The A421 with Defrost Control is typically used to provide temperature control and adjustable,

timed, passive defrost cycles on medium temperature cooling applications such as reach-in boxes,

display cases, and walk-in coolers.

Parts included

Each A421 Control includes a Johnson Controls® or PENN® A99 Series temperature sensor. See A99

Series Temperature Sensors, Wiring, and Technical specifications for more information about A99

sensors.

A99 Series Temperature Sensors

The A421 Controls require an A99 sensor, and each A421 Control includes an A99 sensor. Any A99

Series sensor works with the A421 Series Controls. Do not replace an A99 Series sensor with any

other brand, series, or type of temperature sensor. See Ordering information for available A99

Series sensor models.

You can extend the sensor leads in the field. See Table 1 for wire sizes and lengths. On long sensor

cable runs, use shielded cable to reduce electromagnetic interference (EMI). Observe EMI best

practices when you route sensor leads.

Do not immerse the A99 Series sensors in water or any other liquid. The A99 sensors are moisture

tolerant and splash resistant but if you immerse the sensor, liquid can enter the sensor probe

where the steel tube meets the wire cable and result in sensor failure, which voids any warranty.

In applications where the sensor may be exposed to a lot of moisture, splashing, or rain, it is best

practice to mount the sensor in a vertical position with the cable at the bottom routed downward

so that moisture can drain away from the steel probe. Use a suitable bulb well for complete fluid

immersion applications. See Ordering information for information about bulb wells.

The A99 Series sensors are positive temperature coefficient (PTC) sensors. To test an A99 sensor,

disconnect the sensor from the control and measure the resistance between the sensor leads in the

following situations:

• When the temperature at the sensor is 77°F (25°C), the resistance should be 1,035 ohms.

• When the temperature at the sensor is 32°F (0°C), the resistance should be 855 ohms.

See Troubleshooting for more information.

When you connect an A99 sensor to a standard A421 Control, the control restricts the range of

usable values from -40°F to 212°F (-40°C to 100°C).

See Wiring, Technical specifications, and refer to the A99B Series Temperature Sensors Product/

Technical Bulletin (LIT-125186) for more information about A99 Series sensors.

Mounting

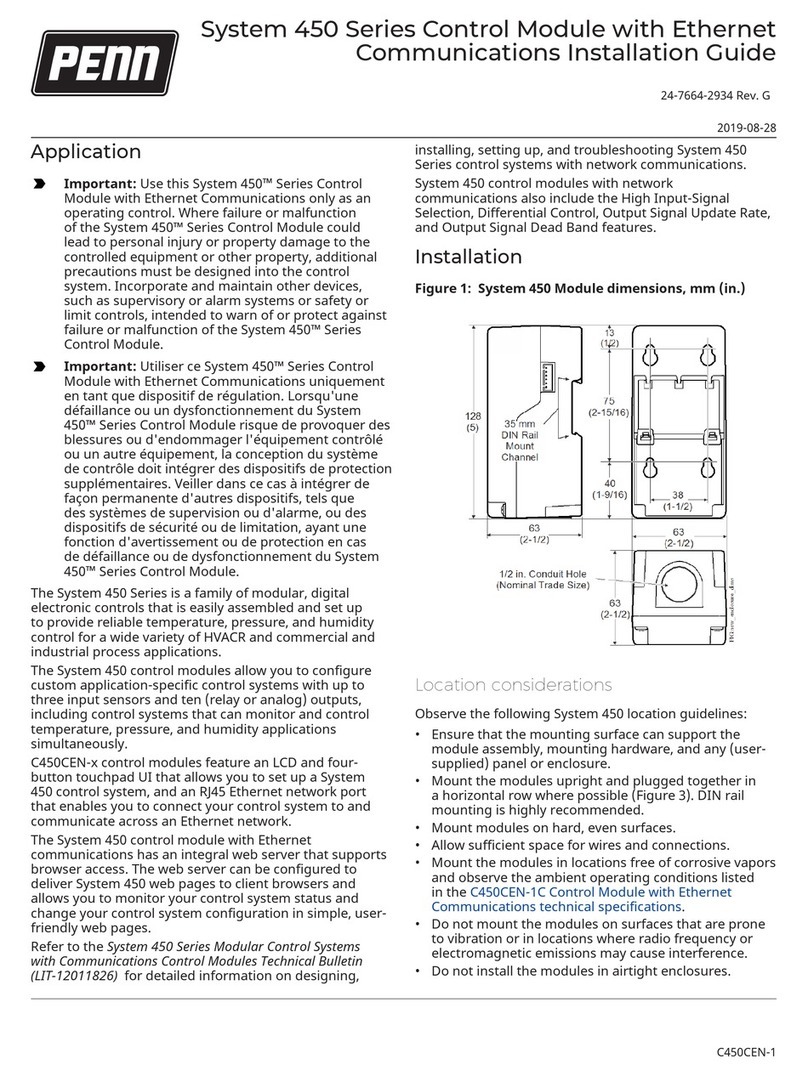

Observe the following guidelines when you locate and mount an A421 Control:

• Make sure that the mounting surface can support the control, DIN rail, mounting hardware, and

any user-supplied panel or enclosure.

• Mount the control in a vertical, upright orientation wherever possible. It is best practice to use

DIN rail mounting for type 1 controls.

• In direct-mount applications, mount the control on a flat and even surface.

• Mount the control in a location free of corrosive vapors and observe the ambient operating

conditions listed in Technical specifications for the A421 Control and the A99 sensor.

• Allow sufficient space to connect and route wires, view the LCD, and use the touchpad.

3A421 Series Electronic Temperature Controls with Off-Cycle Defrost Installation Guide