GENERAL INFORMATION

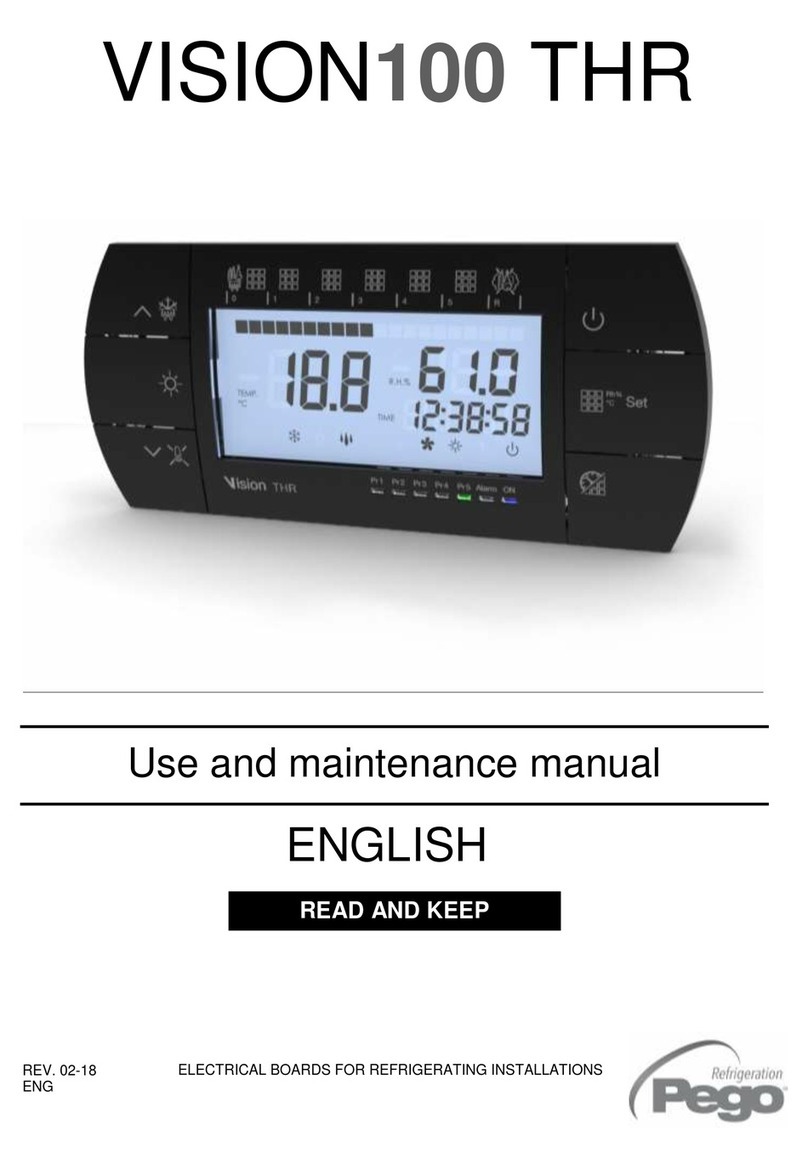

DESCRIPTION:

VISION TOUCH PAN enables advanced control of retarding cells, cabinets or counters

with temperature and humidity control.

The system consists of the 100N MASTER3 unit, on which all the electrical connections

are made, and the VISION TOUCH PAN control console, equipped with 7'' TFT display

with capacitive touch screen combined with a highly advanced software and a highly user

friendly interface that allows easy use.

APPLICATIONS:

-Retarding cabinets, counters and cells for industrial and in-store bakeries and

confectioneries.

-Replacing other retarding controls on existing systems.

TECHNICAL SPECIFICATIONS FOR RETARDING:

-Hot manual mode (leavening)

-Cold manual mode (accumulation)

-Manages automatic retarding programs that can be customised, consisting of a

maximum of 9 steps that can be set (2 accumulation phases, 3 preservation phases, 3

leavening phases and 1 resting phase); the following is possible for each phase:

Enable its operation (with the exception of Preservation phase 3 that is always present);

Set the functions enabled in the phase (Cold , Hot , Humidify and Dehumidify );

Phase duration, Temperature setpoint and Humidity setpoint;

Select the evaporator fan speed and continuous fan forcing;

Switch to enable temperature threshold management, below which humidity control is

inhibited;

Switch to enable defrosting for the accumulation and preservation phases. (At the

beginning of the leavening phase, a defrosting phase is launched, if enabled, and this is

then inhibited during the leavening and resting phases);

Switch to enable the gradual increase to reach the Temperature setpoint (only for the

leavening phases).

-Possibility of enabling a warning for the end of program and oven advance ignition

command.

-Store up to 12 programs in the internal memory with the option of exporting them to a

USB or microSD.

-Diagram of the program in execution with progress display (completed phases, phases

in progress and phases yet to be executed) and a representation of the set values and

of all the remaining times.

-Temperature adjustment range: -45°C/+99°C; humidity adjustment range: 0-100 R.H.%