Germany: +49 621 776 4411Pepperl+Fuchs Group

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

USA: +1 330 486 0001 Singapore: +65 6779 9091

fa-info@de.pepperl-fuchs.com

1

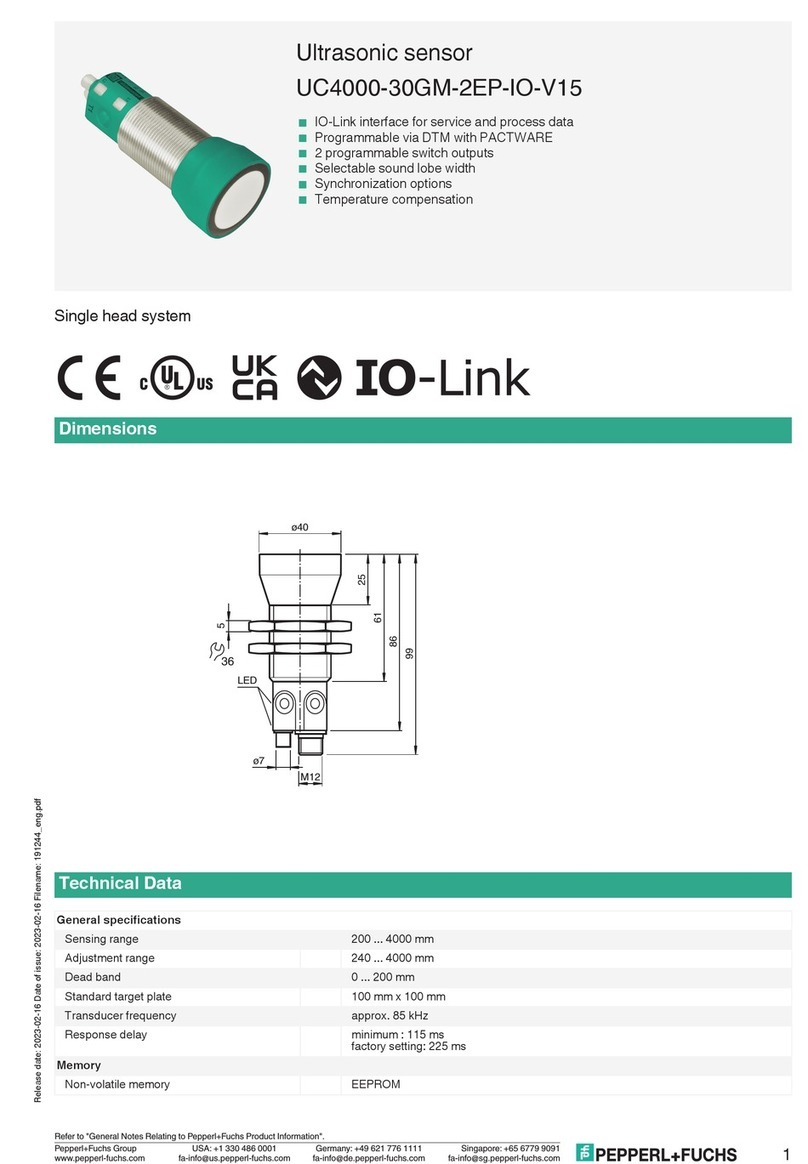

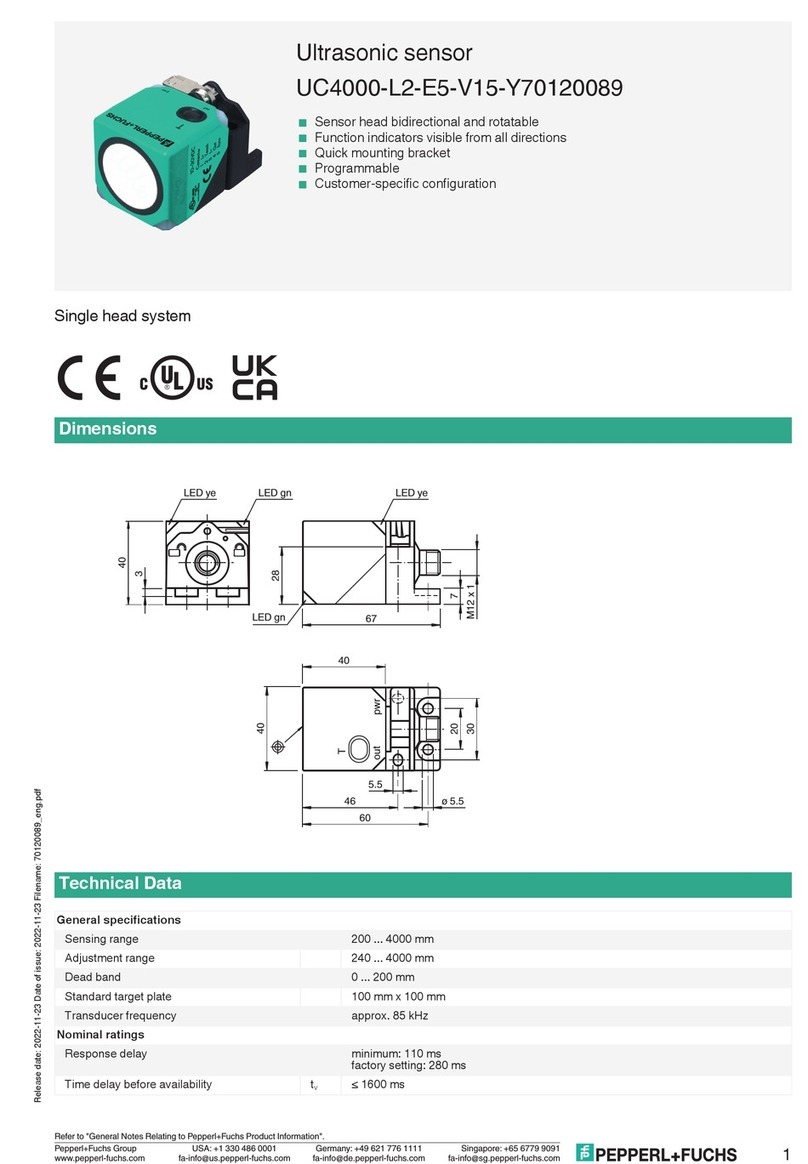

Ultrasonic sensor UC4000-L2M-E6-T-2M

Release date: 2018-10-25 11:49 Date of issue: 2018-10-25 299132_eng.xml

Technical data

General specifications

Sensing range 200 ... 4000 mm

Adjustment range 240 ... 4000 mm

Dead band 0 ... 200 mm

Standard target plate 100 mm x 100 mm

Transducer frequency approx. 85 kHz

Response delay minimum : 110 ms

factory setting: 280 ms

Indicators/operating means

LED green Operating display

LED yellow 1 switching state switch output 1

LED yellow 2 switching state switch output 2

LED red error

Electrical specifications

Operating voltage UB10 ... 30 V DC , ripple 10 %SS

No-load supply current I0≤50 mA

Interface

Interface type Serial interface (programming adapter required)

9600 BPS, no parity, 8 data bits, 1 stop bit

Input/Output

Input/output type 1 synchronization connection, bidirectional

0 Level 0 ... 1 V

1 Level 4 V ... UB

Input impedance > 12 kΩ

Output rated operating current < 12 mA

Pulse length 0.5 ... 300 ms (level 1)

Pulse interval ≥62.5 ms (level 0)

Synchronization frequency

Common mode operation ≤16 Hz

Multiplex operation ≤17 Hz / n , n = number of sensors , n ≤10

(factory setting: n = 5 )

Output

Output type 2 switch outputs PNP, NO/NC, programmable

Rated operating current Ie200 mA , short-circuit/overload protected

Voltage drop Ud≤2 V

Repeat accuracy ≤0.1 % of full-scale value

Switching frequency f ≤2.8 Hz

Range hysteresis H programmable , preset to 1 mm

Temperature influence < 1.5 % of full-scale value

Ambient conditions

Ambient temperature -40 ... 70 °C (-40 ... 158 °F)

Storage temperature -40 ... 85 °C (-40 ... 185 °F)

Mechanical specifications

Connection type cable , 5-pin

Degree of protection IP67

Material

Housing PA-GF35

Cable PUR

Transducer epoxy resin/hollow glass sphere mixture; polyurethane foam

Cable

Sheath diameter 7.25 mm

Bending radius > 37.3 mm , fixed

> 74.7 mm , moving

Core cross-section 5 x 0.82 mm2

Length L 2 m

Mass 355 g

Factory settings

Output 1 near switch point: 240 mm

far switch point: 4000 mm

output function: Window mode

output behavior: NO contact

Output 2 near switch point: 500 mm

far switch point: 2000 mm

output function: Window mode

output behavior: NO contact

Beam width wide

Evaluation procedure averaging (MxN)

M = 5

N = 2

General information

Supplementary information Switch settings of the external programming adapter:

"output load": pull-down

"output logic": inv

Compliance with standards and

directives

Standard conformity

Standards EN 60947-5-2:2007+A1:2012

IEC 60947-5-2:2007 + A1:2012

Approvals and certificates

CCC approval CCC approval / marking not required for products rated ≤36 V

Model Number

UC4000-L2M-E6-T-2M

Single head system

Features

• Extended temperature range

•Cableconnection

•Ruggedmetalbase

• Sensor head bidirectional and

rotatable

• Function indicators visible from all

directions

• Selectable sound lobe width

• Programmable

Diagrams

0 1000 2000 3000 4000 5000 6000

2000

1500

1000

500

0

-500

-1000

-1500

X

Y

Characteristic response curve

Distance X [mm]

Distance Y [mm]

flat surface 100 mm x 100 mm

round bar, Ø 25 mm

wide sound lobe

narrow sound lobe