3Instructions for Assembly and Use – Standard Configuration

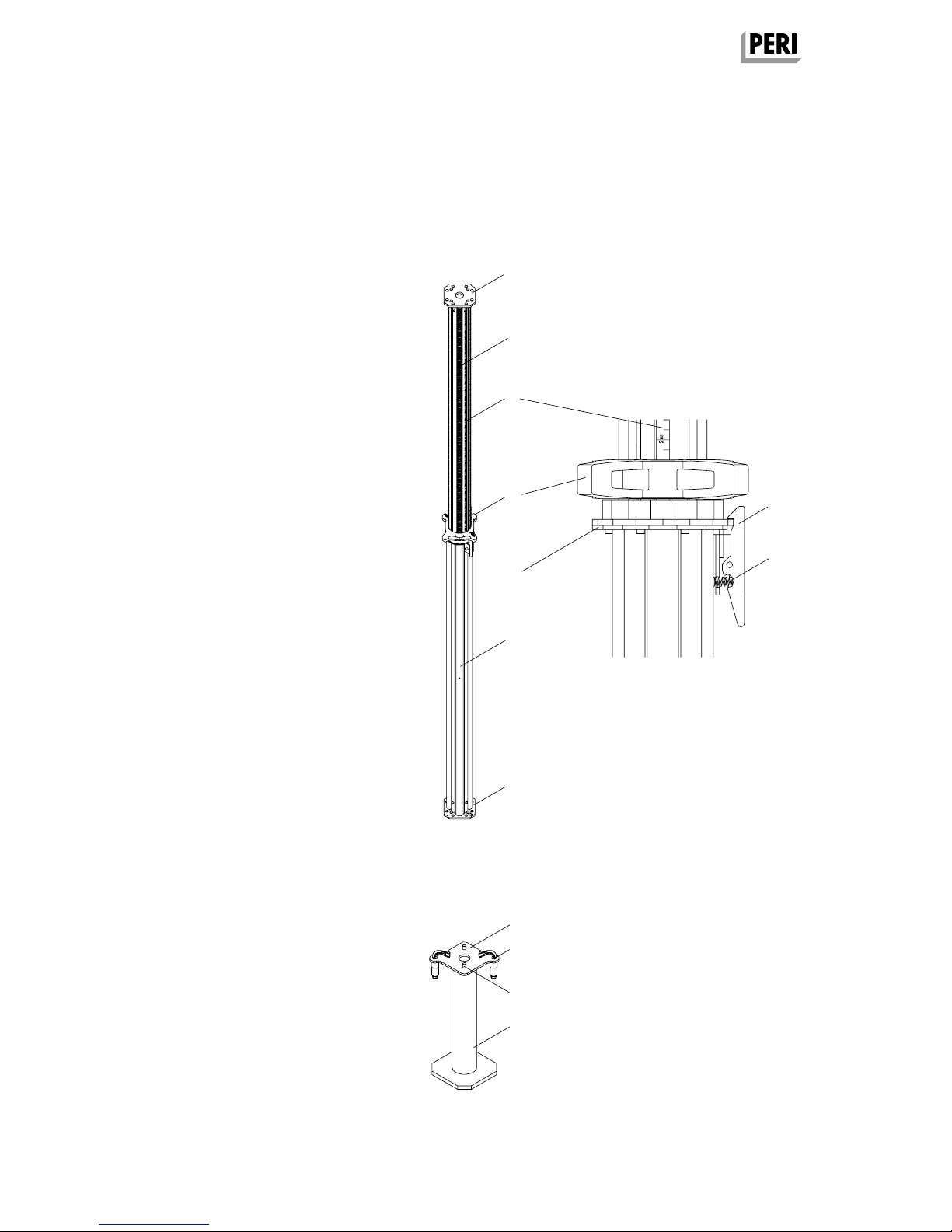

MULTIPROP Slab Props

Introduction

Safety instructions

Brochure:

– MULTIPROP Aluminium Slab Props

Type tests for:

– MULTIPROP Props

– MULTIPROP System

– MULTIPROP Props with Base MP 50

– MULTIPROP System with Base MP 50

General

1. Deviations from the standard configu-

ration and/or intended use present a

potential safety risk.

2. All country-specific laws, standards

and other safety regulations are to be

taken into account whenever our prod-

ucts are used.

3. During unfavourable weather condi-

tions, suitable precautions and meas-

ures are to be taken in order to ensure

both working safety and stability.

4. The contractor (user) must ensure

the stability throughout all phases of

construction. He must ensure and veri-

fy that all occuring loads are safely

transferred.

5. The contractor (user) has to provide

safe working areas for site personnel

which can be reached through the pro-

vision of safe access means. Areas of

risk must be cordoned off and marked.

Hatches and openings on accessible

working areas must be kept closed dur-

ing working operations.

6. For better comprehensibility, detailed

drawings are partly incomplete. The

safety installations which have possibly

not been included in these detailed

drawings must nevertheless still be

available.

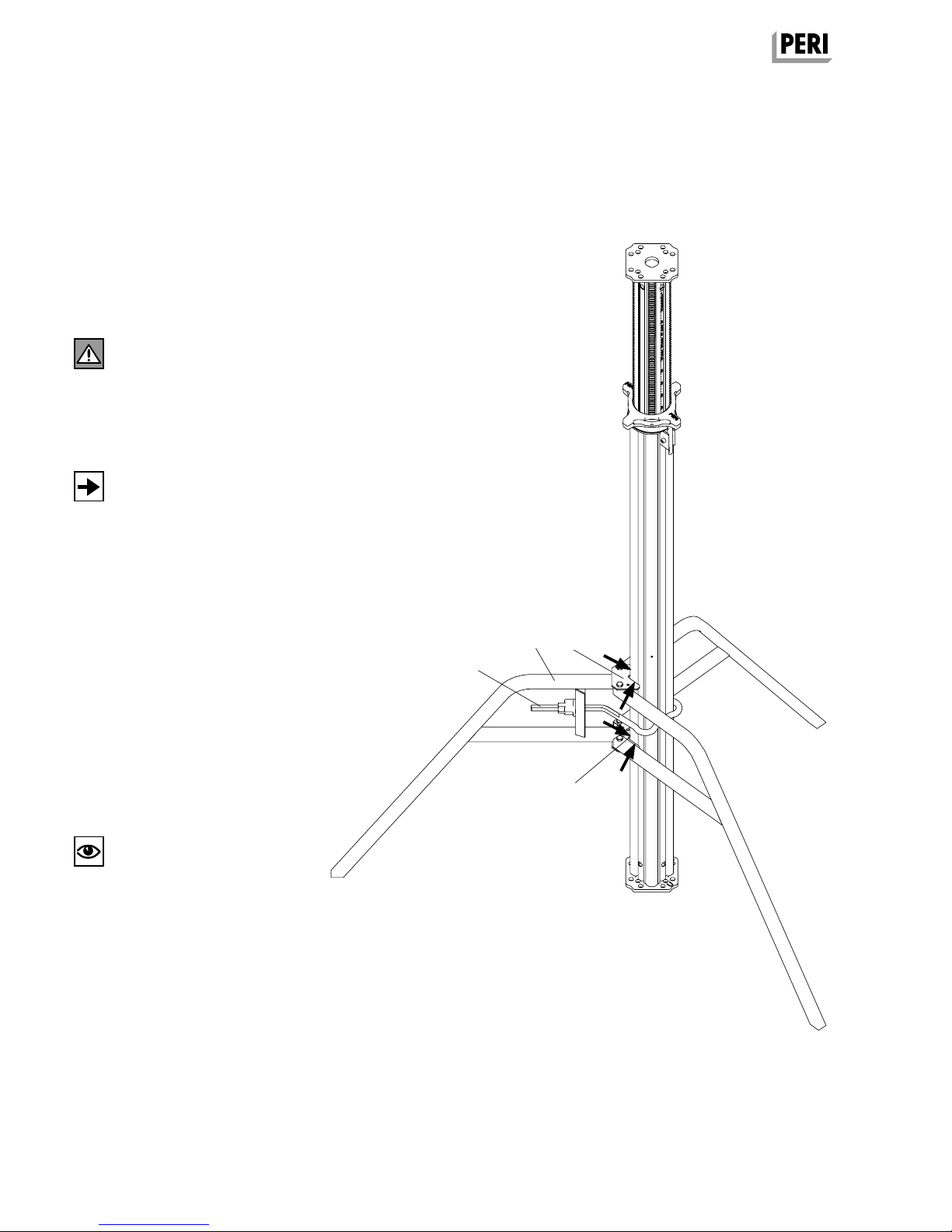

System-specific

1. Retract components only when the

concrete has sufficiently hardened and

the person in charge has given the

approval for striking to take place.

2. Anchoring is to take place only if the

anchorage has sufficient concrete

strength.

3. After exceptional occurrences or long

periods of downtime at the location

where the formwork or shoring is used,

the unit and its components must be

checked for stability and functionality.

Care and maintenance

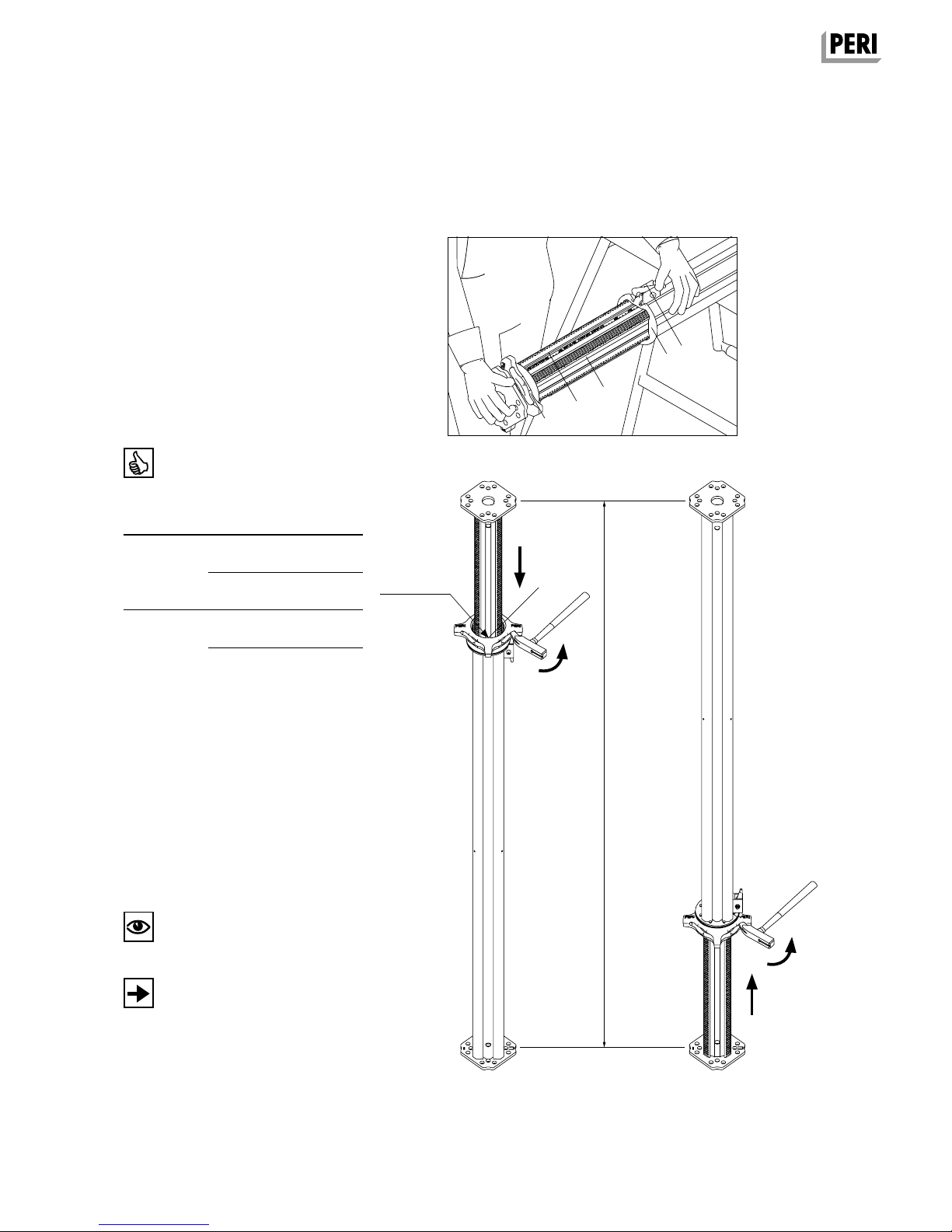

1. MULTIPROP Slab Props have been

designed for long-term use on the con-

struction site.

2. In order to maintain the value and

operational readiness of the MULTIPROP

Slab Props over a long period of time,

the props should be carefully handled at

all times.

3. Occasionally grease the rubbing plate

to ensure easier handling.

4. Only PERI qualified personnel are

allowed to carry out repairs on the

MULTIPROP Slab Props.

Storage and transportation

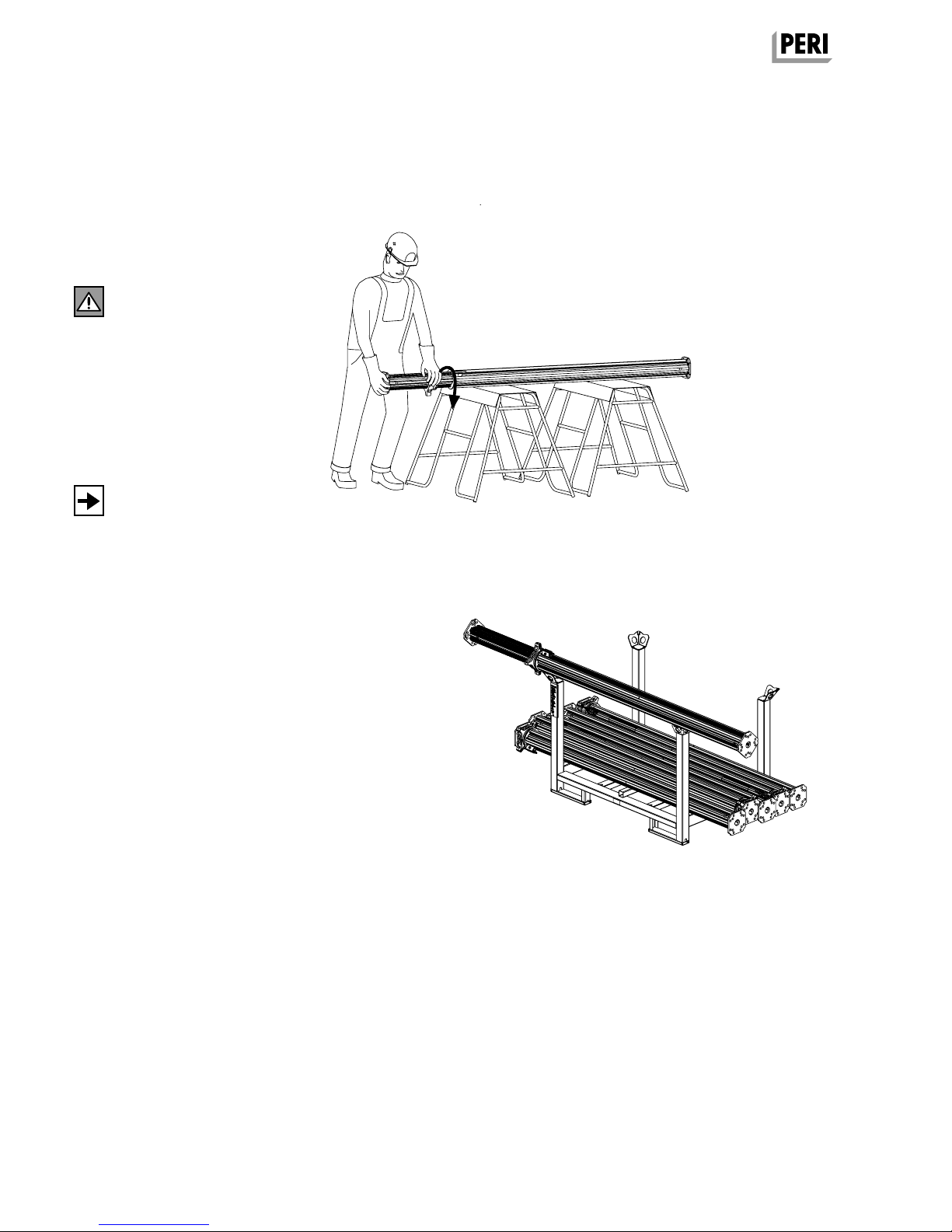

1. Do not drop the components.

2. Store and transport components

ensuring that no unintentional change

in their position is possible. Detach lift-

ing gear from the lowered units only if

these are in a stable position and no

unintentional change is possible.

3. When moving the components,

make sure they are lifted and set down

in a way that any unintentional tilting

over, falling apart, sliding or rolling away

is prevented.

4. Use only suitable load-carrying

equipment to move the components as

well as the designated load-bearing

points.

5. During the lifting and moving proce-

dure, ensure that all loose parts are

removed or secured.

6. Assemble and move components on

clean, flat and sufficiently load-bearing

surfaces only.

General

The structures shown in these Instruc-

tions for Assembly and Use are exam-

ples and feature only one component

size.They are valid accordingly for all

component sizes contained in the

standard configuration.

Instructions for Use:

– Pallets and Stacking Devices

Instructions for Assembly and Use:

– MULTIFLEX

– SKYDECK

– TABLE MODULES / SLAB TABLES

– SKYTABLE

– VARIODECK

Additional PERI product information

PERI design tables

EX_AuV_MULTIPROP_MP_Deckenstutzen.indb 3 24.03.16 15:10