Preface 6

P/N CLS155336 Rev. A FlexDrop iQ Automation Guide PerkinElmer, Inc.

Table of Contents

Preface ................................................................................................................................. 2

Copyright ......................................................................................................................... 2

Trademarks...................................................................................................................... 2

Content............................................................................................................................ 2

Proper Equipment Operation............................................................................................. 2

Contact Us....................................................................................................................... 3

Product Service and Customer Support Plans ................................................................... 3

Training for Your Product.................................................................................................. 3

FCC................................................................................................................................. 3

CE ................................................................................................................................... 4

Table of Symbols.............................................................................................................. 4

Introduction.......................................................................................................................... 7

Overview.......................................................................................................................... 7

Establishing Remote Access............................................................................................... 8

Getting Started................................................................................................................. 8

Running the Applications .................................................................................................. 9

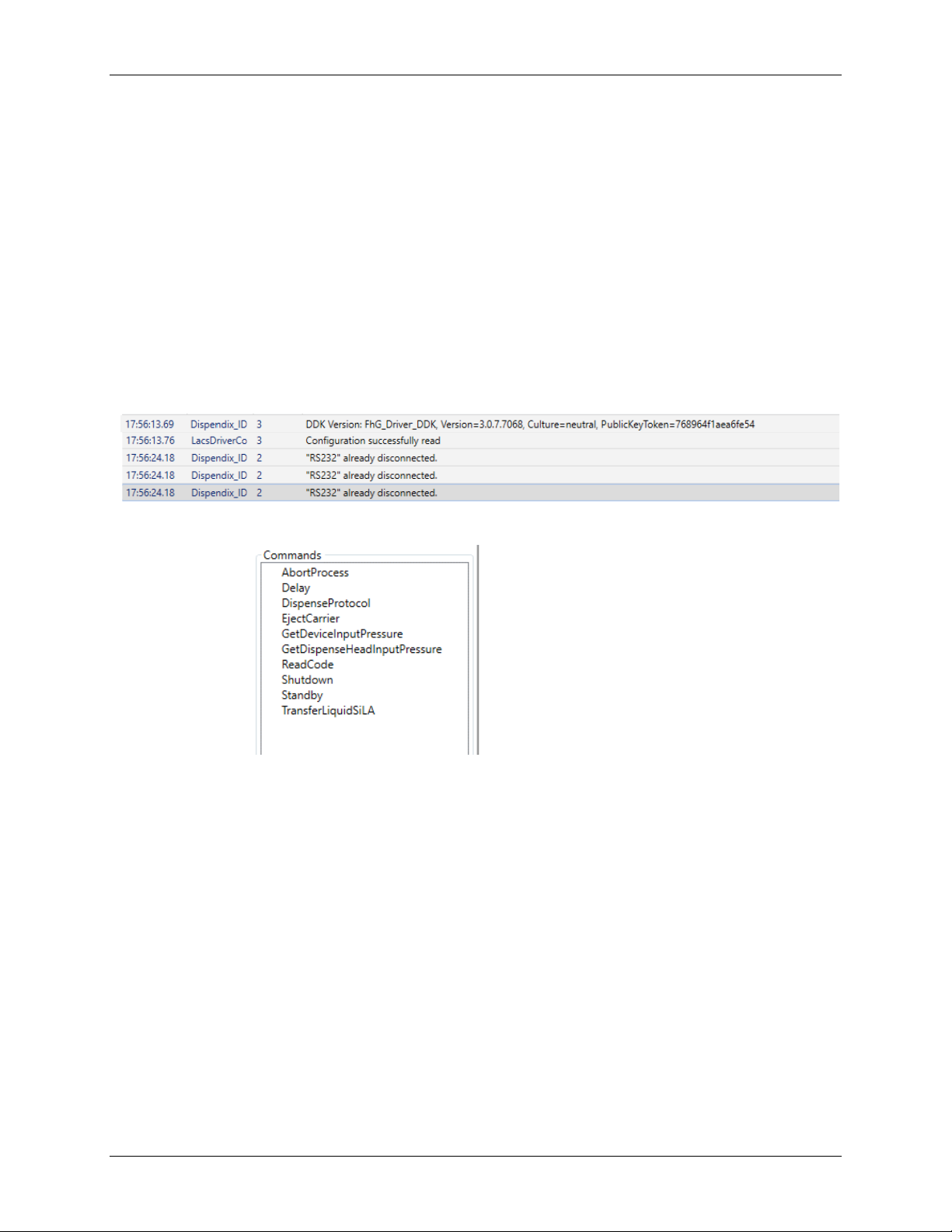

LacsDriverCore........................................................................................................... 9

Control via local CLI - LacsDriverCore Execution Mode.................................................... 10

Troubleshooting ............................................................................................................. 13

Device Initialization............................................................................................................ 15

SiLA Specification .......................................................................................................... 15

Initialization Example...................................................................................................... 16

Troubleshooting ............................................................................................................. 17

Running an Automation..................................................................................................... 18

Scheduling Example....................................................................................................... 18

Troubleshooting ............................................................................................................. 19

Implemented SiLA Command ............................................................................................ 20

EjectCarrier.................................................................................................................... 20

GetStatus....................................................................................................................... 20

Standby ......................................................................................................................... 21

DispenseProtocol ........................................................................................................... 22

Error Behavior .......................................................................................................... 22

TransferLiquidSiLA......................................................................................................... 23

AbortProcess ................................................................................................................. 24

Shutdown....................................................................................................................... 25

ReadCode...................................................................................................................... 25

Delay ............................................................................................................................. 25

Configure....................................................................................................................... 25

GetDeviceIdentification................................................................................................... 26

SetParameters ............................................................................................................... 26

GetDeviceInputPressure................................................................................................. 27

GetDispenseHeadInputPressure..................................................................................... 27

Lock/Unlock Device........................................................................................................ 28

The SiLA Communication Principle................................................................................... 29