Deinstallation

DANGER

DANGER: contaminated parts

Contaminated parts can be detrimental to health

and environment.

Before beginning to work, find out whether any

parts are contaminated. Adhere to the relevant

regulations and take the necessary precautions

when handling contaminated parts.

Caution

Caution: vacuum component

Dirt and damages impair the function of the

vacuum component.

When handling vacuum components, take

appropriate measures to ensure cleanliness and

prevent damages.

Vent the vacuum system and wait until the valve has

cooled down to <50 °C.

Detach the flanges and put the protective lids in place.

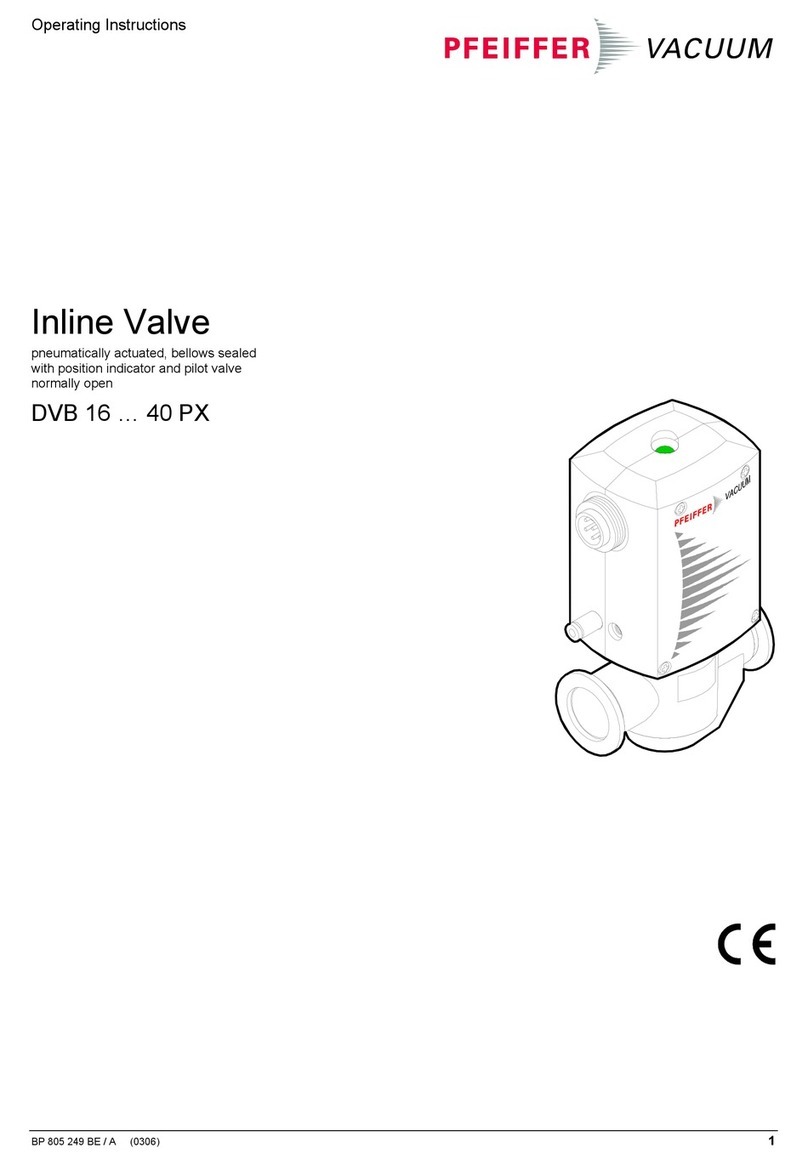

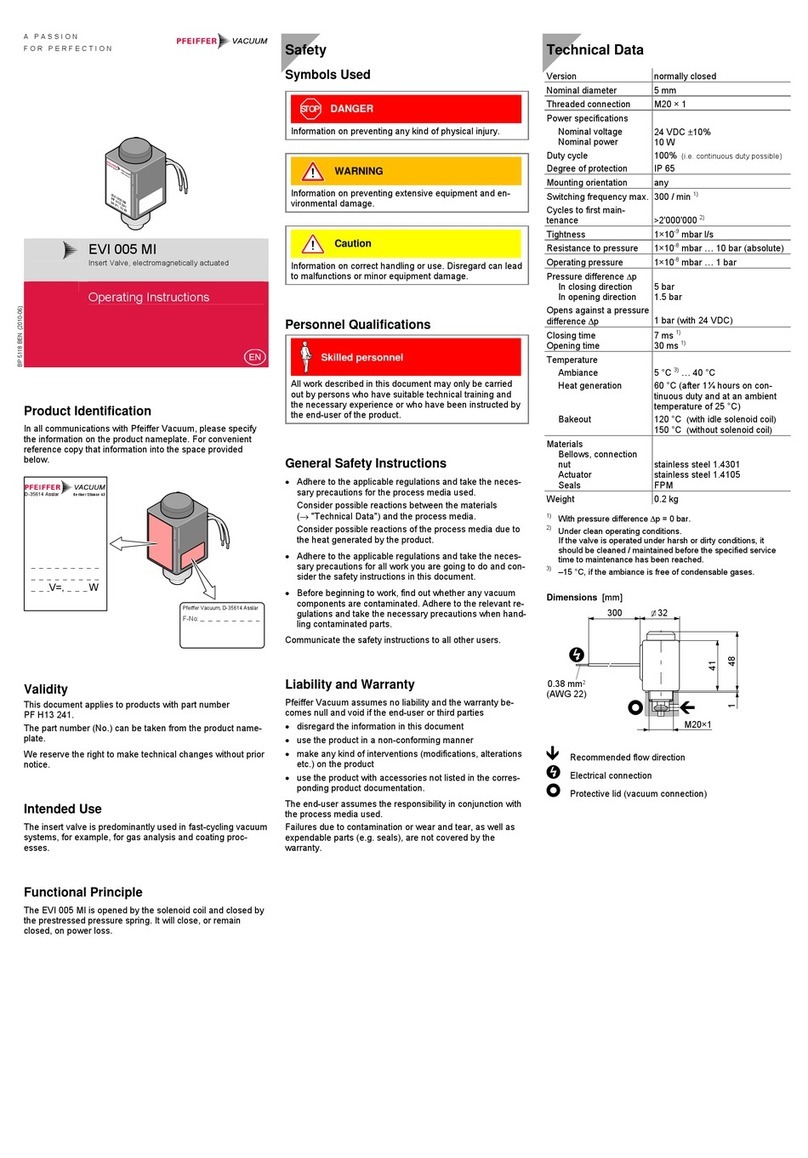

CF flange

Hex nut

Hex head screw

Washer

Protective lid

Seal

When the valve is reinstalled, replacing the seals is

recommended (→"Installation").

Maintenance/Repair

→[1]

Storage

Caution

Caution: vacuum component

Inappropriate storage leads to an increase of the

desorption rate and/or may result in mechanical

damage of the product.

•Cover the vacuum ports of the product with

protective lids or grease free aluminum foil.

•Close the valve up to the stop position (which

ensures optimum storage).

•Do not exceed the admissible storage

temperature range (→Technical Data).

Returning the Product

WARNING

WARNING: forwarding contaminated products

Contaminated products (e.g. radioactive, toxic,

caustic or biological hazard) can be detrimental

to health and environment.

Products returned to Pfeiffer Vacuum should

preferably be free of harmful substances. Ad-

here to the forwarding regulations of all involved

countries and forwarding companies and en-

close a duly completed declaration of contami-

nation *).

*) Form under www.pfeiffer-vacuum.net

Products that are not clearly declared as "free of harmful

substances" are decontaminated at the expense of the

customer.

Products not accompanied by a duly completed declaration

of contamination are returned to the sender at his own

expense.

Disposal

DANGER

DANGER: contaminated parts

Contaminated parts can be detrimental to health

and environment.

Before beginning to work, find out whether any

parts are contaminated. Adhere to the relevant

regulations and take the necessary precautions

when handling contaminated parts.

N

WARNING

WARNING: substances detrimental to the

environment

Products or parts thereof (mechanical and

electric components, operating fluids etc.) can

be detrimental to the environment.

Dispose of such substances in accordance with

the relevant local regulations.

Separating the components

After disassembling the product, separate its components

according to the following criteria:

•Contaminated components

Contaminated components (radioactive, toxic, caustic, or

biological hazard etc.) must be decontaminated in accor-

dance with the relevant national regulations, separated

according to their materials, and disposed of.

•Other components

Such components must be separated according to their

materials and recycled.

Literature

[1] www.pfeiffer-vacuum.net

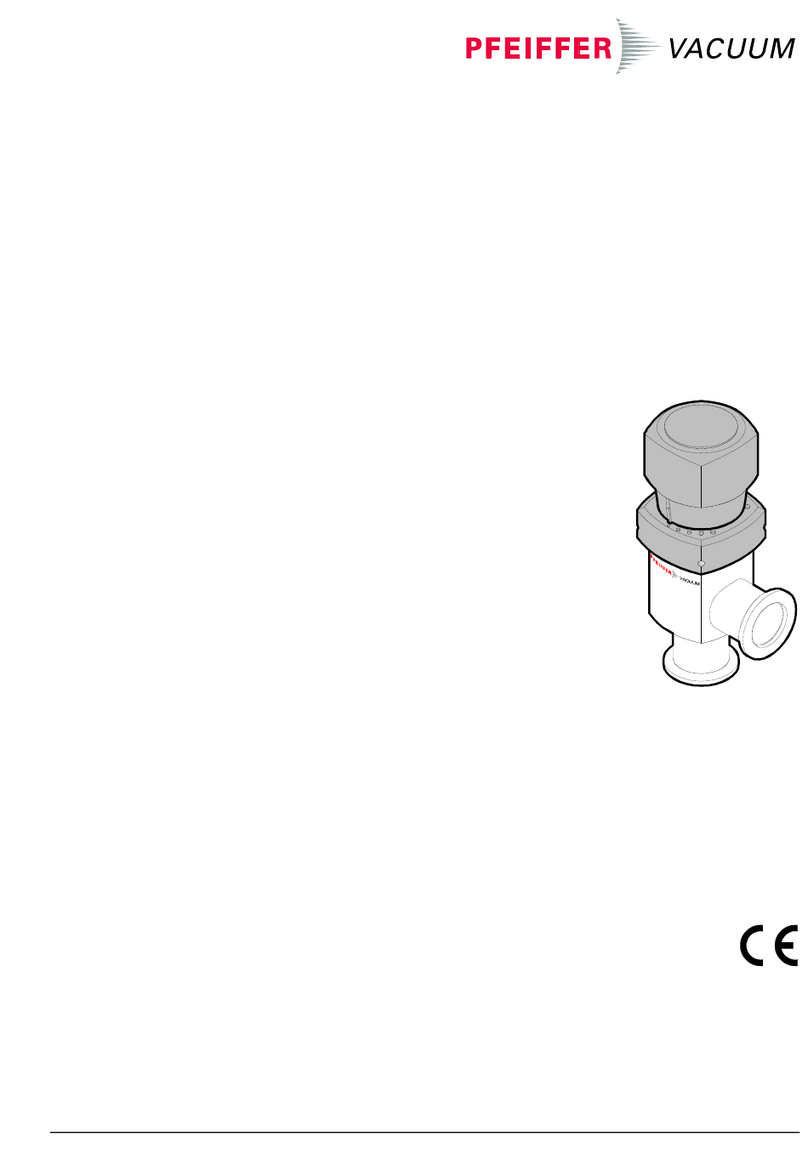

Operating Instructions

Angle Valve UVH 016 … 063 VI

BP 5277 BDE (German)

BP 5277 BEN (English)

Pfeiffer Vacuum GmbH, D–35614 Asslar,

Deutschland

Berliner Straße 43

D–35614 Asslar

Deutschland

Tel +49 (0) 6441 802-0

Fax +49 (0) 6441 802-202

www.pfeiffer-vacuum.net