Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

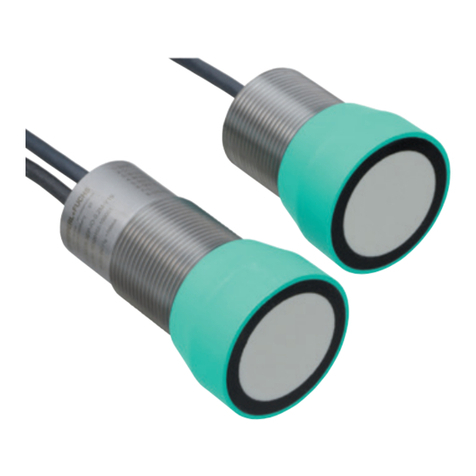

Ultrasonic sensor UC4000-L2-E5-V15

3

Release date: 2011-08-16 09:03 Date of issue: 2011-08-16 188207_eng.xml

- by applying the supply voltage 0 V or +UBto the Program input (only for programming the switch points)

- via the serial interface, which requires an external interface adapter

Procedures for programming via the sensor's Programming Button and the Program input are described below. For programming using the serial interface, please refer to the

software manual. Switch points and operating modes can be programmed independently without influencing each other

Note:

- Programming is enabled for 5 minutes after power-on. After 5 minutes without programming activity the programming feature will be locked.

- During any programming step it is possible to leave the programming routine without changing the sensor settings by pressing the Programming Button for 10 s.

Programming the Switch Points

Note:

If the red LED flashes during the programming procedure, it indicates uncertain target detection. In this case, please correct the target alignment until the yellow LED flashes.

The new settings will only be stored in the sensor’s memory if the yellow LED flashes.

Programming Switch Points using the Internal Programming Button

Programming the Near Switch Point

1. Place the target at the desired near switch point position

2. Press the Programming Button for 2 s (yellow LED flashes)

3. Press the Programming Button briefly (green LED flashes three times for confirmation). The sensor returns to normal operation.

Programming of the Far Switch Point

1. Place the target at the desired far switch point position

2. Press the Programming Button for 2 s (yellow LED flashes)

3. Press the Programming Button for 2 s (green LED flashes three times for confirmation). The sensor returns to normal operation.

Programming Switch Points by using the Program input wire

Notes:

- Before entering program mode the program input wire must be open circuit for at least 2s.

- If potential (0V or +UB) is applied for >10 s the sensor resumes normal operation without changing settings. To ensure successful programming, disconnect the Program

input before this 10 s time period elapses.

- If the program input is not used, the wire should be connected to 0 V.

- If programming adapter UB-PROG2 is used for the programming procedure, button A1 is assigned to 0 V and button A2 is assigned to +UB. Please make sure, that the

cordset’s wire, which is connected to the Program input is not connected (open circuit).

Programming the Near Switch Point

1. Place the target at the desired near switch point position

2. Apply 0 V to the Program input for 2 s (yellow LED flashes, then green LED flashes three times for confirmation). Then sensor returns to normal operation.

Programming the Far Switch Point

1. Place the target at the desired far switch point position

2. Apply +UBto the Program input for 2 s (yellow LED flashes, then green LED flashes three times for confirmation). Then sensor returns to normal operation.

Programming Modes of Operation

The sensor provides a three step routine to program the modes of operation. In this routine you can program:

1. Output function

2. Output behavior

3. Beam width

Programming the modes is carried out sequentially. To toggle from one mode to the next, press the Programming Button for 2 s.

Press the Programming Button for 5 s to enter the operating modes programming routine.

Programming the output function

1. The green LED flashes. The number of flashes indicates the current output function:

single flash: Switch point output function

double flash: Window output function

triple flash: Hysteresis output function.

2. Press the Programming Button briefly to toggle sequentially through these output functions and select the desired mode.

3. Press the Programming Button for 2 s to save and enter the programming routine for output behavior

Programming the output behavior

1. The yellow LED flashes. The number of flashes indicates the current output behavior:

single flash: Normally Open (NO)

double flash: Normally Closed (NC).

2. Press the Programming Button briefly to toggle sequentially through these output behaviors and select the desired mode.

3. Press the Programming Button for 2 s to save and enter the programming routine for beam width.

Programming the beam width

1. The red LED flashes. The number of flashes indicates the current beam width setting:

single flash: narrow

double flash: medium

triple flash: wide.

2. Press the Programming Button briefly to toggle sequentially through these beam shapes.

3. Press the Programming Button for 2 s to save and exit the operating modes programming routine.

Reset Sensor to Factory Settings

The sensor has a feature to reset to factory settings

1. Disconnect the sensor from power supply

2. Press and hold the Programming Button

3. Connect Sensor to power supply (yellow and red LED flash simultaneously for 5 s then yellow and green LED flash simultaneously)

4. Release Programming Button

The sensor now operates with default factory settings.