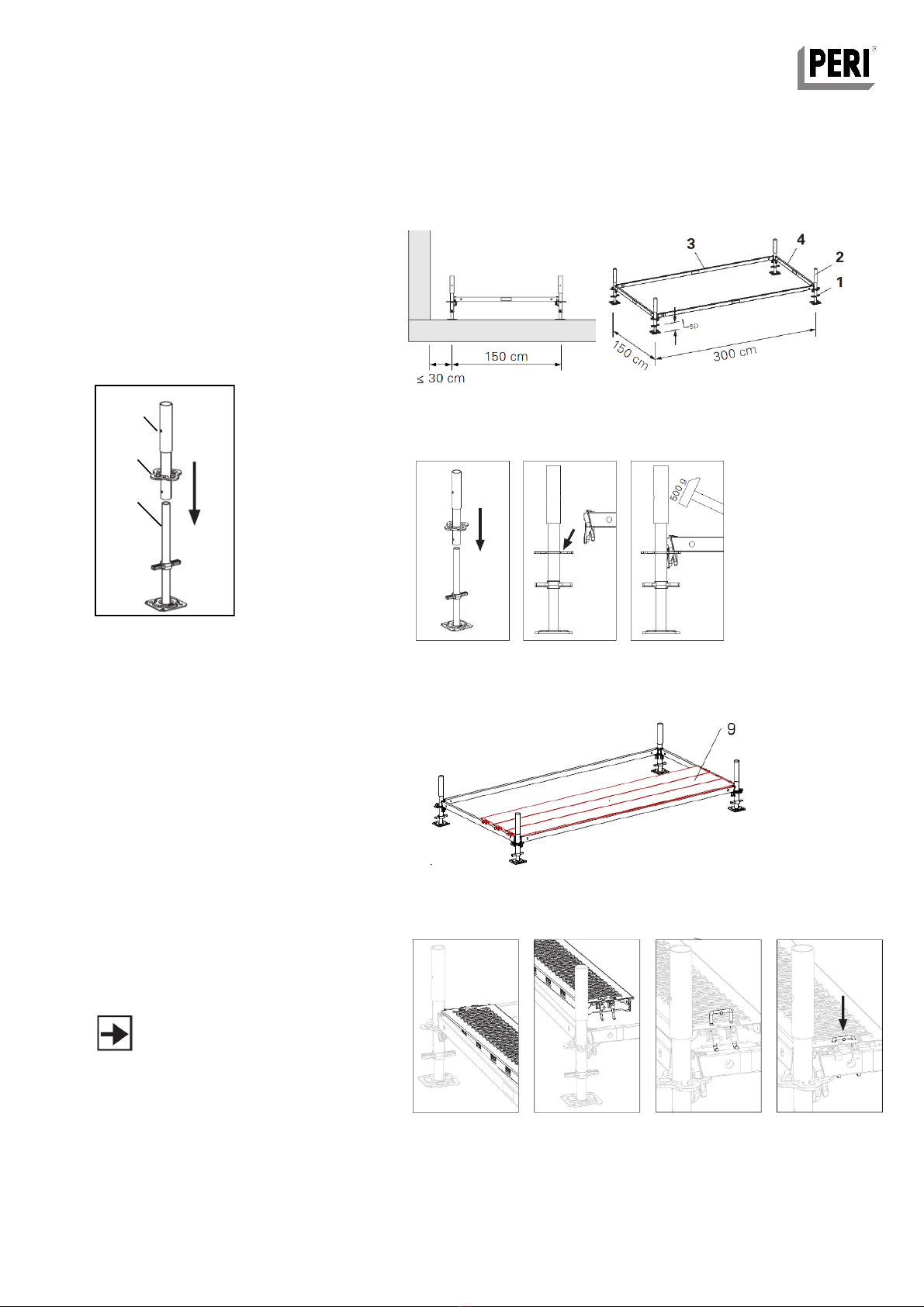

Always begin erecting at the highest

point, preferably at an internal corner.

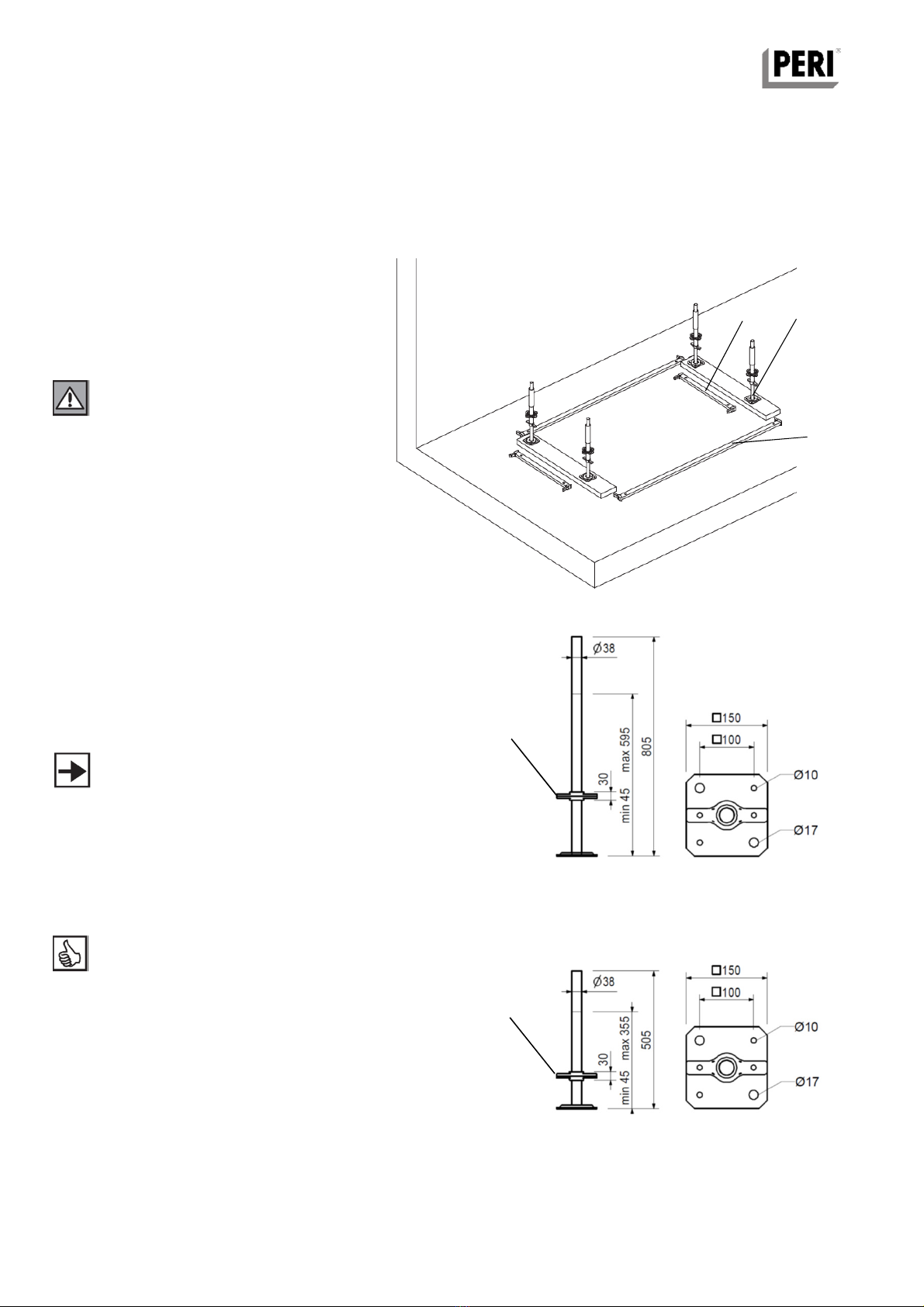

A1.1 Load distributing base area

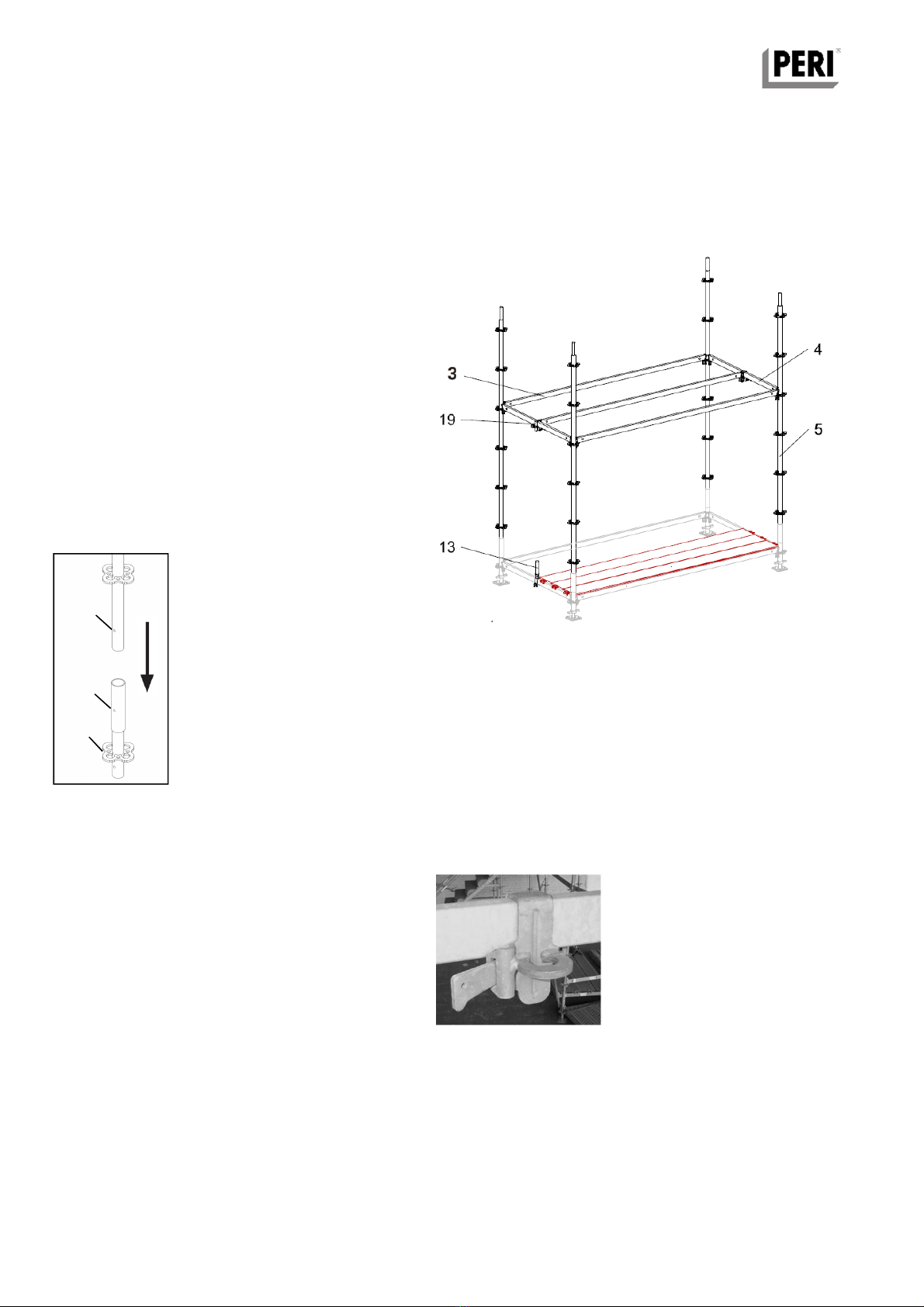

recting the scaffold must follow the

sequence described below!

Settlement must be avoided! The

scaffold must onl be erected on

suitable distribution plates on ground

or structure capable of withstanding

all imposed loads!

Lay the Ledgers UH 300 (3) and Ledgers

UH 150 (4) down to determine the length of

the surface to be scaffolded. This will fix

the distance between the Adjustable Base

Plates UJB (1)

A1.2 Adjustable Base Plates UJB

Position Adjustable Base Plates (1) at the

ends of the Ledgers UH 300 Plus (3) &

Ledgers UH 150 (4).

A1.3 Changes in base level

Steps, slopes and changes in level can be

accommodated using adjustment of the

Adjustable Base Plates / Base Spindles.

UJB 38-80/55

Yellow handle

Base Spindles TR 38-70/50, without

coloured handles, may be used instead of

Adjustable Base Plates UJB (1). xtension

range = 47mm – 535mm to top of collar

handle.

Adjustable Base Plates UJB 38-50/30 with

red handles have a maximum extension of

355mm to top of collar handle. Adjustable

Base Plates UJB 38-80/55 with yellow

handles have a maximum extension of 595

mm. to top of collar handle. Check with

P RI for suitability of use.

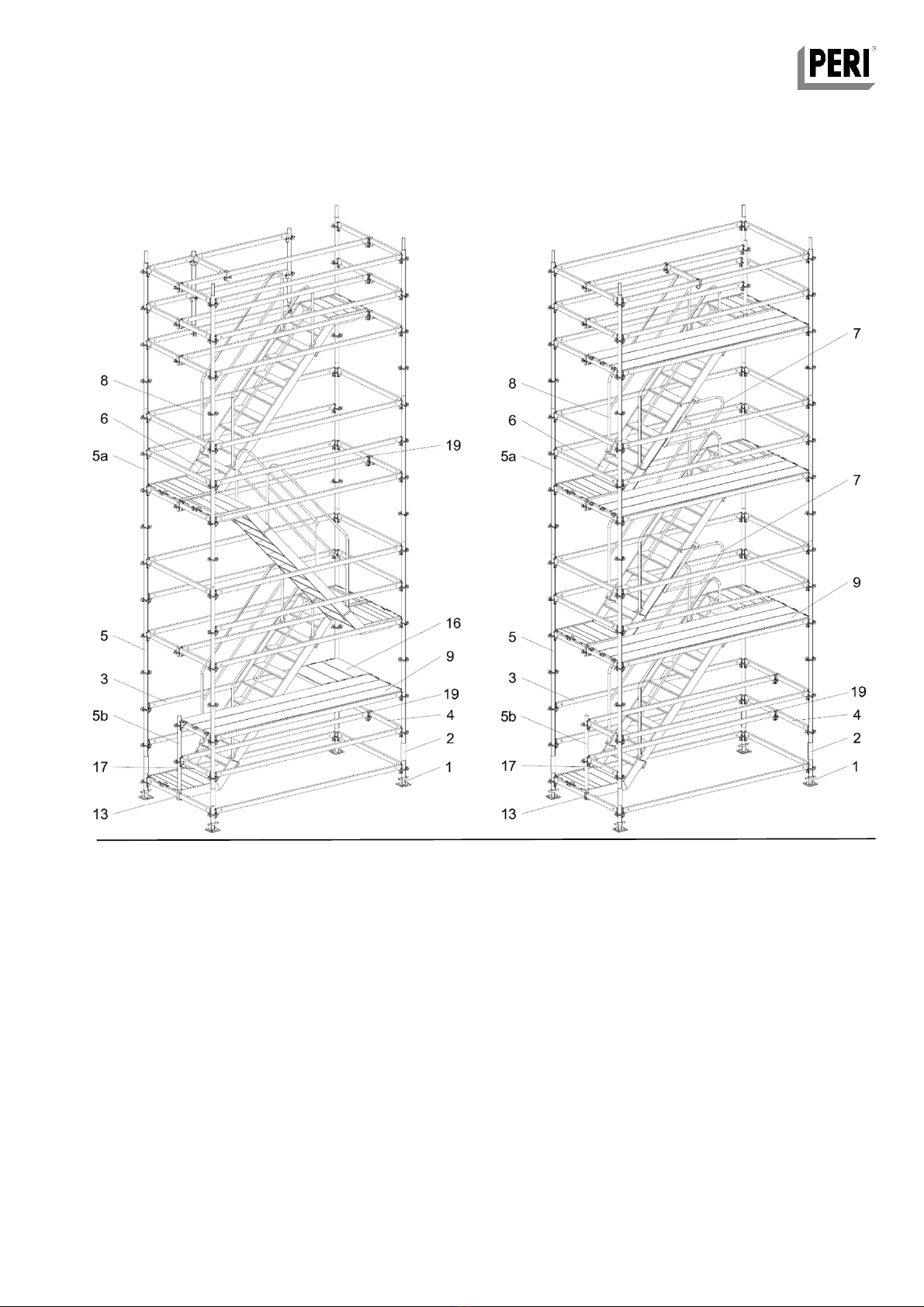

A – Assembly and Dismantling – Alternating

A1 Assembling the base

UJB 38-50/30

Red handle

Fig.A1-2

Fig.A1-3

5

Fig.A1-1

1

3

4

PERI UP Flex Stairs 75

Instructions for Assembly and Dismantling – Short lift system to SG4:15