7 of 39 ISSUED: 06-05-06 SHEET #: 202-9141-5 12-05-06

IMPORTANT!Concretemustbe 2000 psi densityminimum.

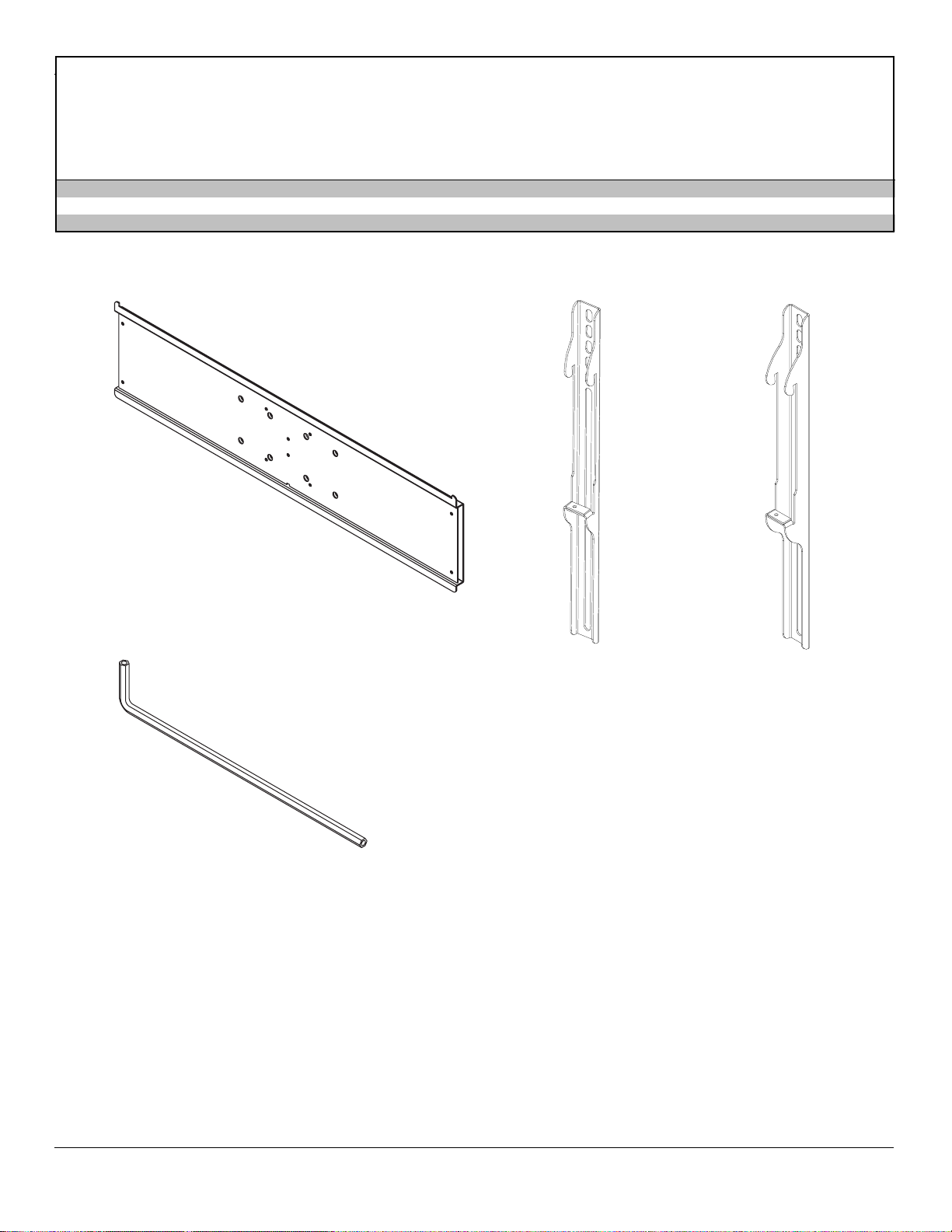

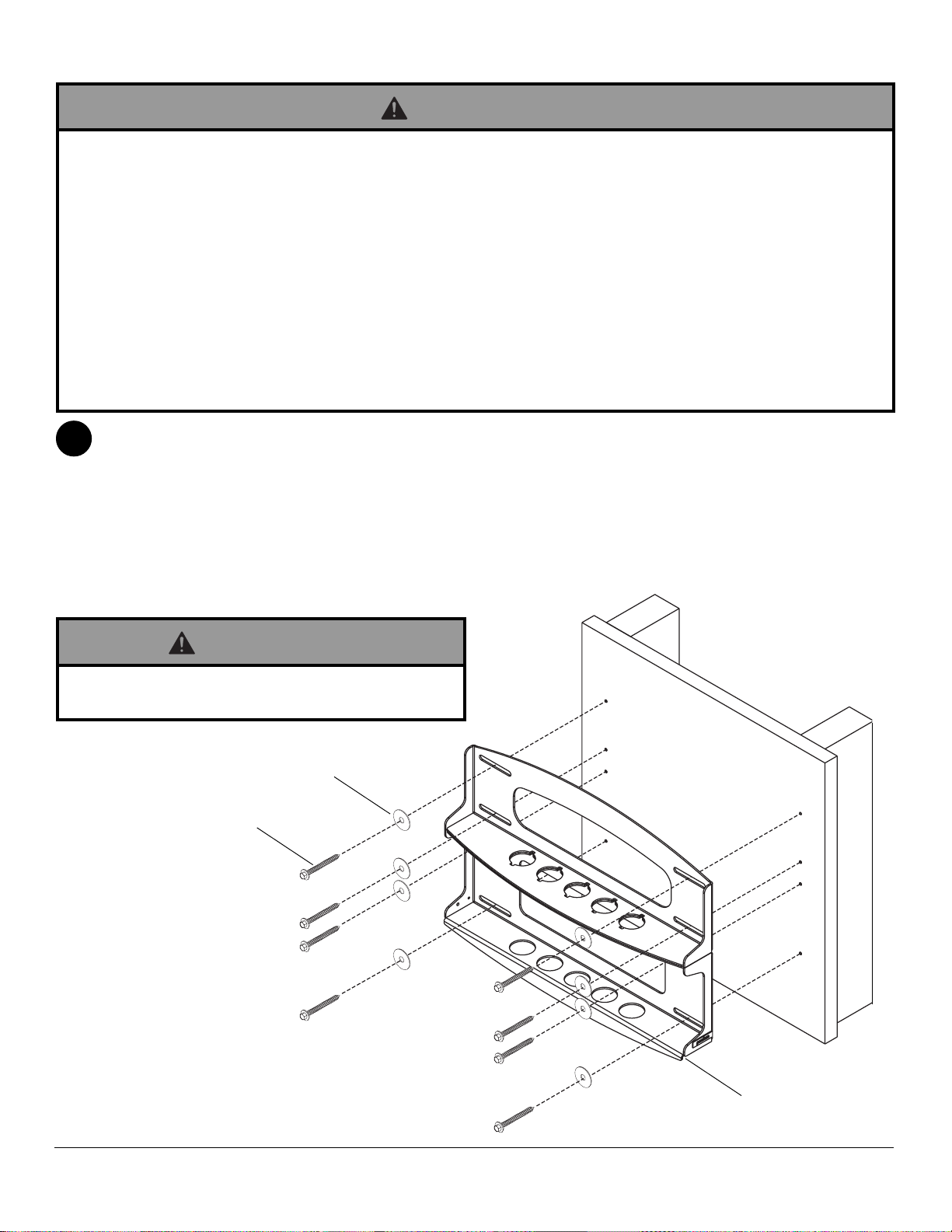

Use wall plate (A), making sure that it is level, as a

template to mark holes. The top mounting slots should

be located .36" above the desired screen center for PLA

60-UNL,PLA60-UNL-S,PLA60-UNLP,RTPLA60,PLA

60-UNLP-SandRTPLA60-Sand.43"belowthedesired

screencenter forPLAV60-UNL, PLAV 60-UNL-S,PLAV

60-UNLP,PLAV60-UNLP-S,RTPLAUN7,RTPLA

UN7S,D-FPA-320andD-FPA-320S.Usethemasonry

bit to drill 5/16" (8 mm) dia. holes to a minimum depth of

3" (76 mm). Insert anchors (W) in holes flush with wall as

shown(right).Placewallplate(A) overanchors(W)and

secure with 5/16 x 3" wood screws (O) and washers (P).

• Concrete must be 2000 psi density minimum. Lighter density concrete may not hold concrete anchor.

• Make sure that the supporting surface will safely support the combined load of the equipment and all attached

hardwareandcomponents.

• Neverexceed the Maximum UL Load Capacity of 175 lb (79 kg).

• Never mount this product to metal studs.

WARNING

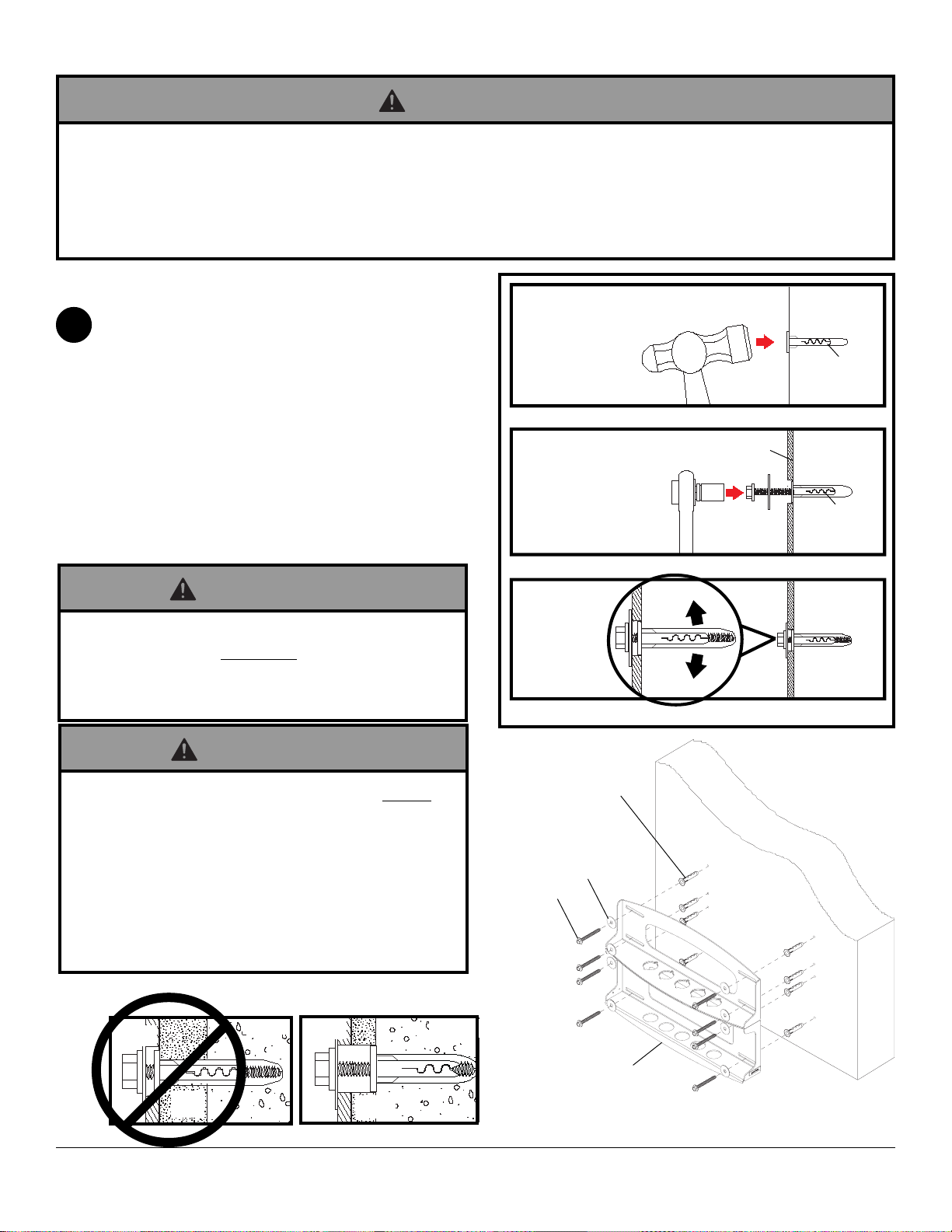

• Always attach concrete expansion anchors directly to

load-bearingconcrete.

• Neverattach concrete expansion anchors toconcrete

coveredwith plaster, drywall,or other finishing mate-

rial.If mounting to concrete surfaces covered witha

finishingsurface isunavoidable,the finishing surface

mustbe counterbored as shown below.If plaster/

drywall is thicker than 5/8", custom fasteners must be

suppliedby installer (Not evaluated byUL).

WARNING

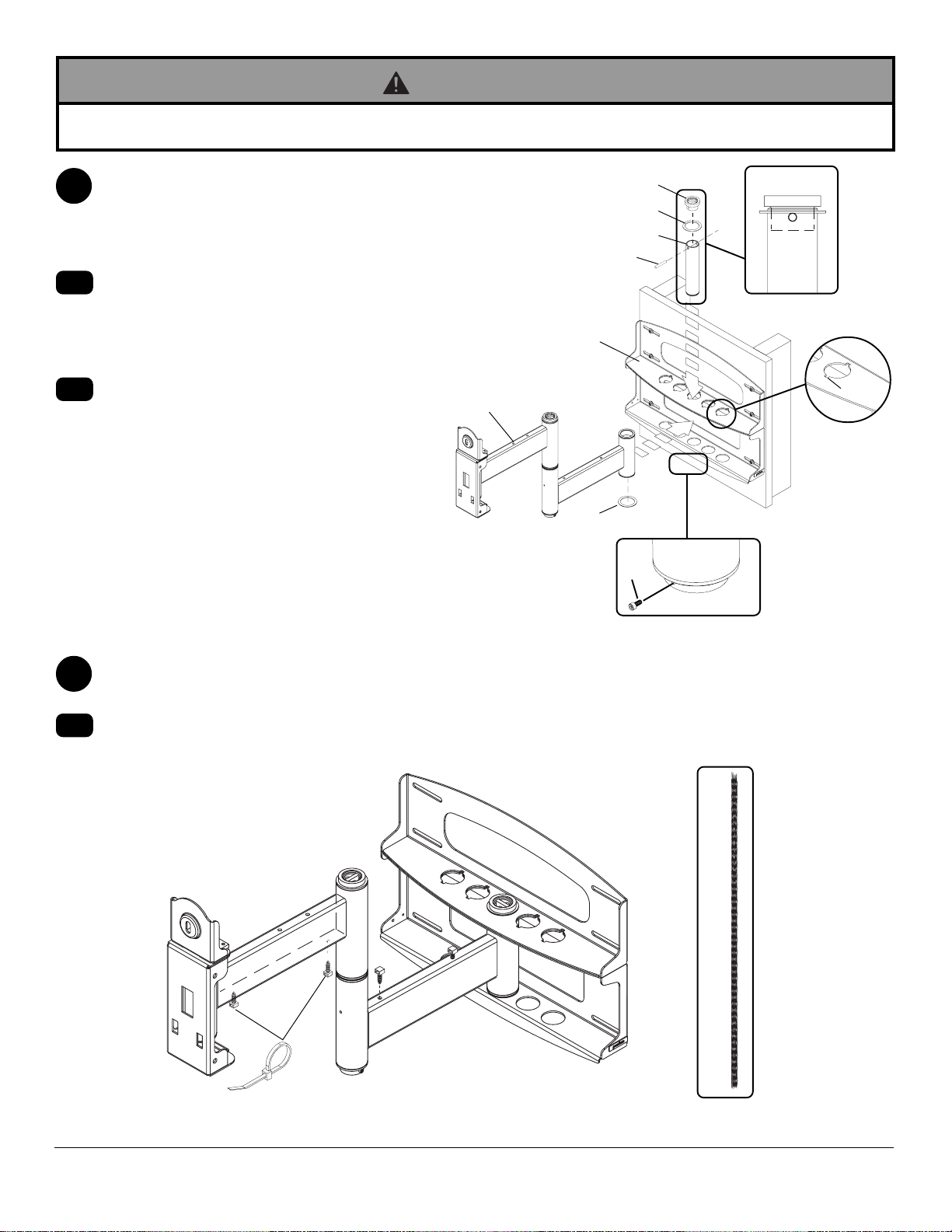

• Tighten wood screws so that wall plate is firmly

attached,but do notovertighten. Overtightening can

damagescrews, greatly reducingtheirholding power.

• Never tighten in excess of 80 in • lb (9 N.M.).

WARNING

1

Installation to Concrete Wall

INCORRECT CORRECT

A

OP

W

concrete

surface

1

3

2

Drill hole(s) and insert anchor(s) (W)

mounting

plate

Place plate over anchor(s) (W) and secure with screw(s)(O)

Tighten all fasteners

W

W

CUTAWAYVIEW

mounting

plate

plaster/

drywall

concrete mounting

plate concrete

plaster/

drywall