea reading

of a known voltage or current before assuming a zero reading

indicates no current or voltage.

SYMBOL

EXPLANATION

1-

-

-

-

,

,

,

l(1))

A

Attention! Refer to the Operating Instructions

Dangerous Voltage May Be Present at terminals

Ground

AC

-

Alternating Current

DC

-

Direct Current

Audible Continuity

/

Diode

Logic Test

Double Insulation

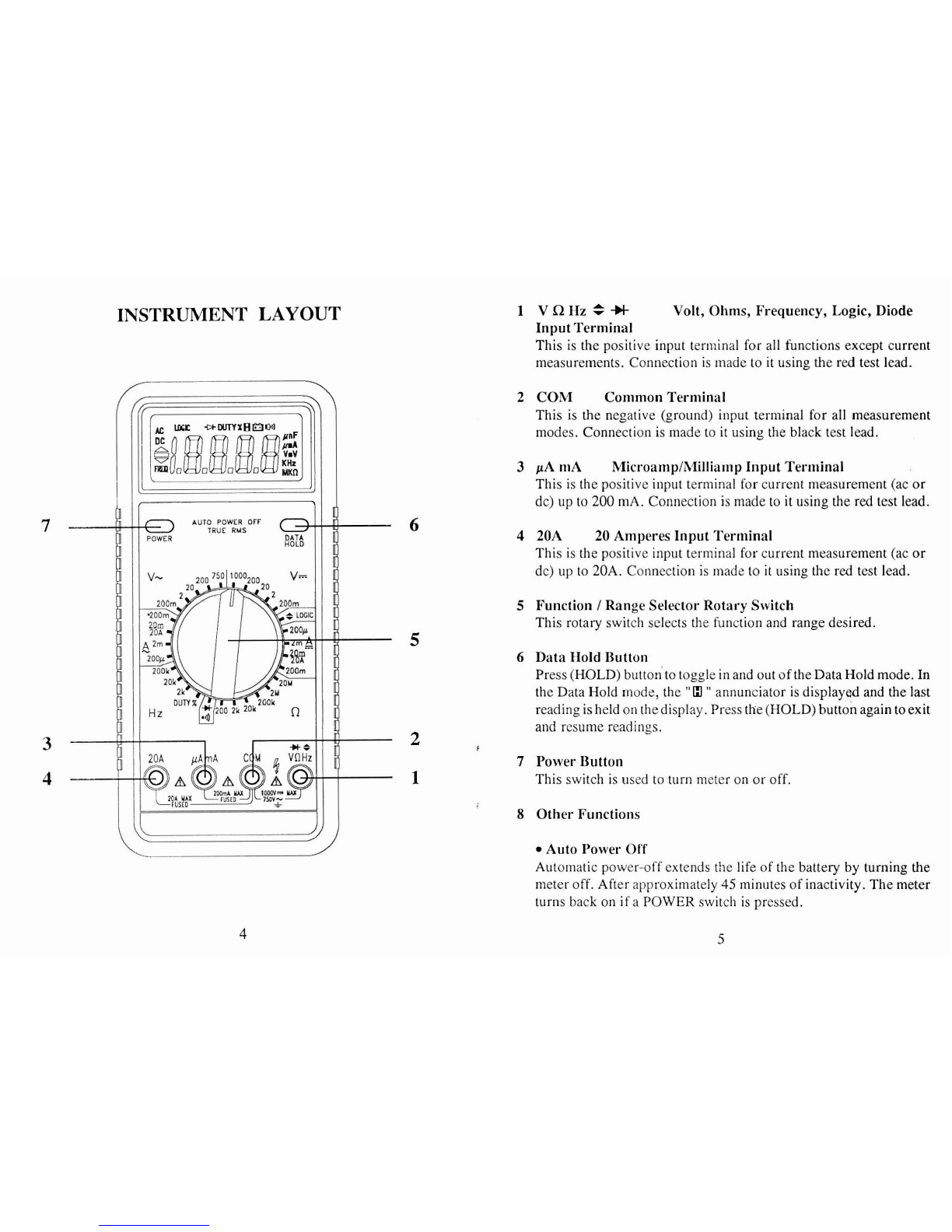

INSTRUMENT

LAYOUT

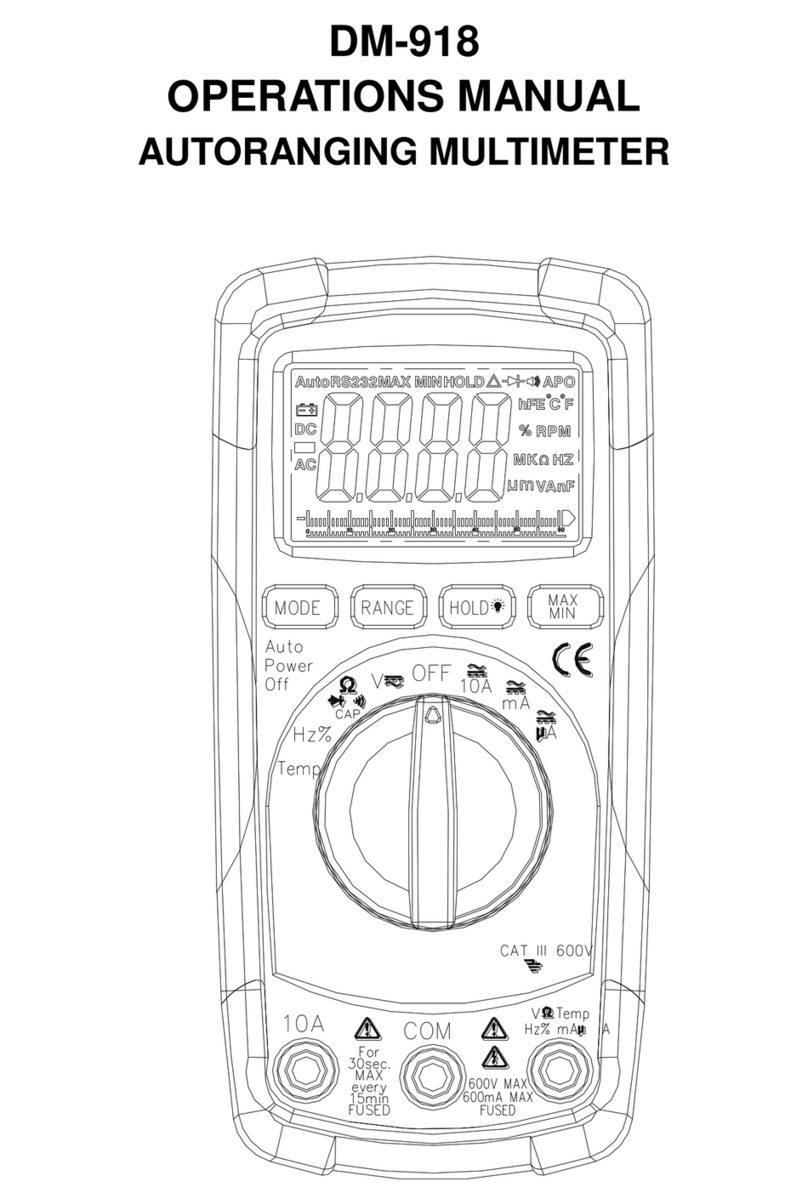

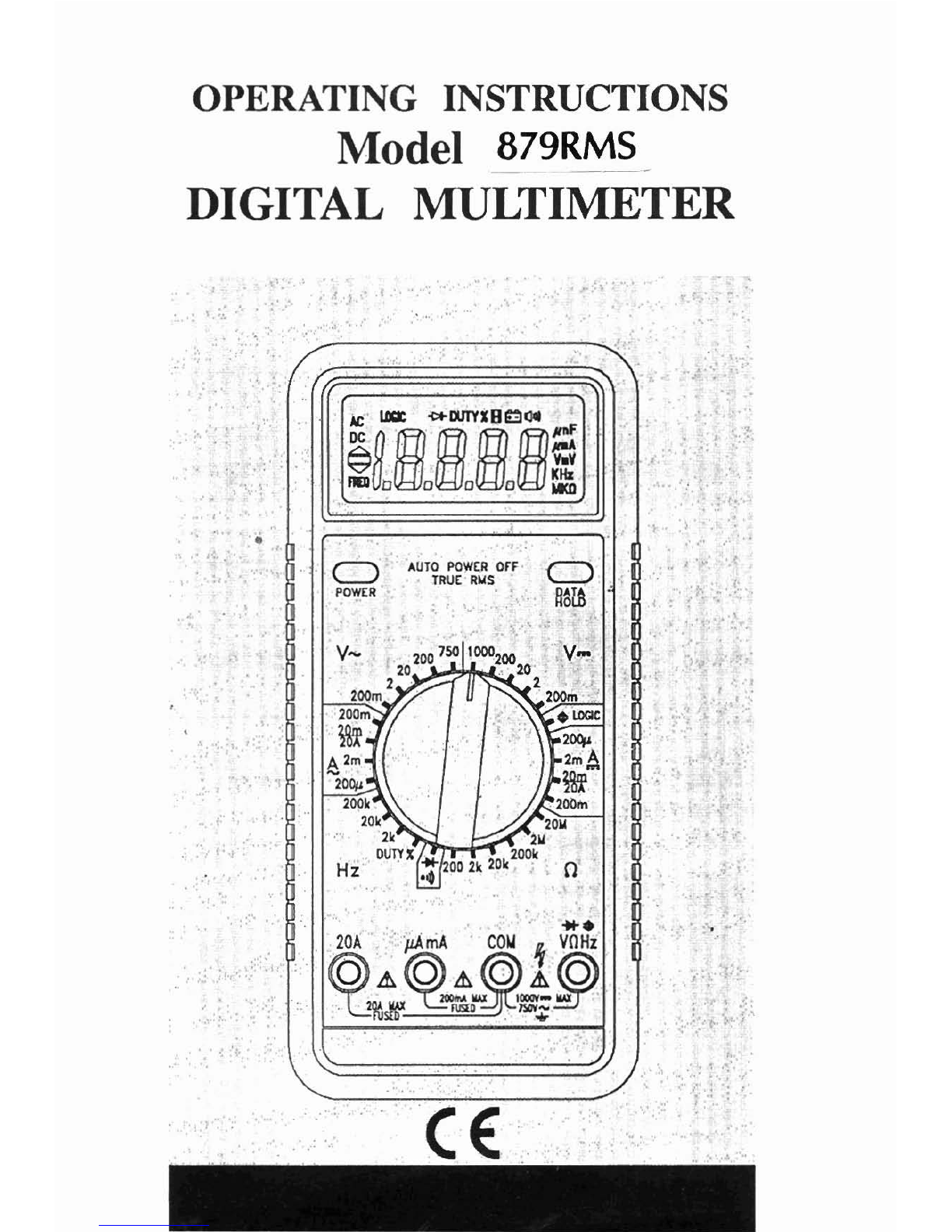

1 VQHz=-H

Volt, Ohms, Frequency, Logic, Diode

InputTerminal

This is the positive input terminal for all functions except current

measurements. Connection is made to it using the red test lead.

2

COM Common Terminal

This is the negative (ground) input terminal for all measurement

modes. Connection is made to it using the black test lead.

3

pA niA MicroamplMilliamp Input Terminal

This is the positive input terminal for current measurement (ac or

dc) up to

200

mA. Connection is made to it using the red test lead.

6

4

20A

20

Amperes Input Terminal

This is the positive input terminal for current measurement (ac

or

dc) up to 20A. Connection is made to it using the red test lead.

5

Function

I

Range Selector Rotary Switch

This rotary switch selects the function and range desired.

5

6

Data Hold Button

Press (HOLD)buttonto toggle in and out of the Data Hold mode. In

the Data Hold mode, the

"

13

"

annunciator is displayed and the last

readingisheld on thedisplay. Press the (HOLD) button again toexit

and resume readings.

3

A

I

7

Power Button

1

This switch is used to turn meter on or off.

8

Other Functions

Auto Power Off

Automatic power-off extends the life of the battery by turning the

meter off. After approximately

45

minutes of inactivity. Themeter

turns back on if a POWER switch is pressed.

Input Warning Beeper

The Input Warning Beeper is a feature to protect the meter and you

from unintentional misuse. If the DMM is set to measure a voltage

whilethe test leadsareplugged into acurrentjack, very high current

could resultwhen thetest lead tips areplaced tothevoltagetest point.

This feature warns you that the test lead needs to be changed from

a currentjack to the voltage jack.

All currentranges arefusedwith fastacting ceramicfuses

as

an

added

protection.

TrueRMS Measurements

This multimeter permits direct measurement of the true RMS value

of a signal. This is the best way to measure parameters used for

measuremen!s relating to power.

The relationship between the total true RMS (AC

+

DC) and

the

componentAC and DC signals is givenby thefollowingexpression:

True RMS

=

d

(AC RMS Comp~nent)~

+

(DC Comp~nent)~

RMS

is

equivalent tothatDC valuewhichdissipates thesameamount

of power in a resistor asthe original signal and can be visualized by

the relationships

Power

=

"Average-responding" meters provide accurate RMS readings for

sinusoidal signals,but can introducesignificant errorswhen measur-

ing nonsinusoidal waveforms. Thefollowing tableshowstheerrors

that result when the average-respondingmeasurement isused instead

of the True RMS value.

Thisnii~ltimeteris ACCorlpledand will accurately measuretheAC RMS

component ofan inputsignal. TheDC voltage function willmeasurethe

DC component. Toobtain the total true RMS value, measure theRMS

AC component on the AC function and the DC component on the DC

function. Then,calculate the TrueRMS value, using the measured AC

and DC components and the True RMS expression given above.

Power Calculations (watts) from Voltage Measurements

(Vpk

=

IOOV, Load

=

1

kRresistor)

AC converters of all types are limited by their frequency response and

input dynamicrange. Measurementsof complex waveforms will notbe

affected by converterbandwidth limitations, provide that all significant

AC components contained within the waveforms are within the band-

width of the converter.

Crest factor isameasure of the input dynamicrangeofanACconverter.

It expresses the ability of the converter to accept a signal that has large

peak values compared to itsRMS valuewithout saturating theconverter

circuitry and degrading the specified accuracy. Crest factor is defined

as the ratio of the peak voltage to the total AC RMS voltage.

Sinewave

Square wave

Triangle wave

Crest Factor

=

V(PEAK)

V(AC RMS)

AC RMS

average

responding

5.0

12.3

3.1

--

AC

True RMS

5.0

10.0

3.3

Error

0%

+23

%

-6

%

HOW

TO'

MAKE

MEASUREMENTS

Before making any measurements always examine the instrument

and accessoriesused with theinstrumentfordamage, contamination

(excessivedirt,grease, ect.) and defects. Examine the test leads for

cracked orfrayed insulation and make surethe lead plugs fit snugly

into the instrumentjacks. If any abnormal conditions exist do not

attempt to make any measurements.

VOLTAGE RlEASUREMENTS

1. Insert the black and red test leads into the COM and V-R input

terminals respectively.

2. Select the desired AC voltage range (V-

),

or DC voltage range

(V-).

WARNING

To avoid possible electric shock, instrument damage and

/

or

equipment damage,donot attempt totakeany voltagemeasurements

if the voltageis above

1

OOOVdc

/

750Vac. lOOOVdc

and

750Vacare

the maximum voltages that this instrument is designed to measure.

The"COM"terminal potential shouldnot,exceed500Vmeasured to

ground.

A

3.

Connect thetest lead tips in parallel with the circuit to bemeasured

(e.g. across a load or power supply). Be careful not to touch any

energised conductors. Note the reading.

4.

When allmeasurements arecompleted, disconnectthe test leadsfrom

the circuit under test. Remove test leads from the multimeter.

For

DC

voltage readings, the RED lead tip should beconnected to

the positiveside of thecircuit, the BLACK leadto thenegativeside.

A minussign on the left hand sideof theLCDwill appear if theleads

areconnected the other way round.

CURRENT MEASUREMENTS

These are made in series with the test circuit. All the current to be

measured flows through the multimeter.

WARNING

Donot attempt to measurecurrents inhigh energy circuitscapable

of delivering greater than 600V. Since the fuse is rated at 600V

damageor injurycould occur. The20Ainput terminal isprotected

by a20AI600Vhigh energy,fastblow fuse. The

mA

input terminal

is protected by a 500mAl600V fast blow fuse.

Do not exceed the limits of each current input terminal. This is 20A

(maximum time limit of 30seconds for currents greater than 10A)for

the 20A terminal and 200mA for the mA terminal.

All current ranges are fused. If a current greater than 20A on the 20A

rangeorgreater than500mA onall otherranges flows, thefusewillblow

causing an open circuit between the current measuring terminals.

1. Insert the BLACK test lead in the COM input terminal.

2. Formeasuring currents less than 200mA, connect the REDtest lead

to the mA input terminal. For measuring currents between

200mA

and 20A connect the RED test lead to the 20A terminal.

3.

Select the desired AC current range or DC current range.

4.

Switch OFFordisconnectthe circuitto bemeasured from all power

:

sources,connect themultimeter in serieswith theconductorin which

the current to be measured flows.

5. Switch ON the circuit. Note the reading.

6. Switch OFFordisconnect the circuitand removethetest leads from

multimeter.

CAUTION

A common abuse of multimeters is to attempt to measure a voltage

while the test leads arestill plugged into the current input terminals.

This basically puts a short circuit across the voltage source since

current ranges have a low impedance. If the voltage source is

typically

240VAC

ora3-phase industrial voltage

(415V),

very high

fault currents can result. This is why all current input terminal are

fused.

If

the fusesblow they mustonly bereplaced by theequivalent

ones otherwise the safety of the instrument may be impaired.

7.

Never apply a voltage between the COM terminal and current

terminals.

8.

When switching between current ranges to obtain greater accuracy

and better resolution, completely de-energise the circuit to be

measured before changing the range.

RESISTANCE MEASUREMENTS

Turnoffpoweronthetest circuitanddischargeall capacitors before

attempting in-circuit iesistancemeasurements. If an external volt-

age is present across a component, it will be impossible to take an

1.

Insert the BLACK and RED test leads into the COM and

VQ

input

terminals respectively.

2.

Select the desired ohms

(R)

range.

3. Connectthe BLACK and RED test probe tips to the circuitordevice

under test, making sure it is de-energised first.

4.

Test lead resistance can interfere when measuring low resistance

readingsand should be subtracted from resistance measurements for

accuracy. Select lowest resistance range andmakethe testleadsshort

together.Thedisplay value is thetest lead resistancetobesubtracted.

CONTINUITY TESTING

1. Select the

(

10))

)

position by turning the rotary selector switch.

2.

Follow steps

1

and 3 as for resistance measurements.

An audible tone will sound for resistance less than approximately

150Q.

After all measurements are completed, disconnect the test

leads from the circuit and from the multimeter input terminals.

'I

I

DIODE TESTING

CAUTION

Measurements must only be made with the circuit power OFF.

1. Set the rotary selector switch to the

(*)

position.

2.

Follow steps

1

and 3 as for resistance measurements.

3.

TheRED lead should be connected totheanodeand theBLACK lead

to the cathode. The typical forward voltage drop should be about

0.7V

for silicon diode or

0.4V

for germanium diode.

4.

If the diode is reverse biased or there is an open circuit the reading

display shows

"1

".

LOGIC TESTING

1.

Insert the BLACK and RED test leads into the "COM" and

"VR"

input terminals respectively.

1

2.

Select the logic function by rotating the selector dial to the

(

*

)

logic position.

\

3. Connect the BLACK probe tip to the Common Bus of the logic

circuitry to be measured.

4.

Connect the RED probe tip to the point to be tested.

5.

With a logichigh pulse

(I),

the

A

indicatorwilldisplay in the LCD

and a beeping sound will emit. With a logic low pulse

(O),

the

r

indicator will appear in the LCD.

FREQUENCY AND DUTY CYCLE MEASUREMENTS

SPECIFICATIONS

1.

Set the rotary selector switch to the "Hz" range desired for a Display:

4%

digits, 17mmlarge LCD maximum reading 19999with

function and unit sign annunciators.

-

measurement. Polarity: Automatic,

(-)

negative polarity indication.

2. Insert the BLACK and RED test leads into the "COM" and "VQ"

input terminals respectively. Overrange indication:

"

1

"

most significantdigit blinks.

The frequency ranges have overload protection to 500Vac/Vdc.

DO NOT EXCEED THIS LIMIT. To do so could damageyour

multimeter.

Low battery indication: The

"

El

"

is displayed when thebattery

voltage drops below the operating level.

Auto power off: Meter automatically shuts down after approx. 45

minutes of inactivity.

Measurement rate: 2.5 times per second, nominal.

Operating environment: 0°Cto 50°Cat

<

70%R.H.

Storage temperature: -20°C to 60°C, 0 to 80%R.H. with battery

3. Apply thetest leads to thepoints acrosswhich thefrequency is tobe removed from meter.

measured, and read the result directly from the display. Power: Single9V battery, NEDA 1604,JIS 006P, IEC 6F22.

4. To make duty cycle test during frequency measurements, place the Battery life: 300 hours typical with carbon-zinc.

range selectorswitch into the "DUTY

%"

position. Thedisplay will

.

Dimensions:

Sgmm

87mm

(W)

37mm

indicate 0%to 90.0% of the frequency duty cycle. Weight: Approx. 330g including battery.

*

Accuracy is given as

*([%

of reading] +[number of least significant

digits]) at 18°Cto 2S°C, with relative humidity up to 70%.

DC

Volts

Accuracy Input Impedance

200mV lOpV k(0.05

%

rdg+3d)

k(0.05

%

rdg+3d)

+(0.05

%

rdg+3d)

200V lOmV

f

(0.05%rdg+3d) 1OMR

l00OV lOOmV +(0.05% rdg+3d) lOMQ

Overload Protection: 500VDC

/

350VRMS on 200mV range

1

OOOVDC

/

750VRMS on all other ranges

AC Volts

(True RMS)

Range

I

Resolution I~ccurac~(50~zto 500~z)l500Hz to 2KHz

2OOmVI 10pV

I

+(1.0% rdg+lOd)

1

+(2.0% rdg+20d)

Input Impedance: IOMQ

Overload Protection: SOOVDC

/

350VRMS on 200mV range

IOOOVDC

/

750VRMS on all other ranges

2V

20V

200V

750V

DC Current

Range

I

F&solution

I

Accuracy

I

Voltage Burden

200pA

I

lOnA

I

&(0.5%rdg+5d)

I

300mV

100pV

1

mV

lOmV

lO01nV

Overload Protection: 500mAJ600V fuse on mA inputs (fast blow

ceramic fuse). 20A1600V fuseon 20A inputs(fast blow ceramic fuse).

**

20A for 30 seconds maximum.

*(I .O%rdg+ 10d)

+(I .O%rdg+ l0d)

-

+(1.0% rdg+ 1Od)

+(2.0%rdg+20d)

2mA

201nA

200mA

20.4

*

x

AC C~rrent

(True RMS)

+(2.0% rdg+20d)

+(2.0% rdg+20d)

+(2.0% rdg+20d)

Unspecified

+(0.8% rdg+ 10d)

1

OOnA +(0.8%rdg+10d) 300mV

*(0.8% rdgf 1Od) 300mV

&(0.8% rdg+lOd) 600mV

1mA +(2.5% rdg+ 10d) 800mV

lOOnA

I

PA

10pA

I

mA

Resistance

*(0.5% rdg+Sd)

k(0.5%rdg+5d)

k(0.5%rdg+5d)

+(2.0%rdg+ 10d)

.

Overload Protection: 500V DC or RMS AC

300mV

300mV

600mV

800mV

Continuity Test

Open Circuit Volts

=3.3Vdc

23.3Vdc

=3.3Vdc

-3.3Vdc

e3.3Vdc

=3.3Vdc

Range

200Q

2kR

20kR

200kR

2MQ

20MQ

Range l~udibleThreshold

I

Response Time

I

Open Circuit Volts

2V

(

Less than l5OR

I

Approx. 500ms

I

3.3Vdc typical

p~

Overload Protection: 500V DC or RMS AC

Diode Test

Resolution

lOmQ

0.IQ

1Q

10Q

1

OOQ

1kQ

Accuracy

+(0.25% rdgf10d)

k(0.15

%

rdg+3d)

+(0.15% rdg+3d)

+(0.15%rdg+3d)

f

(0.25%rdg+lOd)

+(I .O%rdg+10d)

Overload Protection: 500V DC or RMS AC

Logic Test

Open

Circuit Volts

3.3Vdc typical

Range

2V

Test Voltage: 5VDC

Duty Cycle: >20% and <SO%

Overload Protection: 500mAl600V fuse on mA inputs (fast blow Frequency Response: 20MHz

ceramic fuse). 20A1600V fuseon 20A inputs(fast blow ceramic fuse). Indication: 40msec beep at logic

1

(Hi)

**

20A for 30 seconds maxi~nurn. Overload Protection: 5OOVDC or RMS AC

Resolution

Pluse Width

(min.)

25nS

Thresholds

Logic

1

(Hi)

I

Logic 0 (Lo)

2.8Vf 0.8V

I

0.8V+0.5V

Accuracy

Pulse Rise

(max.)

l0,uSec

Test

Current

O.lmV

1

+(0.5%

rdg+ld)

Pulse Rep

(max.)

lMpps

l.OmA

Frequency

Accuracy Input Impedance

0.1Hz +(0.5% rdg+3d) 1OMWlOpF

+(0.5% rdg+3d) 1OMWlOpF

+(0.5% rdg+3d)

1

OMMlOpF

Sensitivity: 50mV RMS min. (Sine Wave)

400mV RMS min. at >30% and <70% duty cycle

Effect reading: More than 10Hzat pulse width >2pSec

Overload protection: 5OOVDC or RMS AC

Duty

Cycle

Frequency range: 20Hz to 20kHz

Overload protection: 5OOVDC or RMS AC

Range

0 to 90.0%

MAINTENANCE

Repairs or servicing not covered in this manual should only be

performed by qualified personnel.

Resolution

0.1

%

REPLACING

THE

BATTERY

TOAVOID ELECTRICALSHOCK, DISCONNECT THETEST

LEADS AND ANY INPUT SIGNALS BEFORE REPLACING

THE BATTERY. REPLACE ONLY

WITH

SAME TYPE OF

BATTERY.

PulseWidth

>

I

OpSec This meter is powered by a NEDA type 1604 or equivalent 9-volt

battery.

When the multimeter displays the

"

E3

"

the battery must be replaced

to maintain properoperation. Use the following procedureto replacing

the battery:

Accuracy

(5V

Logic)

,(2.0% rdg

+

10d)

1. Disconnect test leads from any live source, turn the rotary switch to

OFF,

and remove the test leads from the input terminals.

2. Thecase bottom is secured to the case top by three screws and two

internal snaps (at the LCD end). Using aPhillips-head screwdriver,

removethe threescrewsfrom thecasebottom and turn thecase over.

3.

Lift the input terminal end of thecase bottom until it gentlyunsnaps

from the case top at the end nearest the LCD.

4.

Remove battery and replace with a new equivalent 9-volt battery.

5. Replace the casebottom, ensuring that the two snaps on the casetop

(at the end near the LCD) are engaged. Reinstall the three screws.

REPLACING

THE

FUSE

NOTE

WARNING

TOAVOID ELECTRICAL SHOCK, DISCONNECT THETEST

LEADS AND ANY INPUT SIGNALS BEFORE REPLACING

THEFUSES. REPLACEONLY WITHSAMETYPEOFFUSES.

THE

20A

INPUTTERMINALISPROTECTED

BY

A

F20A,600V

HIGH ENERGY, FAST ACTING. THE mA INPUTTERMINAL

IS PROTECTED BY

A F500mA,600V

FAST ACTING FUSE.

-

Use the following procedure to examine or replace the meter's fuses:

1.

Disconnect test leads from any live source, turn the rotary switch to

OFF, and remove the test leads from the input terminals.

2.

The case bottom is secured to the case top by three screws and two

internal snaps (at the LCDend). Using aPhillips-head screwdriver,

remove thethreescrewsfrom thecasebottom and turn thecaseover.

3.

Lift the input terminal end of the case bottom until itgently unsnaps

from the case top at the end nearest the LCD.

4.

Remove blown fuse, replace with fuse of the same size and rating.

Make sure the new fuse is centered in the fuse holder.

5.

Replace the case bottom, ensuring that the two snapson the casetop

(at the end near the LCD) are engaged. Reinstall the three screws.

PIN

7000-

1328

March

1994

Table of contents

Other PDi Multimeter manuals