– 10 –

• Do not attempt to cut pieces too small to

safely hold down on the main table.

• Never use the side of the blade to cut or

grind with, only cut in a straight line.

• Keep all parts of your body away from the

blade and all other moving parts.

• Never touch or try to stop a moving blade

with your hand.

16. When cutting dry - always unplug the water

pump first. Never run the pump dry.

• Do not use a wet cutting blade for dry

cutting. Select the proper dry cutting

blade for your application.

• Never make long continuous cuts with dry

cutting blades. To avoid heat build up,

allow the blade to cool, remove the tile

and allow the blade to run freely for a few

minutes.

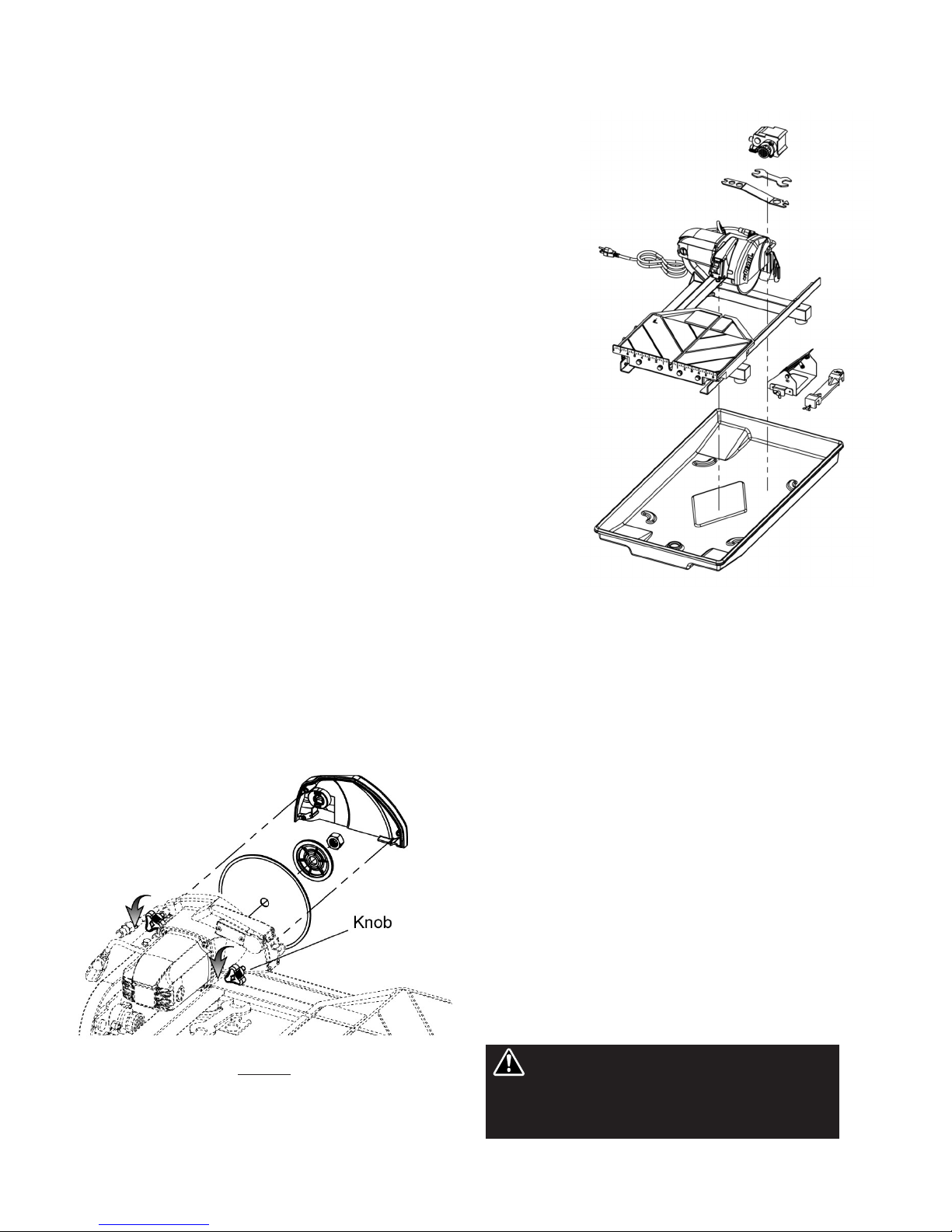

IMPORTANT - If there is any tendency for the

saw to tip or ove during certain operations,

such as when cutting large heavy tile; the saw

ust be securely fastened to a supporting

table.

17. Make certain all adjusting knobs or locks are

tight and engaged in their detents and that

movable parts not intended to move during

operation are securely locked before making a

cut. Be careful not to over tighten.

18. Before connecting the machine to a power

source check to see that the “On/Off” switch is

in the “off” position.

• Make sure the blade is not contacting

anything before connecting to a power

source and starting the motor.

• Know how to stop the machine quickly in

case of an emergency.

19. rounding Instructions

• In the event of a malfunction or

breakdown, grounding provides a path of

least resistance for electric current to

reduce the risk of electric shock. This tool

is equipped with an electric cord having

an equipment-grounding conductor and a

grounding plug. The plug must be

plugged into a matching outlet that is

properly installed and grounded in

accordance with all local codes and

ordinances.

• Do not modify the plug provided - if it will

not fit the outlet, have the proper outlet

installed by a qualified electrician.

• Improper connection of the equipment-

grounding conductor can result in a risk

of electric shock.

• Check with a qualified electrician or

service personnel if the grounding

instructions are not completely

understood, or if in doubt as to whether

the tool is properly grounded.

• Use only 3 wire extension cords that have

3 prong grounding plugs and 3 pole

receptacles that accept the tool’s plug.

Repair or replace damaged or worn cord immediately.

This tool is intended for use on a circuit that has an outlet

that looks like the one illustrated in Figure 6. The tool has

a grounding plug that looks like the plug illustrated in

Figure 6(A). A temporary adapter, which looks like the

adapter illustrated in Figure 6(B) and 6(C), may be used

to connect this plug to a 2 pole receptacle as shown in

Figure 6(B) if a properly grounded outlet is not available.

The temporary adapter should be used only until a

properly grounded outlet can be installed by a qualified

electrician. The green-colored rigid ear, lug, and the like,

extending from the adapter must be connected to a

permanent ground such as a properly grounded outlet

box.

Note: USE OF A TEMPORARY ADAPTER IS NOT

PERMITTED IN CANADA.

Additionally, water pump requires the use of a round

Fault Circuit Interrupter. Therefore, when using the water

pump receptacle, this tool must be plugged into a

properly installed round Fault Circuit Interrupter outlet.

See Figure 6(D). If a round Fault Circuit Interrupter

outlet is not available, Pearl Abrasive Co. has it available

as an accessory item. A plug-in round Fault Circuit

Interrupter may be plugged into a properly installed and

grounded 3-pole outlet. Refer to Figure 6(E).

20. Position of the Tile Saw

• To avoid the possibility of the appliance

plug or receptacle getting wet, position

tile saw to one side of a wall mounted

NOTE - Use of a Te porary Adapter is not per itted

in Canada.