VisuNet EX2 GMP RM/PC 3700 Series

Safety

2018-07

7

1.4 Reference to Further Documentation

Observe laws, standards, and directives applicable to the intended use and the operating

location. Observe Directive 1999/92/EC in relation to hazardous areas.

The corresponding datasheets, manuals, declarations of conformity, EU-type examination

certificates, certificates, and control drawings if applicable (see datasheet) are an integral part

of this document. You can find this information under www.pepperl-fuchs.com.

Due to constant revisions, documentation is subject to permanent change. Please refer only to

the most up-to-date version, which can be found under www.pepperl-fuchs.com.

1.5 Mounting and Installation

Prior to mounting, installation, and commissioning of the device you should make yourself

familiar with the device and carefully read the instruction manual.

Do not mount the device at locations where an aggressive atmosphere may be present.

Do not mount a damaged or polluted device.

1.5.1 Device-Related Information

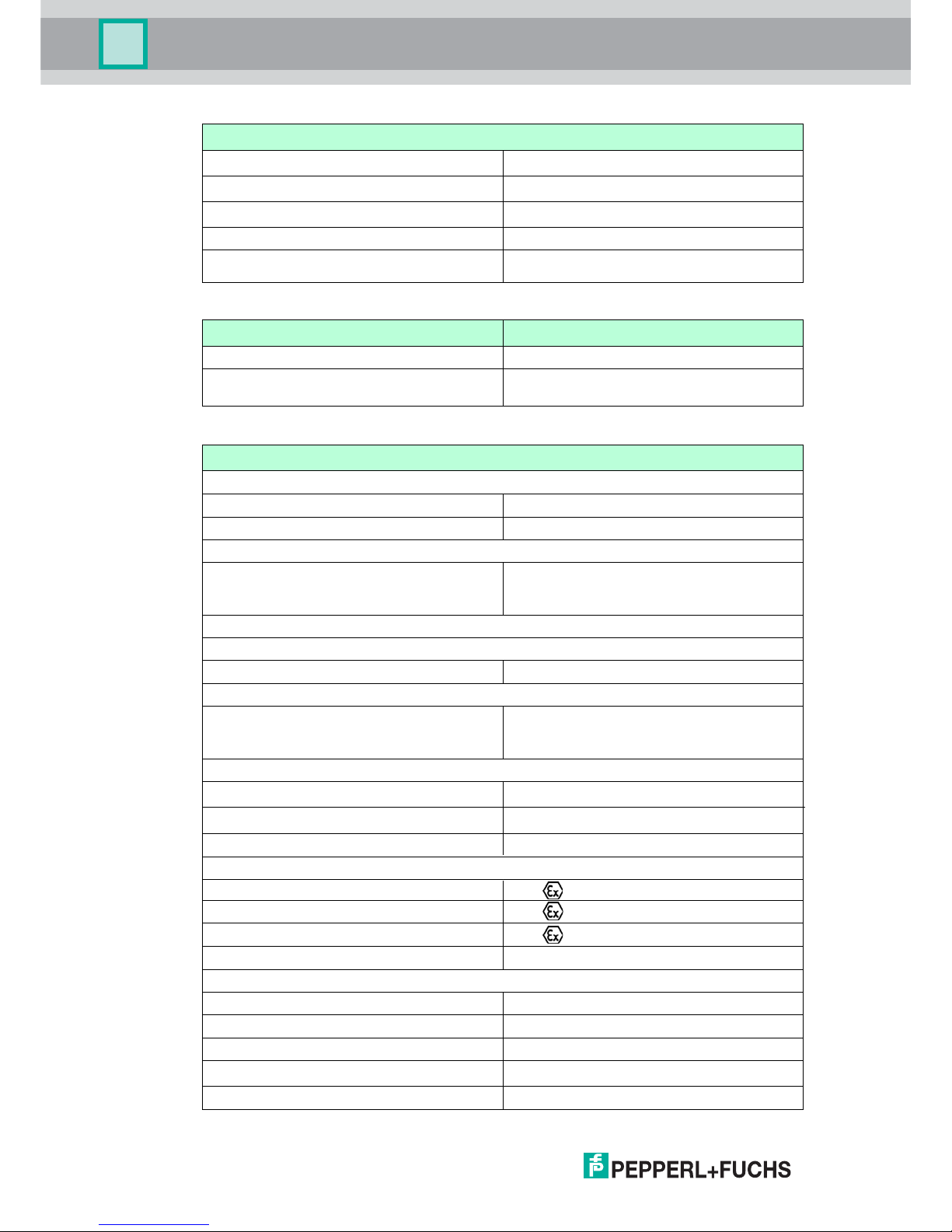

Tighten torque and wire diameter field wiring connection X1 ... X5

If cable glands are needed for installation, the following points must be considered:

■The cable glands used must be suitably certified for the application.

■The temperature range of the cable glands must be chosen according to the application.

■The cable glands fitted must not reduce the degree of protection.

1.5.2

The cables and connection lines must not be strained. Provide anadequate strain relief.

Unused cables and connection lines must beeither connected toterminals or securely tied

down andisolated.

Hazardous Area

If the device has already been operated ingeneral electrical installations, the device may

subsequently nolonger be installed in electrical installations used in combination with

hazardous areas.

Observe laws, standards, and directives applicable to the intended use and the operating

location. Observe Directive 1999/92/EC in relation to hazardous areas.

The housing has a ground connection. Connect tothis ground connection an equipotential

bonding conductor with a minimum cross section of 4 mm2.

Type of Protection

Type of Protection Exi

If circuits with type ofprotection Ex iareoperated with non-intrinsically safe circuits, they

must nolonger beused ascircuits with type ofprotection Ex i.

Te r m i n a l Torq ue / Nm Wire diameter mm2

Min. Max. Min. Max.

Te r m i n a l X 1 0,5 0,6 0,2 2,5

Terminal X2 ... X5 0,22 0,25 0,14 1,5