All Pentair trademarks and logos are owned by Pentair, Inc. or its affiliates. All other registered and unregistered trademarks and logos are the property of their

respective owners. Because we are continuously improving our products and services, Pentair reserves the right to change specifications without prior notice.

Pentair is an equal opportunity employer.

© 2016 Pentair Filtration Solutions, LLC. All Rights Reserved.

WATER QUALITY SYSTEMS

EVERPURE-SHURFLO WORLD HEADQUARTERS, 1040 MUIRFIELD DRIVE, HANOVER PARK, IL 60133 USA • FOODSERVICE.PENTAIR.COM

800.942.1153 (US ONLY) • 630.307.3000 MAIN • 630.307.3030 FAX • CSEVERPURE@PENTAIR.COM EMAIL

EVERPURE-SHURFLO AUSTRALIA, 1-21 MONASH DRIVE, DANDENONG SOUTH, VIC 3175 AUSTRALIA

011.1300 576 190 TEL • 011.61.39.562.7237 FAX • AU.EVERPURE@PENTAIR.COM EMAIL

EVERPURE-SHURFLO CHINA, 21F CLOUD 9 PLAZA, NO 1118, SHANGHAI, 200052, CHINA

EVERPURE-SHURFLO INDIA, GREEN BOULEVARD, B-9/A, 7TH FLOOR - TOWER B SECTOR 62, NOIDA - 201301

91.120.419.9444 TEL • 91.120.419.9400 FAX • INDIACUSTOMER@PENTAIR.COM EMAIL

EVERPURE-SHURFLO EUROPE, PENTAIR WATER BELGIUM BVBA, INDUSTRIEPARK WOLFSTEE, TOEKOMSTLAAN 30, B-2200 HERENTALS, BELGIUM

+32.(0).14.283.504 TEL • +32.(0).14.283.505 FAX • SALES@EVERPURE-EUROPE.COM EMAIL

EVERPURE-SHURFLO JAPAN INC., HASHIMOTO MN BLDG. 7F, 3-25-1 HASHIMOTO, MIDORI-KU, SAGAMIHARA-SHI KANAGAWA 252-0143, JAPAN

81.(0)42.775.3011 TEL • 81.(0)42.775.3015 FAX • INFO@EVERPURE.CO.JP EMAIL

EVERPURE-SHURFLO SOUTHEAST ASIA, 390 HAVELOCK ROAD, #04-01 KING’S CENTRE, SINGAPORE 169662

65.6768.5800 TEL • 65.6737.5149 FAX • CSEVERPURE@PENTAIR.COM EMAIL

7012-55 Rev D NO16

INSTALLATION

The following instructions provide for installation of a QL2-OW2-Plus and QL2-OW4-Plus filter regardless of whether or not the

office water application is installed. The filter cartridge should be placed into the head after the system has been installed.

1. Install the QL2-OW2-Plus or QL2-OW4-Plus as close

to the application as possible. Do not connect this filter

to any other equipment. Connect only to the cold water

line and do not expose it to high temperatures.

2. Select a location for the filter (nominally 4" x 4" x 18"

long which includes a 21⁄2" drop-down for cartridge

changes). Write the installation date and anticipated

cartridge replacement date in the space provided

on the cartridge label. The OW2-Plus and OW4-Plus

cartridges should be replaced every six (6) months

or whenever flow of water becomes too slow for

convenience.

3. If required, shut off the incoming water supply and

relieve pressure in the tubing. Cut the tubing, allowing

a 4" space for the filter installation between the water

supply and the application water inlet.

4. Install compression fittings into each port of the head.

Use a good grade of pipe dope or teflon tape on the

body threads. Do not overtighten the fittings.

5. Slide compression nuts up the tubing (threads toward

tubing ends). Slide a ferrule onto each tubing end

(brass for copper tubing, plastic for plastic tubing).

Insert a tube insert into plastic tubing.

6. Position the QL2 head assembly so that the arrow

shown on top of the head corresponds to the direction

of water flow and attach the incoming cold water

supply to the inlet of the head.

7. Connect the filter outlet to the application water inlet

line.

8. Mount the head to the wall using the screws and star

washers provided.

9. Install the OW2-Plus or OW4-Plus cartridge into the

head following the instructions on the cartridge label.

10. Turn on the water and check for leaks.

NOTE: The OW2-Plus or OW4-Plus cartridges must be

flushed before use by running water through them at

maximum flow for ten (10) minutes to purge the cartridge of

air and establish precoat.

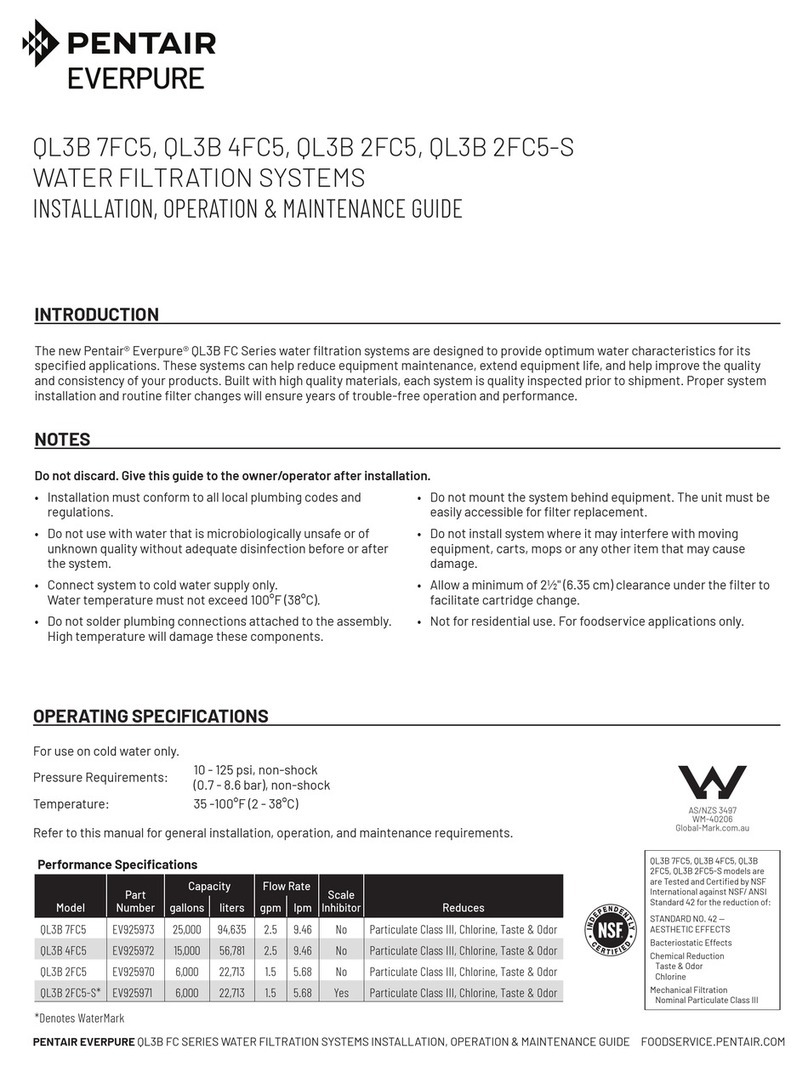

System Tested and Certified by NSF International against

NSF/ANSI Standard 42 and 53 for the reduction of:

STANDARD NO. 42 —

AESTHETIC EFFECTS

Chemical Reduction

Taste & Odor

Chlorine

Mechanical Filtration

Nominal Particulate Class I

STANDARD NO. 53 —

HEALTH EFFECTS

Chemical Reduction

Lead*

Mechanical Filtration

Cyst

Asbestos

(OW2-Plus only)

*Lead claim valid only with use of fitting with flow control at

0.5 gpm (p/n EV3081-32)