V43/V243 Series Pressure-Actuated Water-Regulating Valves Product/Technical Bulletin

3

When the head pressure rises, and the refrigerant

pressure overcomes the spring force (pilot valve), the

valve begins to open (the disk lifts off of the seat). This

point is called the opening point.

The opening point is adjusted by increasing or

decreasing the spring force by using the adjustment

stem. If the head pressure continues to rise, the

refrigerant pressure further opens the valve until the

valve is fully open. The range from the point where the

valve lifts off the seat (the opening point) to the point

where the valve is fully open is called the throttling

range.

The throttling range is fixed and cannot be adjusted.

The throttling range is approximately 40 psig for the

low-pressure V43 Series Valves, approximately 50 psi

for the medium-pressure V43 Series Valves, and

approximately 60 psi for the high pressure V243 Series

Valves.

Head Pressure Rise Above the Opening Point

When the head pressure rises, the force of the

refrigerant head pressure overcomes the spring force

(plus any hysteresis) and pushes the disc off the seat,

allowing water to start flowing through the valve.

Anything above that point is head pressure rise above

the opening point. Typically, the opening point is

approximately 7 psi above the closing point.

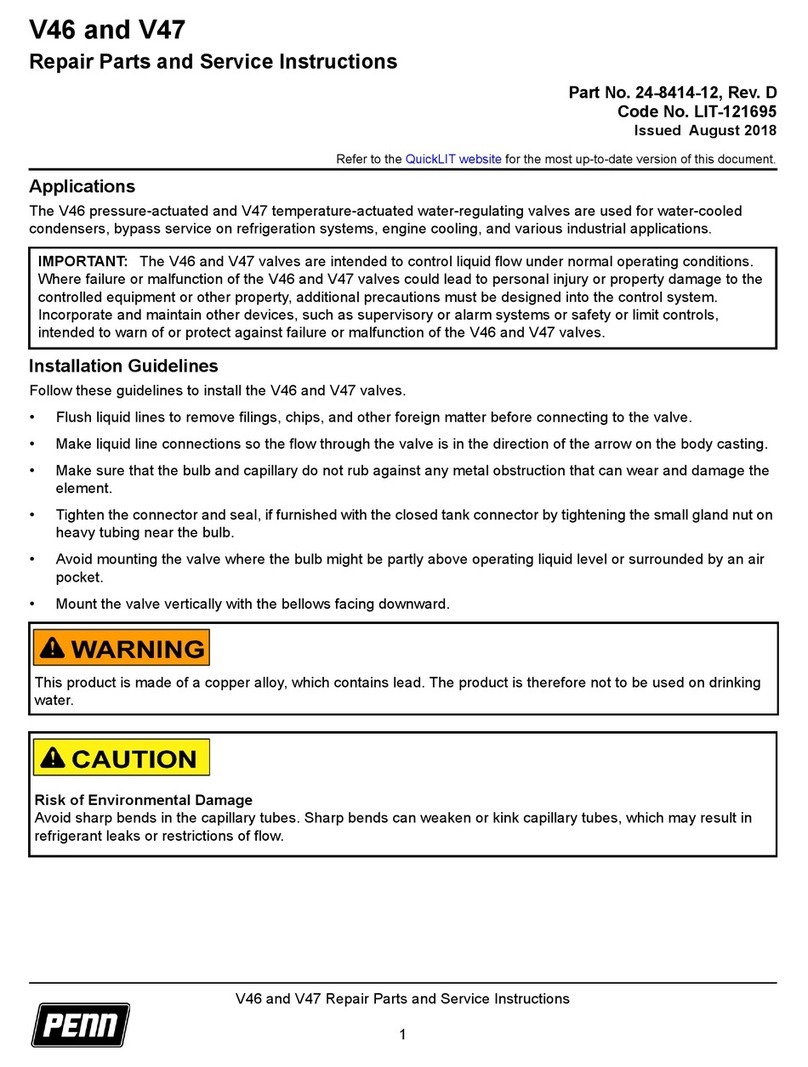

Proper Valve Size

A properly sized valve meets the requirements of the

maximum water flow required yet functions at an

acceptable level when minimum flow is required (does

not water hammer, cut, or wire draw the seats and

seating discs). See Figure 3 and Figure 4 to select the

correct valve size for your application.

Use the following steps to help determine the

appropriate valve size for your application:

1. Locate the point where the valve is fully open on

the Refrigerant Head Pressure Rise Above Valve

Opening Point (y-axis).

2. Draw a horizontal line from this point to where the

line intersects with the Water Pressure Available

WPA curve. This is Point A.

3. Draw a vertical line from point A to where it

intersects with Maximum Water Flow Available line

(x-axis). This is Point B.

Point B is the maximum amount of water that the

valve can flow, when fully open, under the stated

conditions. See Figure 3.

4. Locate the Maximum Water Flow Required for your

application (x-axis). This is Point C.

5. Draw a vertical line from Point C to where the line

intersects with the WPA curve. This Point D.

6. Draw a horizontal line from Point D to the left

where it intersects with the Refrigerant Head

Pressure Rise Above Opening Point.

This is where the selected value meets the

maximum flow requirement of the application.

Use the flow charts to select the valve that is most

appropriate for your application.

Example

In this example, the required flow for an R-404A

system is 300 GPM. The cooling tower pump discharge

pressure is 30 psig, and the condenser manufacturer's

table gives a pressure drop through the condenser at

8 psid. The pressure drop through the installed piping,

fittings, and valves is approximately 12 psi.

Maximum Water Flow Required = 300 GPM

Water Pressure Available= 30 - (12 + 8)

Water Pressure Available= 10 psid

You need to select the proper valve size. The proper

size valve is indicated by the flow chart that slightly

exceeds the maximum required flow when the valve is

wide open.

Refrigerant

Head

Pressure

Rise Above

Opening

Point

Refrigerant Head

Pressure at

Opening Point

=

Refrigerant

Head Pressure greater

than Opening Point

-

Water Pressure Available Across Valve (psid)

Maximum Water Flow Required

Value Determined in Step 1

Difference ensures

that the valve

meets the maximum

flow rate required.

CAPACITY CHART REPRESENTING

THE PROPER VALVE SIZE

Refrigerant Head Pressure Rise Above

Valve Opening Point (psig)

Point B

WPA Curve

Point C

Point A

FIG:capacity chart

Point D