3"

"

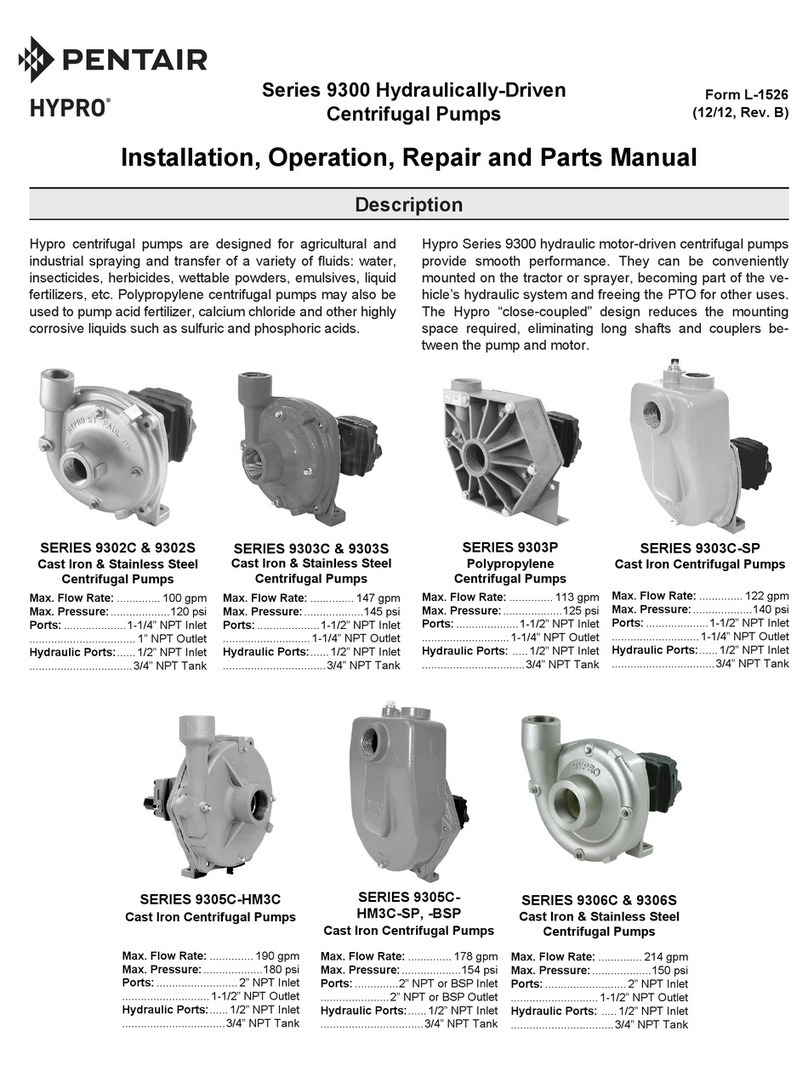

PRODUCT DESCRIPTION"

CONFIGURATION:

Pumps are offered with various Mechanical seal types

available.

•Type 1

•Type 21

•Type 8B2

Along with above mentioned configurations, pumps are also

offered with following options required and mentioned by

customer at the time of placing order.

•With or without Impeller wear rings

•With or without Flush line

•With or without Abrasive separator

PARTS:

Refer Exploded view, FIG. 11 for listing various parts

INSTALLATION

READ AND UNDERSTAND ALL SAFETY WARNINGS

AT THE BEGINNING OF THE MANUAL BEFORE

BEGINNING INSTALLATION OR ANY REPAIR

WORK.

PUMP LOCATION:

The pump should be located as close to the liquid source as

possible so that the suction line can be short and direct.

Location should require a minimum of elbows and fittings in

the discharge line to minimize friction losses. The pump must

be protected against flooding and located in a clean, open area,

where it is easily accessible for inspection, disassembly and

repair.

To minimize friction losses pump should be located such that

the use of elbows and fittings in the discharge line is reduced.

Pumps installed in dark, dirty areas or in cramped locations

are often neglected, which can result in premature failure of

both the pump and the driver. Open area would also be helpful

in better air flow into the motor and/or motor fan.

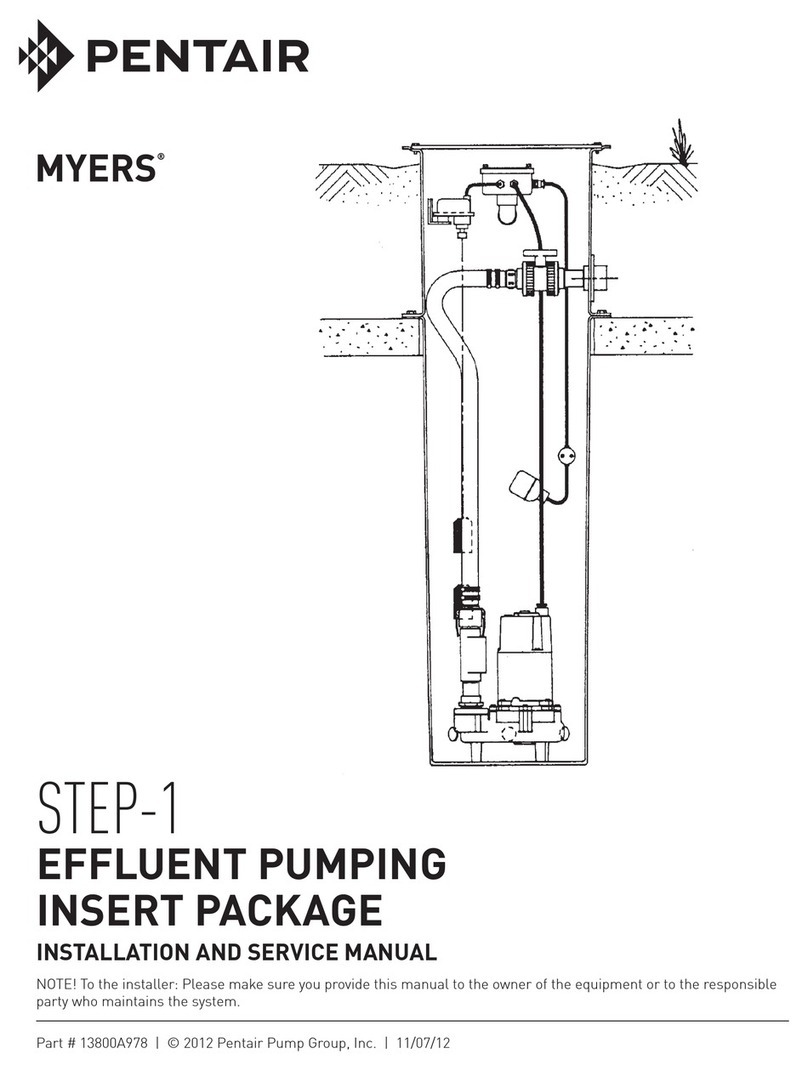

The 382 SC pump must be installed

vertically. Install isolating valves on

each side of pump so that pump

maintenance can be performed

without draining the system. Special

mounting requirements may be

required if the pump is to be

mounted near a noise or vibration

sensitive area. The installation must

be evaluated to ensure that the net

positive suction head available

(NPSHA) meets or exceeds the net FIG.1

positive suction head required (NPSHR), as stated by the

pump performance curve.

STORAGE & PROTECTION:

All pumps are shop serviced and delivered in a ready to

operate condition. If the pump after being delivered is not put

into immediate operation then proper care should be taken so

that it operates without failure when put into service. The

pump should be kept in a clean and dry area in a vertical

position. Ensure that the following precautions are taken for

pumps being stored for more than six months.

•Pump surfaces which are machined and unpainted (e.g.

flange ends, feet mounting etc.) and are easily subjected

to corrosion must be protected by corrosion resistant

coating.

•The pump shaft should be rotated once in a month to

avoid locking of rotating assembly. This would also be

helpful in uniform distribution of lubrication on bearings.

•Bearings must be lubricated with fresh lubricants when

pump is being put into service after a long time.

UNCRATING AND LIFTING:

Before shipment pump is fastened securely to the crate. The

pump should be removed from the crate carefully by using

proper tools and equipment. After removing from crate make

sure that all the components are in good condition and have

been received as mentioned in the packing list. Report

immediately to the concerned person/department if any

component is missing or received in a damaged condition.

Extreme care must be taken while handling the pump set.

Slings and hooks should be used in such a manner, so that

while lifting the pump is not exposed to stresses.

METHODOLOGY TO ORIENT PUMPS VERTICALLY

WHILE UNPACKING THE UNIT.

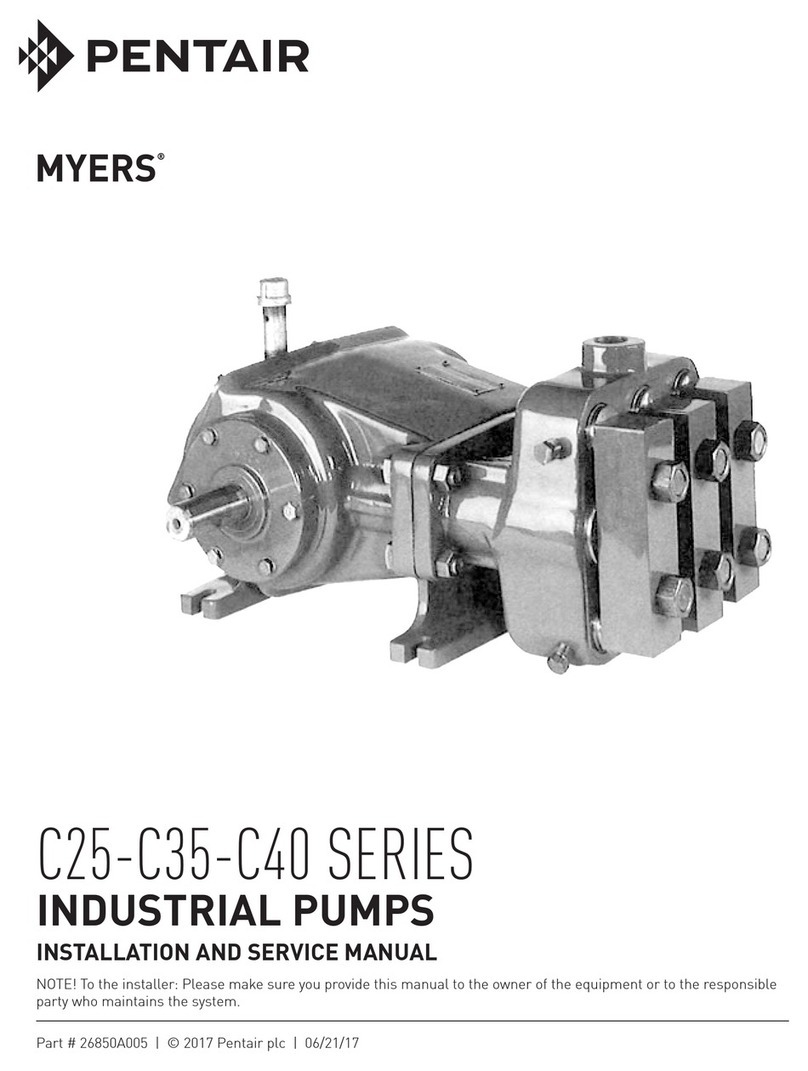

Since the pumps are shipped horizontally laid on crate (shown

in FIG.2). It is necessary to orient pumps vertically before

shifting to their installation location. Once the unit is

uncovered, lift the unit by placing straps around the motor

while making a pivot point of casing. Human effort will also

be required to orient the unit to vertical position. Now let the

unit to rest on crate and follow the procedure mentioned

below to place the unit to its desired location.

FIG. 2

NOTE:

For typical installation, suitable overhead lifting equipment of

adequate capacity to lift the driver, the entire pump (without

driver), or the heaviest sub assembly of the pump should be

available at the jobsite when installing or removing the pump.