– 8 –

nameplate. Do not operate any saw without

safety guards in place or with a blade diameter

larger than the maximum saw blade capacity.

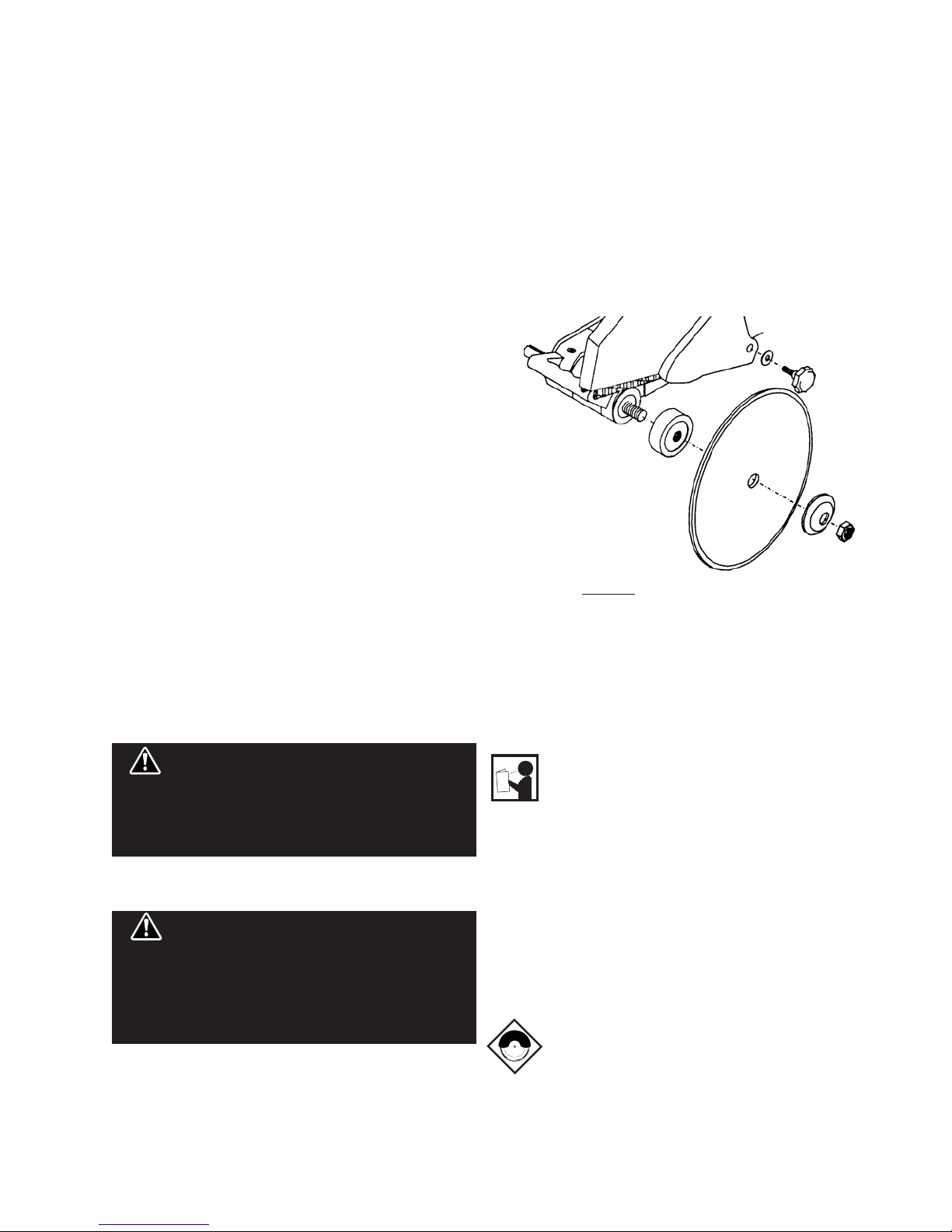

8. Before mounting a blade on the saw clean and

inspect the arbor shaft, blade flanges and the

diamond blade for uneven wear or damage. If

it appears to be damaged,

Do not operate the

tool.

Have it serviced by a qualified service

technician.

9. Before each use of the saw, inspect the

diamond blade for hairline fatigue cracks. If

such a crack or flaw is evident, discard the

blade.

Using a damaged blade may cause

injury to the operator or others.

10. Be sure that the blade arbor hole matches the

blade adapter flange supplied with the saw.

Use only blade adapter flanges that came on

your saw. Never use damaged or worn blade

adapter flanges.

11.

Installing the blade,

install the blade with the

arrow pointing the same direction as the

rotation of the arbor shaft or the arrow on the

blade guard. Be sure to tighten the blade shaft

arbor nut with the wrench provided.

Be careful not to over tighten.

12. Check that the blade tracks near the center of

the channel in the main table, and that the table

moves freely from front to back.

13. Sometimes the material being cut is not

abrasive enough to expose new diamonds on

the blade. If the blade is not sharpened, it will

rub against the surface resulting in heat build

up in the core. To prevent this, it is necessary

to dress the blade. To dress the blade simply

cut something that is very abrasive such as a

piece of cement block. Indications that the

blade needs dressing includes:

• The diamond in the matrix appear shiny

because they are worn flat.

• The blade stops cutting or noticeably

slows down.

Blade dressing stones are available from your local Pearl

Warehouse.

14. Before using the saw fill the water tub enough

to submerge the water pump with clean water

only. Replenish as necessary and clean the

water tub frequently. Do not operate a wet

cutting blade without adequate water flow to

both sides of the blade. Never run the pump

dry.

15. When cutting, always hold the material firmly

lying flat, supported by the main table with one

edge resting against the main table backstop.

• Do not attempt to cut pieces too small to

safely hold down on the main table.

• Never use the side of the blade to cut or

grind with, only cut in a straight line.

• Keep all parts of your body away from the

blade and all other moving parts.

• Never touch or try to stop a moving blade

with your hand.

16. When cutting dry - always unplug the water

pump first.

Never run the pump dry.

• Do not use a wet cutting blade for dry

cutting. Select the proper dry cutting

blade for your application.

• Never make long continuous cuts with dry

cutting blades. To avoid heat build up,

allow the blade to cool, remove the tile

and allow the blade to run freely for a few

minutes.

IMPORTANT - If there is any tendency for the

saw to tip or move during certain operations,

such as when cutting large heavy tile; the saw

must be securely fastened to a supporting

table.

17. Make certain all adjusting knobs or locks are

tight and engaged in their detents and that

movable parts not intended to move during

operation are securely locked before making a

cut.

Be careful not to over tighten.

18. Before connecting the machine to a power

source check to see that the “On/Off” switch is

in the “off” position.

Not dressing the blade

frequently or setting the blade too high will cause

it to grab the tile possibly causing injury to the

operator and the saw. Setting the blade depth too

low will cause it to cut into the main table that

may result in injury.

WARNING!