V246 Series 2-Way Pressure-Actuated

Water-Regulating Valves for High-Pressure

Refrigerants Installation Guide

Applications

Important: The V246 Series 2-Way Pressure-

Actuated Water-Regulating Valves for High-Pressure

Refrigerants is intended to control coolant media

flow under normal operating conditions. Where

failure or malfunction of the V246 valve could

lead to personal injury or property damage to the

controlled equipment or other property, additional

precautions must be designed into the control

system. Incorporate and maintain other devices,

such as supervisory or alarm systems or safety or

limit controls, intended to warn of or protect against

failure or malfunction of the V246 valve.

Warning

Risk

This product is made of a copper alloy, which contains

lead. The product is therefore not to be used on drink-

ing water.

The V246 Series 2-Way Pressure-Actuated Water-

Regulating Valves for High-Pressure Refrigerants come

in two types of control action: direct acting and reverse

acting. V246 valves regulate water flow to control

refrigerant head pressure in systems with water-cooled

condensers.

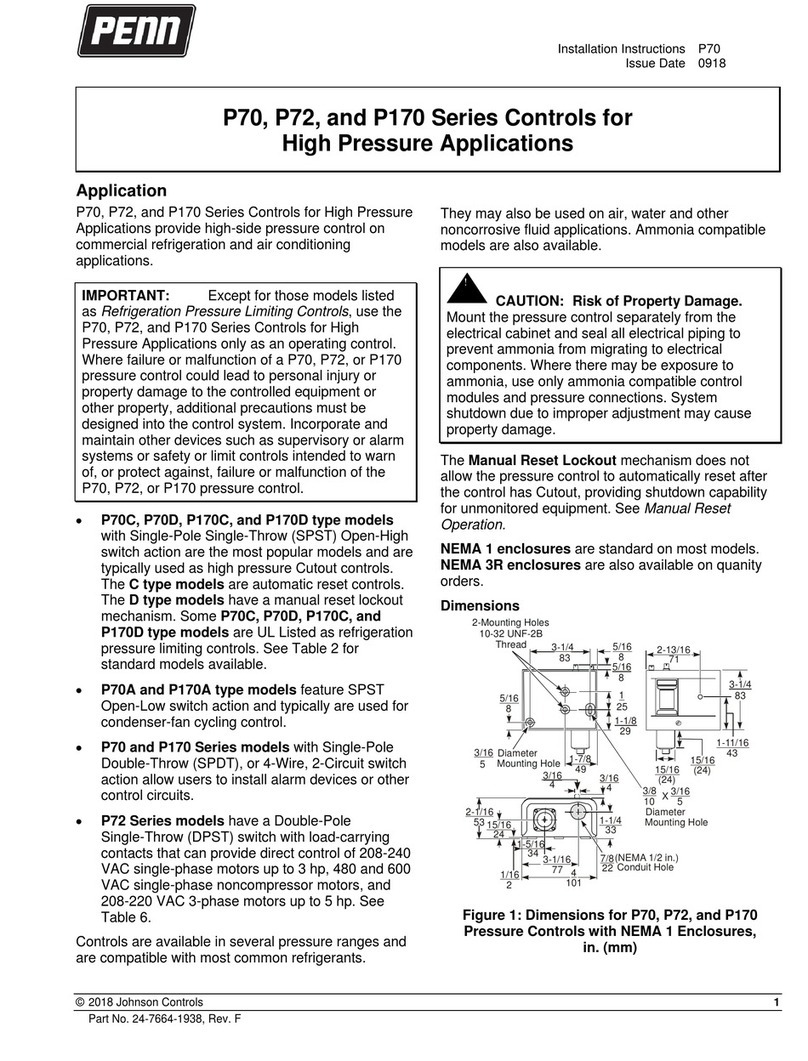

The V246 Series Valves are available in 3/8 in. through 2

in. sizes and have a maximum allowable water pressure

of 150 psi (10.3 bar). Direct acting V246 valves have an

adjustable opening point in a refrigerant pressure range

of 200 to 400 psi (13.8 to 27.6 bar), and reverse acting

valves have a range of 135 to 300 psi (9.3 to 20.7 bar).

V246 valves may be used with standard non-corrosive

refrigerants.

Maritime models, which have nickel copper (Monel®)

internal parts, are available for applications where the

coolant may be corrosive to the internal parts.

Installation

CAUTION

Risk of Environmental Damage

Provide proper containment for any potential release

of refrigerant, solvent, or oil. Such hazardous materials

can be harmful to the environment if they are released.

Important:

• If the V246 valve is installed on equipment that

contains hazardous or regulated materials

such as certain refrigerants or lubricants, you

must comply with all standards and regulations

governing the containment and handling of those

materials.

• After installing the V246 valve, evacuate pressure

connection lines to remove air, moisture, and

other contaminants in a manner consistent

with applicable environmental regulations and

standards.

• Take care to prevent foreign materials such as

weld slag, thread burrs, metal chips, and scale

from entering the piping system. This debris can

damage or severely impede the operation of the

valve by embedding itself in the seats, scoring the

valve, and ultimately resulting in seat leakage.

If the debris becomes embedded in the seats,

subsequent flushing and filtering of the piping

system with the valve installed does not remedy

the problem.

Install the valve vertically with the range adjustment

screw on the top, and the sensing element and pressure

connection line on the bottom, to allow oil and refrigerant

to drain away from the valve sensing element.

Mount the valve so that the valve sensing element is

above the refrigerant tap point, if possible. If it is not

possible to mount the bellows of the valve above the tap

point, loop the capillary above the tap point and below

the bellows and then connect to the valve. Tap off of the

topside of the high side line. This minimizes the effect of

refrigerant oil in the capillary on valve reaction time.

Do not mount the valve in any position other than vertical

unless specified by the manufacturer of the equipment

on which the valve is installed. Follow the manufacturer's

installation instructions.

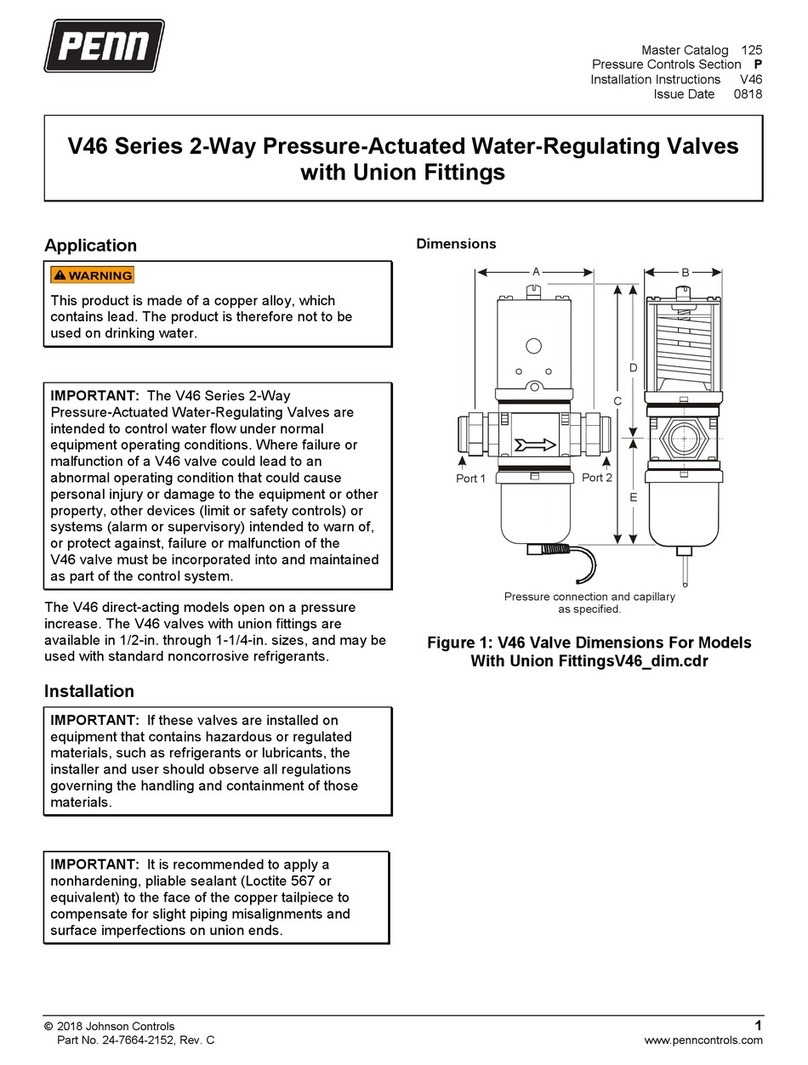

The direction of water flow is indicated by an arrow on the

valve body. See Figure 1.

Part No. 24-7664-2713 Rev. G

2019-06-20

V246