1.3.General Warning Messages

WARNING!

Only operate the devices when assembled.

Do not clean the device in explosion-hazardous areas. Do not wipe it dry.

Switch o the device immediately if you believe that the device can no longer be

operated safely after damaging eects or abnormalities in general (ingress of

water, uids, exposure to temperatures outside the specied range etc.).

Note general statutory regulations or directives on occupational safety, accident

prevention regulations and environmental protection laws, e.g., Ordinance on

Industrial Safety and Health (BetrSichV).

Do not open the device.

You may not make any changes to the device.You may not exchange or replace

any components. Explosion protection is no longer guaranteed for non-speci-

ed components.

Ensure safe handling during use through adequate stability and freedom of

movement.

Immediately remove the device from the explosion-hazardous area in the event

of damage to the housing.

IEC 60079-19 and IEC 60079-17 stipulate that you as the operator of electrical

plants in explosion-hazardous areas are obligated to appoint an electrician to

check that these plants are in perfect condition.

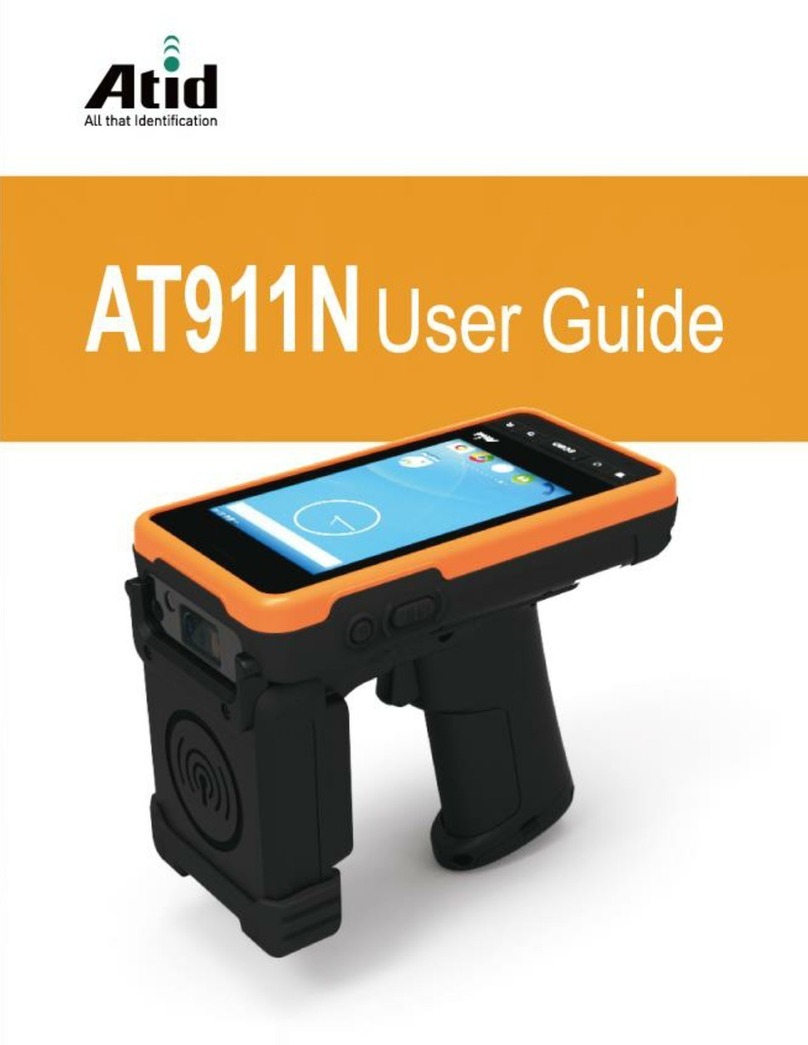

Do not insert any objects into the housing or other openings of the handheld

scanner. Openings on the device must not be obstructed, blocked, or covered.

Dispose of the device and the associated components correctly, as required by

law, by an approved company.

Note

Note the relevant deployment and operational regulations for electrical plants

(e.g., Directive 99/92/EC, Directive 2014/34/EU or the applicable national regula-

tions, IEC 60 079-14, and the series DIN VDE 0100).

As the operator, perform maintenance and repair work for the device properly in

explosion-hazardous areas.

9

ImporTanT noTes abouT The InsTruCTIon manual

2018-06