F783E Ex‐ia

Pg 3 00‐ISN‐203_Rev B

29/01/2021

CONTENTS

1. OPERATING INSTRUCTIONS ........................................................................................................................ 6

2. AUTHORISED USE ........................................................................................................................ 7

2.1 Export Restricons ......................................................................................................... 7

3. BASIC SAFETY INSTRUCTIONS ........................................................................................................................ 8

4. GENERAL INFORMATION ...................................................................................................................... 10

4.1. Contact address............................................................................................................ 10

4.2. Warranty ...................................................................................................................... 10

4.3. informaon on the internet ......................................................................................... 10

5. CERTIFICATION DETAILS [START OF CONTROLLED AREA]

5.1 IECEx ...................................................................................................................... 11

5.2 ATEX ...................................................................................................................... 11

5.3 Condions of Cerficate .............................................................................................. 12

[END OF CONTROLLED AREA]

6. SYSTEM DESCRIPTION ...................................................................................................................... 14

6.1. Intended applicaon area ............................................................................................14

6.2. General descripon ...................................................................................................... 14

6.3. Funcons/opons/designs........................................................................................... 15

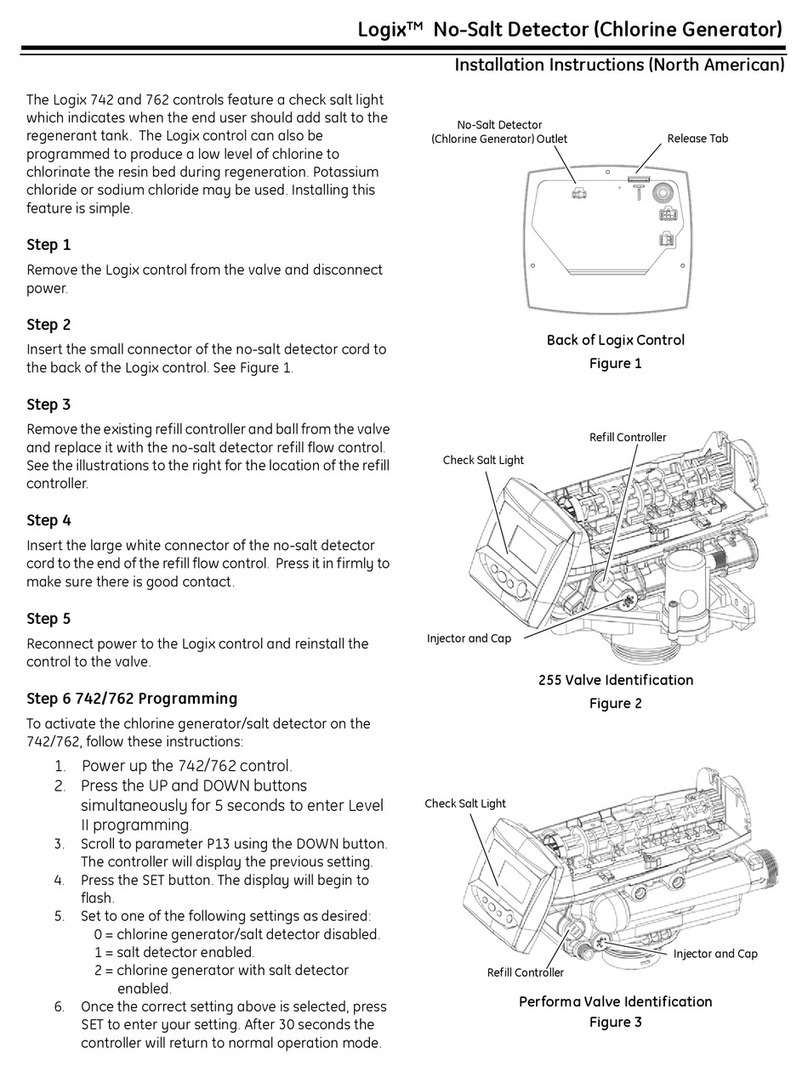

6.3.1 Structure of the control head ........................................................................... 15

6.3.2 Fluid diagram .................................................................................................... 16

6.3.3 Number of solenoid valves ............................................................................... 17

6.3.4 Pneumac interfaces ........................................................................................ 17

6.3.5 Manual control .................................................................................................17

6.3.6 Posion monitoring system.............................................................................. 17

7. TECHNICAL DATA ...................................................................................................................... 18

7.1. Operang condions.................................................................................................... 18

7.2. Conformity to the following standards ........................................................................ 18

7.3. Rang plate specificaons............................................................................................ 19

7.4. Pneumac data ............................................................................................................ 20

7.5. Posion system data .................................................................................................... 21

8. INSTALLATION ...................................................................................................................... 22

8.1. Safety instrucon ......................................................................................................... 22

8.2. Assembly of the control head ...................................................................................... 22

8.2.1. Mounng the base .......................................................................................... 22

8.2.1.1. Fing the control head—Linear actuator................................... 23

8.2.1.2. Limit Switch Seng ..................................................................... 23

8.2.1.3. Fing the control head—Rotary actuator.................................. 24

8.2.1.4. Limit Switch and Rotary Target Seng ....................................... 24

8.2.2. Pneumac and electrical connecons ............................................................... 24

9. OPENING AND CLOSING THE HOUSING ...................................................................................................... 27

9.1 Safety instrucons........................................................................................................ 27

9.2 Opening and closing the housing ................................................................................. 27

9.2.1 Opening the housing..................................................................................... 27

9.2.2 Closing the housing....................................................................................... 28