2

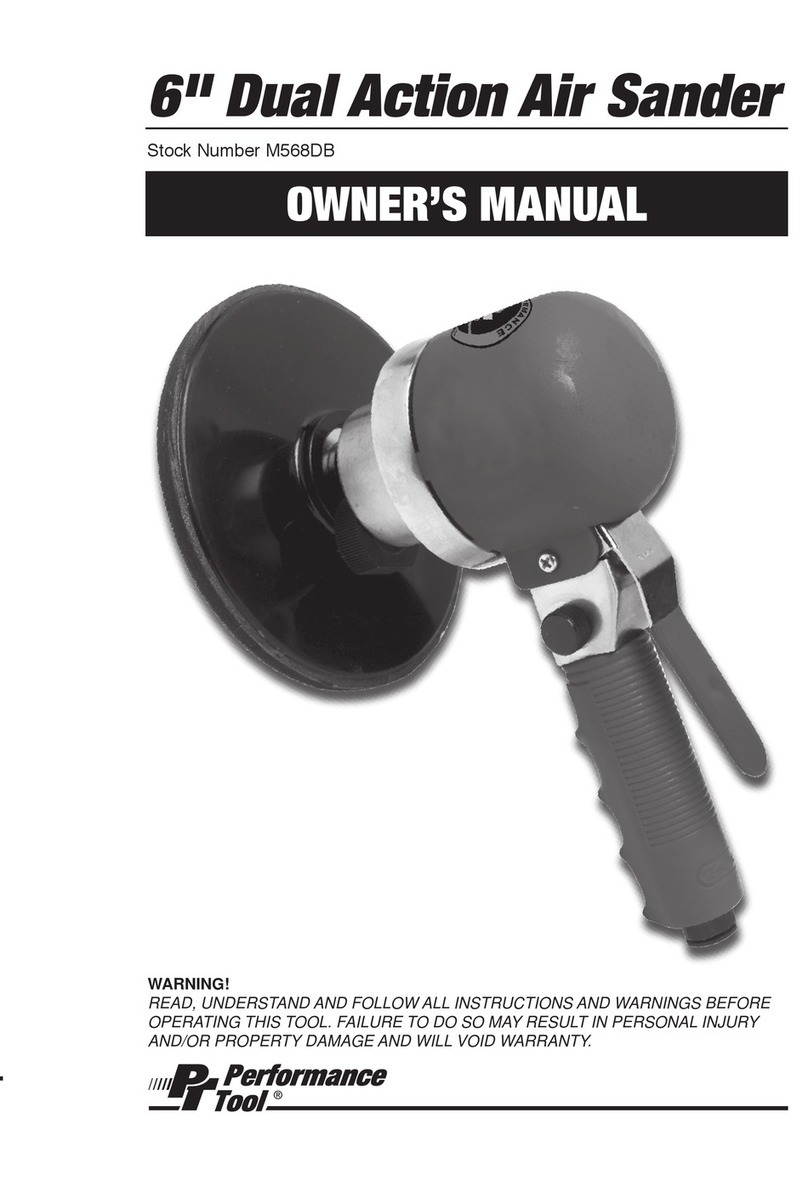

SPECIFICATIONS

Specifications are subject to change without notice

IMPORTANT SAFETY INFORMATION

WARNING!

READ, UNDERSTAND AND FOLLOW ALL INSTRUCTIONS AND WARNINGS

BEFORE OPERATING THIS TOOL. FAILURE TO DO SO MAY RESULT IN

PERSONAL INJURY AND/OR PROPERTY DAMAGE AND WILL VOID WARRANTY.

1. Use only paper sanding disks with the proper adhesive. Read, under stand

and follow all adhesive manufacturers’ directions. DO NOT USE CLOTH

BACKED SANDING DISKS WITH THIS TOOL.

2. Make sure sanding pad RPM rating matches Free Speed rating of this tool.

3. Wear a dust mask while operating this tool. Read, follow and understand

manufacturers instructions on paint, primer, paint preps, glazing, body filler,

etc. for additional respirator and ventilating requirements.

Warning! Some dust created by power sanding, sawing, grinding, drilling,

and other construction activities, contain chemicals known [to the State of

California] to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are: Lead from lead-based paints, Crystal-

line silica from bricks and cement or other masonry products, Arsenic and

chromium from chemically treated lumber.

Your risk from these exposures varies, depending on how often you do this

type of work. To reduce your exposure to these chemicals: work in a well

ventilated area, and work with approved safety equipment, such as those

dust masks that are specially designed to filter out microscopic particles.

4. Always use approved eye and ear protection when using air powered tools.

If raising dust/debris, wear a suitable mask. Do not wear loose clothing or

jewelry.

5. Always operate tool a safe distance from yourself and others in the work

area. Keep footing and balance at all times.

6.

Make sure work piece is secure to allow safe operation of the tool with both hands.

Do not hold the work piece in your hand, lap or against any part of your body.

Pad Size (IN)..........................................................................5

Sanding Surface (SQ.IN)..............................................50-200

Spindle/Thread Size...............................................5/16 in.-24

Max air pressure (PSI).........................................................90

Avg CFM ............................................................................4.2

Free Speed (RPM)........................................................18,000

Air Inlet (NPT).................................................................1/4 in.

Hose Size.......................................................................3/8 in.

Weight (LBS).......................................................................2.2

Warning!

Oil tool before each use. 4 to 5 drops of a good grade Air Tool Oil placed in the

air inlet is sufficient. Use proper air pressure and CFM rating listed for this tool.