8

ENGLISH

ALARM AND ERROR SIGNALS

If alarms (conditions not prejudicing gate operation) or errors

(conditions preventing the gate from operating), the display

shows the number referring to the condition.

AS

ASSISTANCE REQUEST – CYCLES COUNTER (coupled to the next

two functions):

Y = When the number of cycles settable with the following nc

and nd functions is reached, this facility pre-flashes for 8

sec. (in addition to the pre-flashing already set with the PF

function) before every movement.

no = the following functions

nc and nd

indicate how many cycles

the system effected up to a maximum displayable amount

of 99.990.

no no no no

nc

CYCLE PROGRAMMING (THOUSANDS):

If AS = Y, the display indicates the number of the thousands of

cycles after which assistance is requested (settable from 0

to 99).

If AS = no, the display indicates the number of the thousands of

effected cycles. The displayed value updates itself as the

cycles follow, interacting with the nd values.

00 00 00 00

nd

CYCLE PROGRAMMING (TENS):

If AS = Y, the display indicates the number of tens of cycles after

which assistance is requested (settable from 0to 99).

If AS = no, the display indicates the number of the tens of

effected cycles. The displayed value updates itself as the

cycles follow, interacting with the nc values.

00 00 00 00

Display Function Default

0

Default

1

Default

2

Default

3

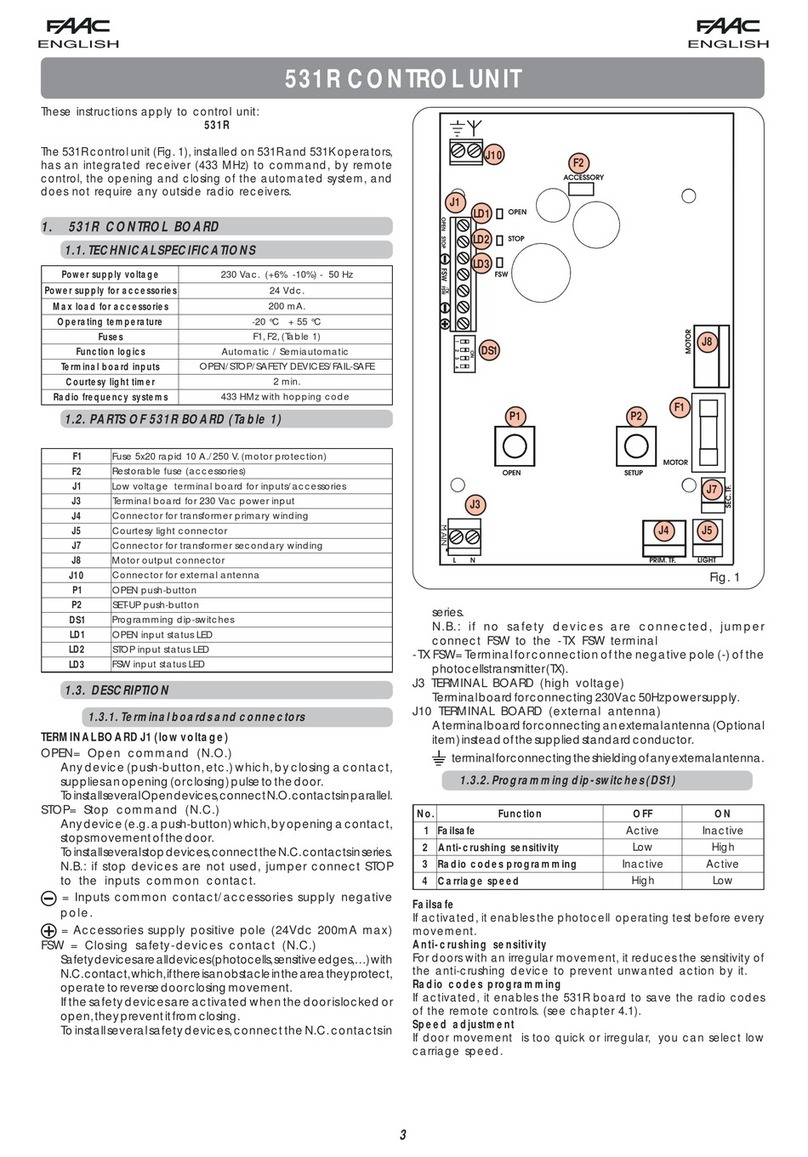

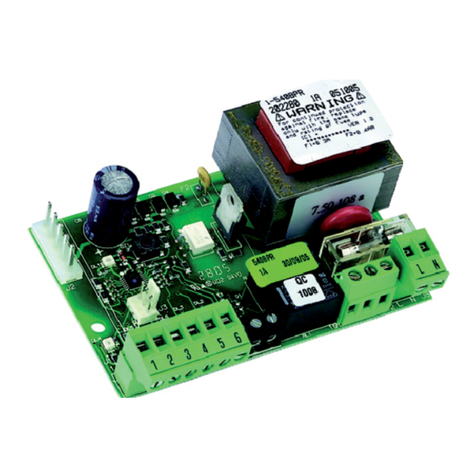

START-UP

TIME LEARNING - SETUP

By powering up the board if a SETUP was never

executed, or if the board requests it, the letters

S0 together with the SETUP (DL18) LED flash on

the display, to indicate that the SETUP must be

executed. Take the leaves to halfway their

travel (very important for a successful SETUP).

Hold down the SETUP (SW3) push-button, until the SETUP

(DL18) LED goes OFF and leaf 2 (if present) begins the

slowed down closing movement, stopping when it reaches

the mechanical stop point. At this stage, S1 flashes on the

display (setup: FIRST CLOSURE LEAF 2)

Leaf 1 starts the slowed down closing movement, stopping

when it reaches the closing mechanical stop. At this stage,

S2 flashes on the display (setup: FIRST CLOSURE LEAF 1)

Leaf 1 begins the slowed down opening movement,

followed by leaf 2 (if present) also slowed down. At this

stage, S4 flashes on the display (setup: OPEN)

When the opening mechanical stop point is reached, both

leaves stop and leaf 2 (if present) automatically restarts

to close at full speed, followed by leaf 1. At this stage, S5

flashes on the display (setup: FAST CLOSE).

When the closing mechanical stop point is reached, both

leaves stop and leaf 1 restarts to open automatically at

full speed followed by leaf 2 (if present). At this stage, S6

flashes on the display (setup: FAST OPEN).

If an automatic logic was selected, the board counts the

set pause and automatically closes the gate. Otherwise,

give an OPEN pulse to close the gate.

1.

2.

3.

4.

5.

6.

2 2 Limited current MOT1

2 3 Limited current MOT2

2 4 LAMP output short circuited

2 5 LOCK output short circuited

3 0 XF-module radio codes memory full

3 5 Timer function active

4 0 Cycles programmed at second programming level

(n C ) exhausted.

4 5 Battery operation

0 1 Board failure

0 2 Thermal protection active

0 3 Motor 1 faliure

0 4 Motor 2 faliure

0 5 Last movement performed

1 0 Both motor 1 travel limit devices engaged

1 1 Both motor 2 travel limit devices engaged

1 5 Time-out elapsed

1 7 Motor 1 encoder failure

1 8 Motor 2 encoder failure

These signals will disappear during the following

cycle only if the cause is removed.When an ALARM occurs,

LED DL20 starts to flash. When an ERROR occurs, LED DL20

goes ON at steady beam. If you simultaneously press keys

+ and – the display will show the number of the fault in

progress, as shown in the following table.