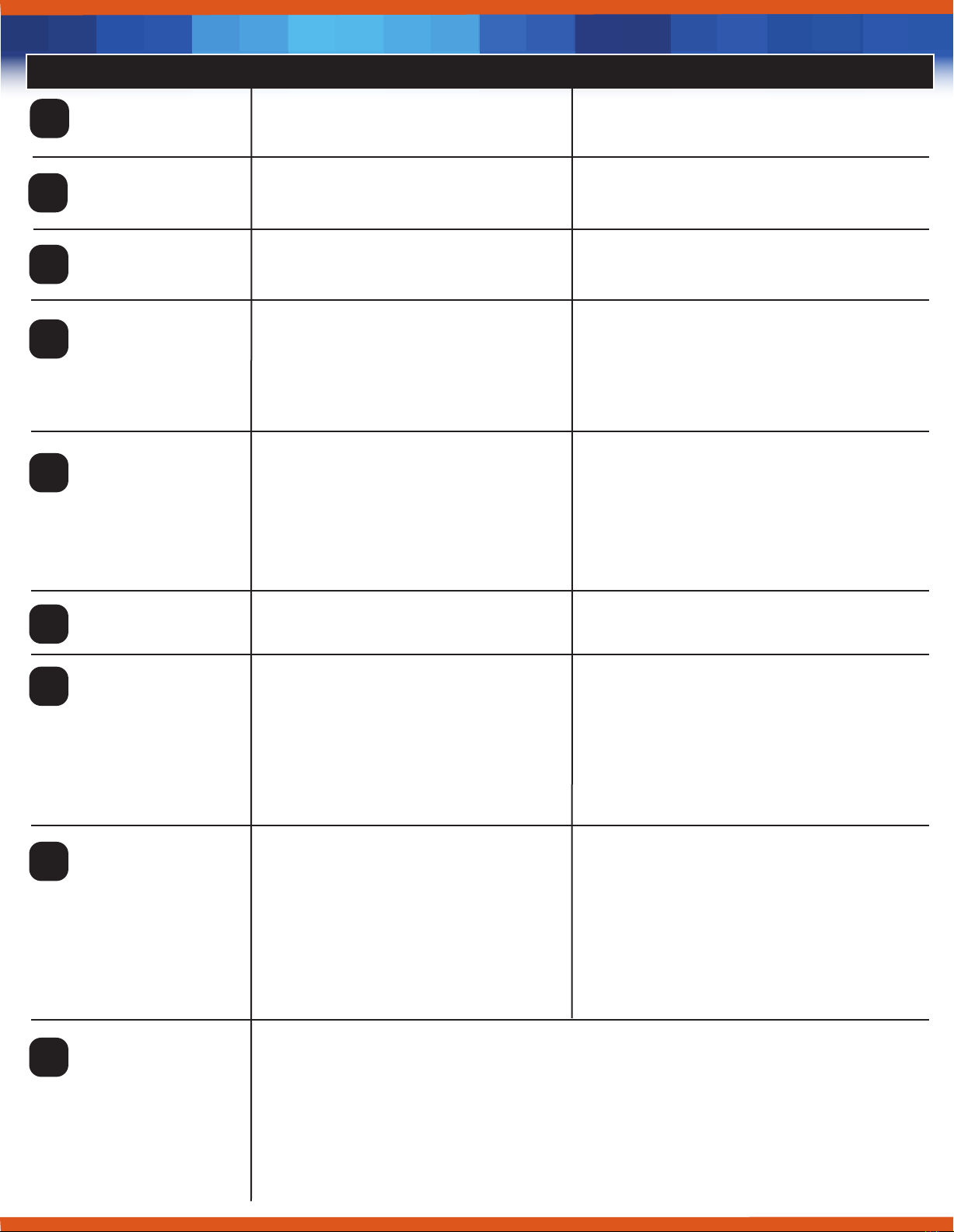

PROBLEM CAUSE CORRECTION

A) Fouled resin bed. A) Check backwash, brine draw and brine

tank fill. Increase frequency of regeneration.

Increase backwash time.

A) Faulty timer mechanism. A) Replace timer.

Iron in

conditioned water

6

A) Drain line flow control is plugged.

B) Injector is plugged.

C) Injector screen plugged.

D) Line pressure is too low.

E) Internal control leak.

A) Clean drain line flow control.

B) Clean or replace injectors.

C) Replace screen.

D) Increase line pressure (Line pressure must be

at least 20 PSI at all times).

E) Change seals, spacers and/or piston assembly.

Softener fails to

draw brine

8

A) Plugged drain line flow control. A) Clean flow control.

Excessive water

in brine tank

7a

Control cycles

continuously

9

A) Foreign material in control.

B) Internal control leak.

C) Control valve jammed in brine or

backwash position.

D) Timer motor stopped or jammed.

A) Remove piston assembly and inspect bore.

Remove foreign material and check control in

various regeneration positions.

B) Replace seals and/or piston assembly

C) Replace seals and/or piston assembly

D) Replace timer.

Drain flows

continuously

10

A) It is very common for the main and brine

pistons to need replacement after 5-10

years of use. The valve will get stuck

trying to complete a regeneration cycle.

Very often this occurs at the beginning of

the “brine rinse” cycle. The timer motor

may stop at this point also. The motors

are made to stop instead of forcing the

valve (which results in gear damage).

A) Replace the main piston and the brine piston

assembly. If the valve is on a chlorinated water

source or over 10 years old, it’s a good idea to

replace the main piston seals at the same time.

On rare occasions the timer motor may also

need to be replaced. Try the pistons replacement

first, this usually does the trick.

Piston Stuck in

Control Valve

11

A) There are a number of reasons why this can occur. To test if gears need replacement, remove

the meter dome, turn the cable by hand and observe the small white gears inside. You should

be able to make them turn with normal finger pressure. They should also continue to spin for

a moment after you stop applying pressure. If you cannot turn the white gear, you need to

replace the “meter cover”.

Most residential models use the standard range (0-21, i.e. 2,100 gallons) black plastic meter

cover and matching program wheel on the control. There is an extended range (0-55, i.e. 5,500

gallons) that is also available. Fleck also makes a brass 1” meter. This would only be found on

large commercial applications.

Gears inside the

metered dome

cover fail

12

A) Plugged injector system.

B) Timer not cycling.

C) Foreign material in brine valve.

D) Foreign material in brine line

flow control.

A) Clean injector and replace screen.

B) Replace timer.

C) Clean or replace brine valve.

D) Clean brine line flow control.

Salt water in

service line

7b

A) Air in water system. A) Assure that well system has proper air

eliminator control. Check for dry well condition.

Loss of resin

through drain line

5

Another problem that can occur with the Fleck 5600 Econominder (metered) valve. The gears inside the meter dome cover fail.

This can be due to a number of reasons.

The way to tell if this part needs replacement is to remove the meter dome, turn the cable attached by hand and observe the

small white gears inside. You should be able to make them turn with normal finger pressure. They should also continue to spin

for a brief moment after you stop applying pressure. If you cannot turn the white gear, you need to replace the “meter cover”.

Most residential models use the standard range (0-21, i.e. 2,100 gallons) black plastic meter cover and matching program wheel

on the control. There is an extended range (0-55, i.e. 5,500 gallons) that is also available. Fleck also makes a brass 1” meter.

This would only be found on large commercial applications.