3

Introduction

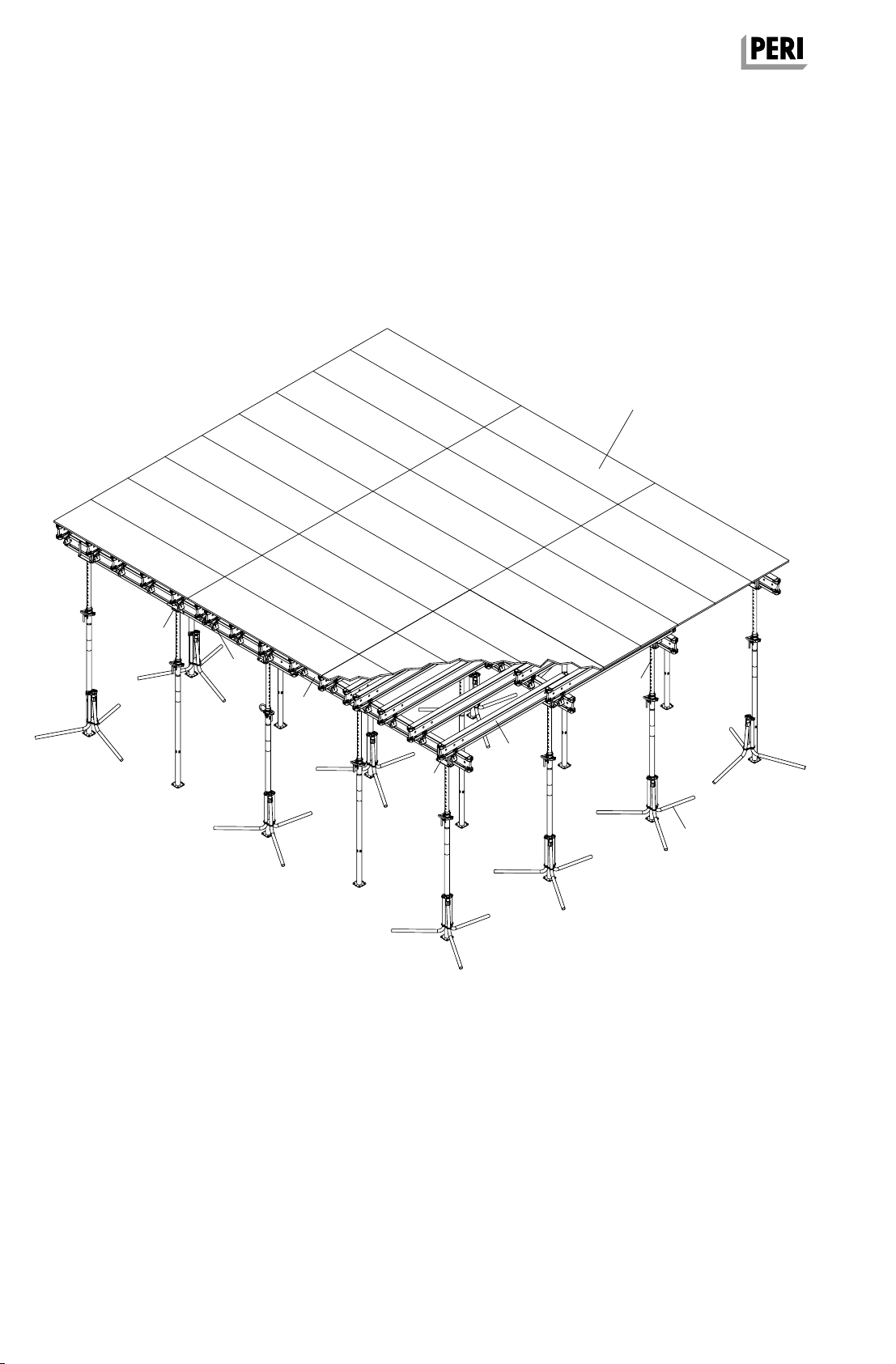

MULTIFLEX Girder Slab Formwork

Assembly Instructions for Standard Configuration

General

PERI products have been designed for

exclusive use in the industrial and com-

mercial sectors only by suitably trained

personnel.

These assembly instructions serve as

basis for the project-related risk assess-

ment and the instructions for the

provision and use of the system by the

contractor (user). However, they are

not intended to replace them.

Materials and working areas are to be

inspected on a regular basis especially

before each use and assembly, and

checked for signs of damage as well

as stability and functionality. Damaged

components must be exchanged

immediately on site and may no longer

be used.

Safety instructions and permissible

loads must be observed at all times.

Remove safety components only when

they are no longer required or if the

official representative of the contractor

gives instructions for this to take place.

For the application, inspection and repair

of our products, all current safety regula-

tions and guidelines must be observed

in the respective countries where they

are being used.

Storage and Transportation

Do not drop the components.

Store and transport components ensur-

ing that no unintentional change in their

position is possible. Detach lifting gears

from the lowered units only if they are in

a stable position and no unintentional

change is possible.

During the moving procedure, ensure

that components are picked up and set

down so that unintentional falling over,

falling apart, sliding or rolling is avoided.

Use only suitable load-carrying equip-

ment to move the components as well

as the designated load-bearing points.

During the moving procedure, always

use a guide rope.

Move components on clean, flat and

sufficiently load-bearing surfaces only.

Use original PERI storage and transport

systems, e.g. crate pallets, pallets or

stacking devices.

Safety Instructions

Components provided by the contractor

must conform with the characteristics

required in these assembly instructions

as well as with all valid construction

guidelines and standards. In particular,

the following applies if nothing else is

specified:

– timber components: Strength Class

C24 for Solid Wood according to

EN 338.

– scaffold tubes: galvanised steel

tubing with minimum dimensions

Ø 48.3 x 3.2 mm according to

EN 12811-1:2003 4.2.1.2.

– scaffold tube couplings according

to EN 74.

Deviations from the standard configura-

tion may only be carried out after a

separate risk assessment has been

completed by the contractor (user).

On this basis, appropriate measures for

the working safety and stability are to

be implemented.

The contractor must ensure that the

assembly instructions provided by PERI

are available at all times for the users

and must ensure they are also fully

understood.

During unfavourable weather conditions,

suitable precautions and measures are

to be implemented in order to guarantee

working safety and stability.

After exceptional events or long periods

of downtime whereby the formwork or

sub-structure was not used, the unit and

its components must be checked for

signs of damage as well as stability and

functionality.

The contractor (user) must ensure the

stability throughout all phases of con-

struction. He must ensure and verify

that all loads which occur are safely

transferred.

The contractor (user) has to provide safe

working areas for site personnel which

are to be reached through the provision

of safe access ways. Areas of risk must

be cordoned off and clearly marked.

Hatches and openings on accessible

working areas must be kept closed

during working operations.

The contractor must ensure that the

user fulfils the minimum requirements

for personal protective equipment, e.g.:

– Safety gloves,

– Safety helmet,

– Safety shoes,

– Safety goggles,

– PSAgA.

Residual Risks

The materials and components fully

complied with all valid safety regulations

at the time when they were first availa-

ble on the market. Nevertheless, a resid-

ual risk cannot be excluded even when

used as intended.

Possible residual risks and the resulting

dangers are described in the respective

chapter.