3.4 Accessories

The following products are available as accessories.

3.5 Further Information

Further product information and technical data are available at www.pepperl-

fuchs.com.

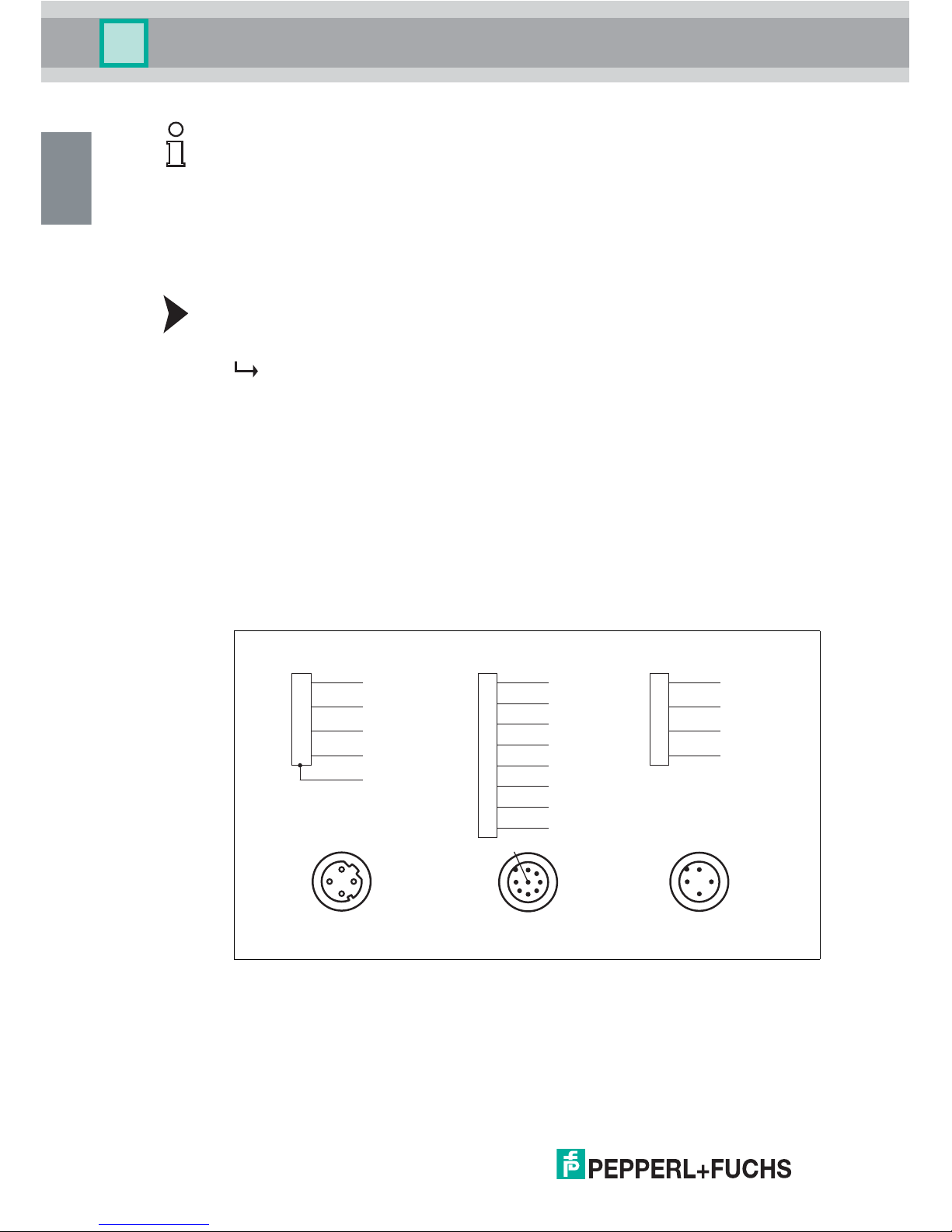

Designation Description

V1SD-G-2M-PUR-ABG-V45-G Patch cable M12 to RJ45, length 2 m

V1SD-G-5M-PUR-ABG-V45-G Patch cable M12 to RJ45, length 5 m

V1SD-G-ABG-PG9 Single-ended male cordset, M12 D-coded, 4-pin for bus cable

V1-G-2M-PUR Single-ended female cordset, straight, M12, 4-pin, PUR cable,

length 2 m

V1-G-5M-PUR Single-ended female cordset, straight, M12, 4-pin, PUR cable,

length 5 m

V1-W-2M-PUR Single-ended female cordset, angled, M12, 4-pin, PUR cable,

length 2 m

V17-G-2M-PUR Single-ended female cordset, straight, M12, 8-pin, shielded,

PUR cable, length 2 m

V17-G-5M-PUR Single-ended female cordset, straight, M12, 8-pin, shielded,

PUR cable, length 5 m

V1S-B Blind plugs

Note!

Installation Information for North America

If a connection is made with the M12 multi-pin connector, then in the final

installation of the power supply, the product must be used with a UL-listed

cable/connector assembly (CYJV) that is designed for at least 30 VDC and at least

1.0 A.

Designation Description

V1-G-BK-2M-PUR-U Single-ended female cordset, straight, M12, 4-pin, PUR cable, length 2 m,

"UL recognized"

V1-G-BK-5M-PUR-U Single-ended female cordset, straight, M12, 4-pin, PUR cable, length 5 m,

"UL recognized"

V1-G-BK-10M-PUR-U Single-ended female cordset, straight, M12, 4-pin, PUR cable, length 10 m,

"UL recognized"