Installation Instructions P70

Issue Date 0918

© 2018 Johnson Controls 1

Part No. 24-7664-1938, Rev. F

P70, P72, and P170 Series Controls for

High Pressure Applications

Application

P70, P72, and P170 Series Controls for High Pressure

Applications provide high-side pressure control on

commercial refrigeration and air conditioning

applications.

IMPORTANT: Except for those models listed

as Refrigeration Pressure Limiting Controls, use the

P70, P72, and P170 Series Controls for High

Pressure Applications only as an operating control.

Where failure or malfunction of a P70, P72, or P170

pressure control could lead to personal injury or

property damage to the controlled equipment or

other property, additional precautions must be

designed into the control system. Incorporate and

maintain other devices such as supervisory or alarm

systems or safety or limit controls intended to warn

of, or protect against, failure or malfunction of the

P70, P72, or P170 pressure control.

P70C, P70D, P170C, and P170D type models

with Single-Pole Single-Throw (SPST) Open-High

switch action are the most popular models and are

typically used as high pressure Cutout controls.

The C type models are automatic reset controls.

The D type models have a manual reset lockout

mechanism. Some P70C, P70D, P170C, and

P170D type models are UL Listed as refrigeration

pressure limiting controls. See Table 2 for

standard models available.

P70A and P170A type models feature SPST

Open-Low switch action and typically are used for

condenser-fan cycling control.

P70 and P170 Series models with Single-Pole

Double-Throw (SPDT), or 4-Wire, 2-Circuit switch

action allow users to install alarm devices or other

control circuits.

P72 Series models have a Double-Pole

Single-Throw (DPST) switch with load-carrying

contacts that can provide direct control of 208-240

VAC single-phase motors up to 3 hp, 480 and 600

VAC single-phase noncompressor motors, and

208-220 VAC 3-phase motors up to 5 hp. See

Table 6.

Controls are available in several pressure ranges and

are compatible with most common refrigerants.

They may also be used on air, water and other

noncorrosive fluid applications. Ammonia compatible

models are also available.

CAUTION: Risk of Property Damage.

Mount the pressure control separately from the

electrical cabinet and seal all electrical piping to

prevent ammonia from migrating to electrical

components. Where there may be exposure to

ammonia, use only ammonia compatible control

modules and pressure connections. System

shutdown due to improper adjustment may cause

property damage.

The Manual Reset Lockout mechanism does not

allow the pressure control to automatically reset after

the control has Cutout, providing shutdown capability

for unmonitored equipment. See Manual Reset

Operation.

NEMA 1 enclosures are standard on most models.

NEMA 3R enclosures are also available on quanity

orders.

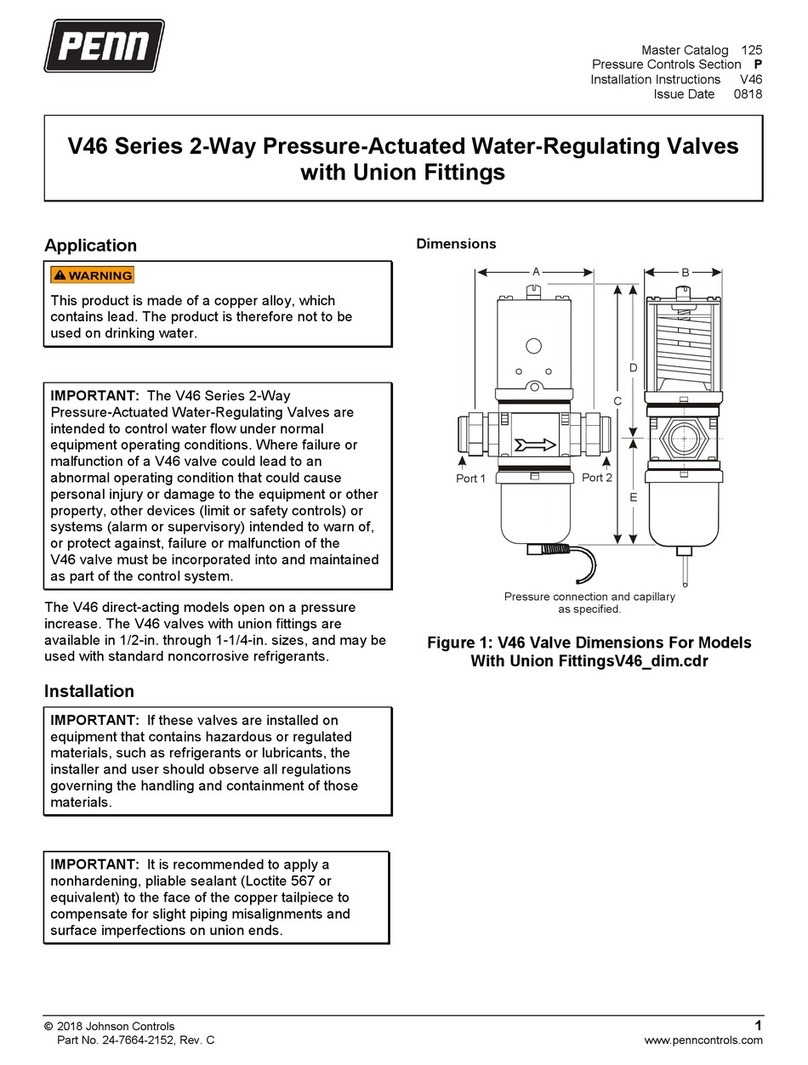

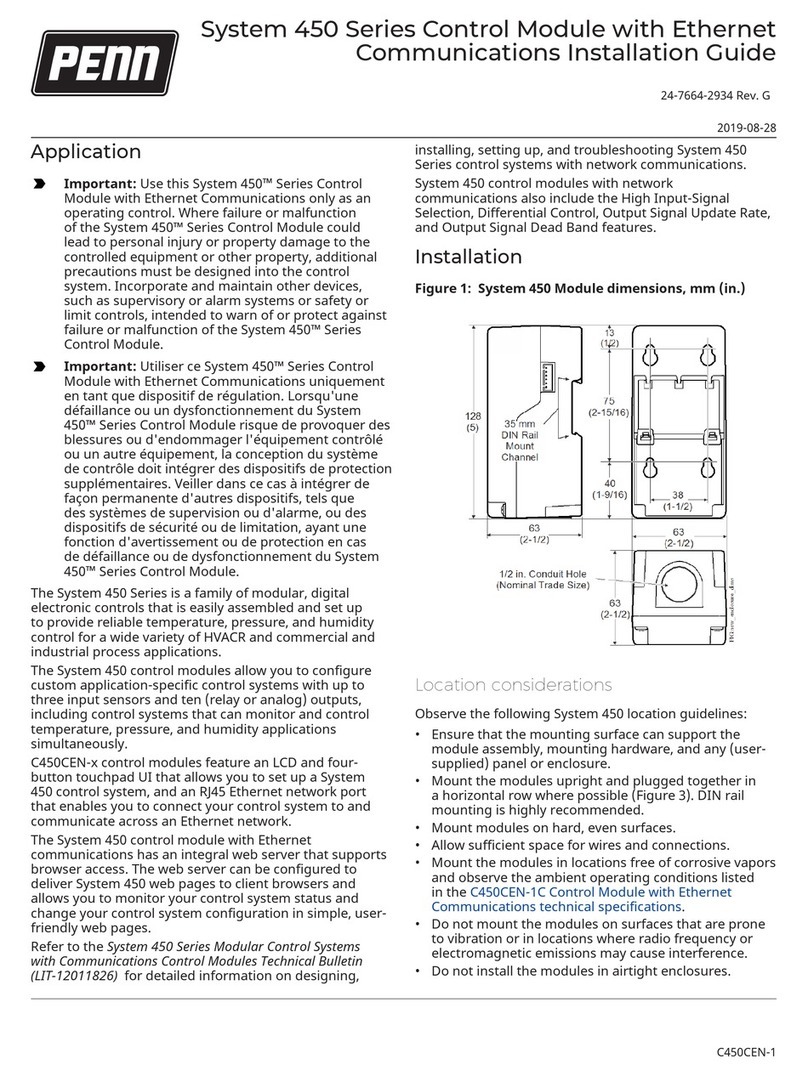

Dimensions

Mounting Hole

3/16

5Diameter

2-Mounting Holes

10-32 UNF-2B

Thread

4

101

3-1/16

77

1-5/16

34

1/16

2

15/16

24

2-1/16

53 1-1/4

33

3/16

4

3/16

4

7/8

22 Conduit Hole

5/16

8

3-1/4

83 5/16

8

1

25

1-1/8

29

1-7/8

49

5/16

8

3/8

10 X3/16

5

Diameter

Mounting Hole

(NEMA 1/2 in.)

3-1/4

83

2-13/16

71

1-11/16

43

15/16

(24)

15/16

(24)

Figure 1: Dimensions for P70, P72, and P170

Pressure Controls with NEMA 1 Enclosures,

in. (mm)