System 450™ Series Expansion Modules with Relay Outputs Installation Instructions

5

Technical Specifications

C450Sxx-3 Series Expansion Modules with Relay Outputs

Product C450SBN-3: System 450 Expansion Module with one SPDT output relay

C450SCN-3: System 450 Expansion Module with two SPDT output relays

C450SBG-3: System 450 Expansion Module with one SPDT low current/voltage output relay

C450SCG-3: System 450 Expansion module with two SPDT low current/voltage output relays

Supply Power C450YNN-1 Power Supply Module

-or-

Separately supplied: 24 (20-30) VAC, 50/60 Hz, 10 VA minimum Class 2 (North America),

Safety Extra-Low Voltage (SELV) (Europe)

Ambient Operating

Conditions

Temperature: -40 to 66C (-40 to 150F)

Humidity: Up to 95% RH non-condensing; maximum dew point 29C (85F)

Ambient Shipping and

Storage Conditions

Temperature: -40 to 80C (-40 to 176F)

Humidity: Up to 95% RH non-condensing; maximum dew point 29C (85F)

Output Relay Contacts C450SxN-3

General: 1/2 HP at 120/240 VAC, SPDT

Specific: AC Motor Ratings 120 VAC 208/240 VAC

AC Full-load amperes: 9.8 A 4.9 A

AC Locked-rotor amperes: 58.8 A 29.4 A

_____________________________________

10 amperes AC non-inductive at 24/240 VAC

Pilot Duty: 125 VA at 24/240 VAC

C450SxG-3

General: 2 amperes resistive at 48 VDC

Pilot Duty: 360 VA at 120 VAC

Maximum Dry Circuit Rating: Resistive only, 400 mW at 28 VAC/VDC

Note: Once a relay has been used at the General Rating level, the Dry Circuit Rating is no

longer valid.

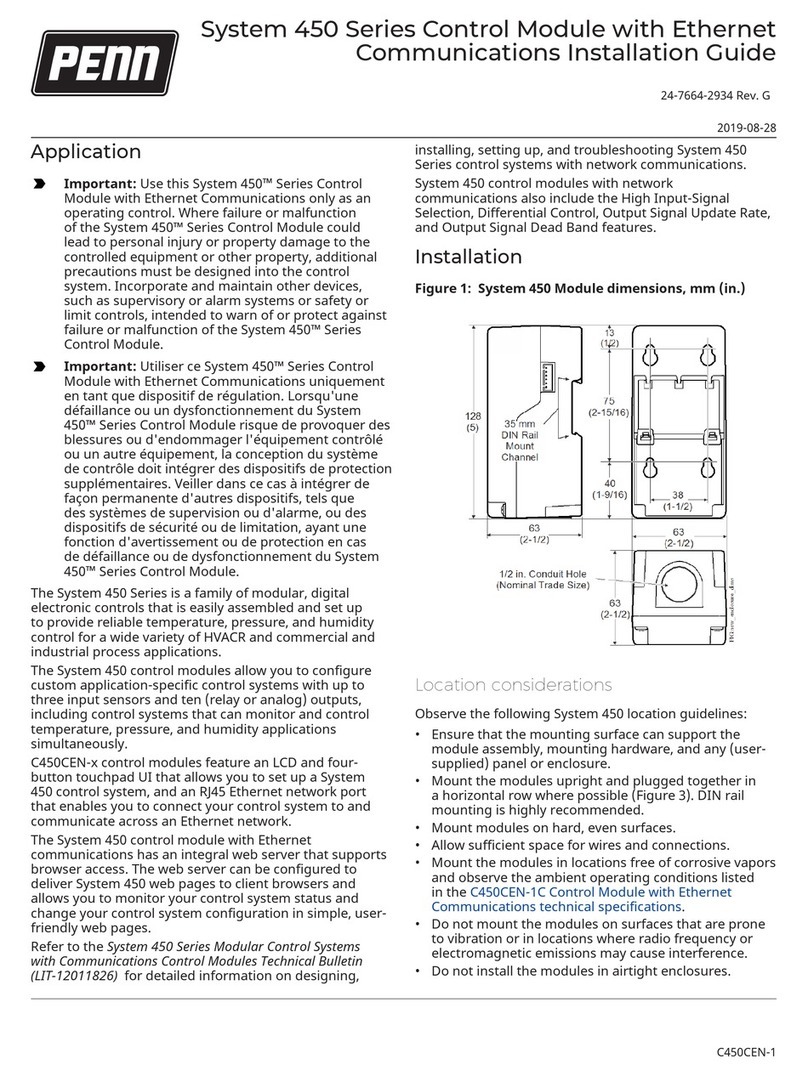

Control Construction Independently mounted control, surface mounted with Lexan® 950 enclosure suitable for DIN

rail mounting or direct mounting to a hard, even surface.

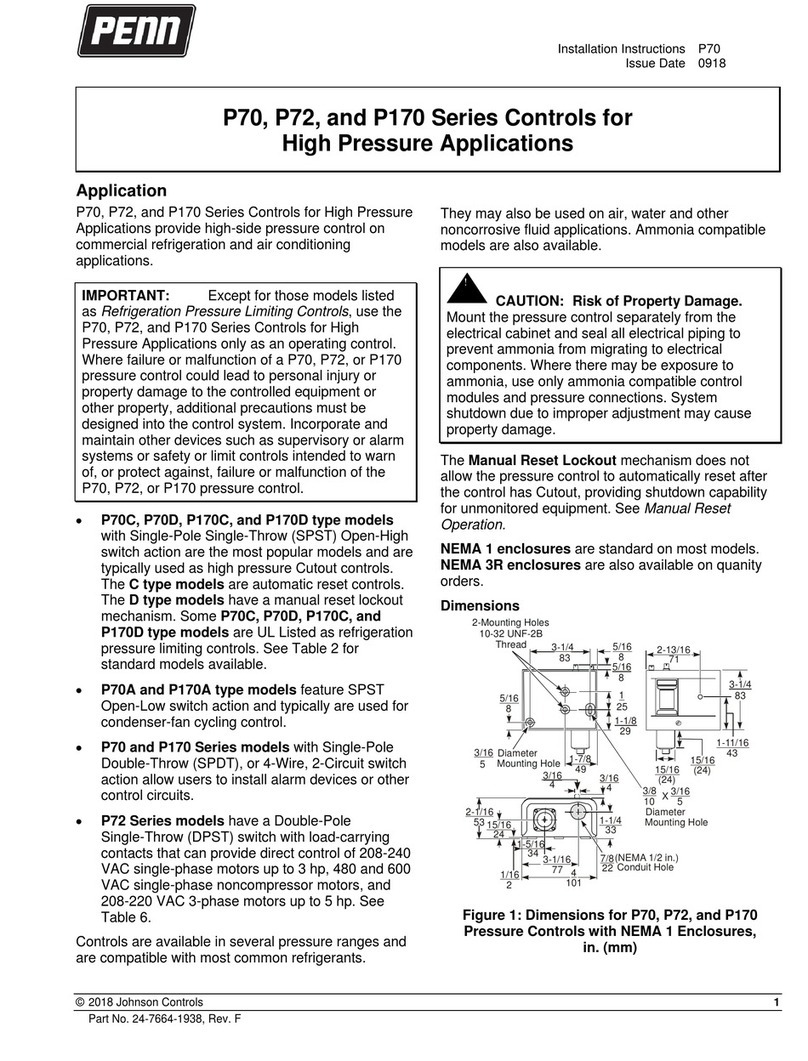

Dimensions (H x W x D) 127 x 61 x 61 mm (5 x 2-3/8 x 2-3/8 in.)

Weight C450SBx-3: 172 g (0.38 lb)

C450SCx-3: 186 g (0.41 lb)

Compliance United States: cULus Listed; UL 60730-1, File E27734; FCC Compliant to CFR47, Part 15,

Subpart B, Class B

Canada: cULus Listed; CAN/CSA-E60730-1, File E27734; Industry Canada (IC) Compliant to

Canadian ICES-003, Class B limits

Europe: CE Mark – Johnson Controls declares that this product is in compliance with the

essential requirements and other relevant provisions of the EMC Directive.

Australia and New Zealand: RCM Mark, Australia/NZ Emissions Compliant

The performance specifications are nominal and conform to acceptable industry standards. For application at conditions beyond these

specifications, consult Johnson Controls Application Engineering at (414) 524-5535. Johnson Controls shall not be liable for damages

resulting from misapplication or misuse of its products.