3

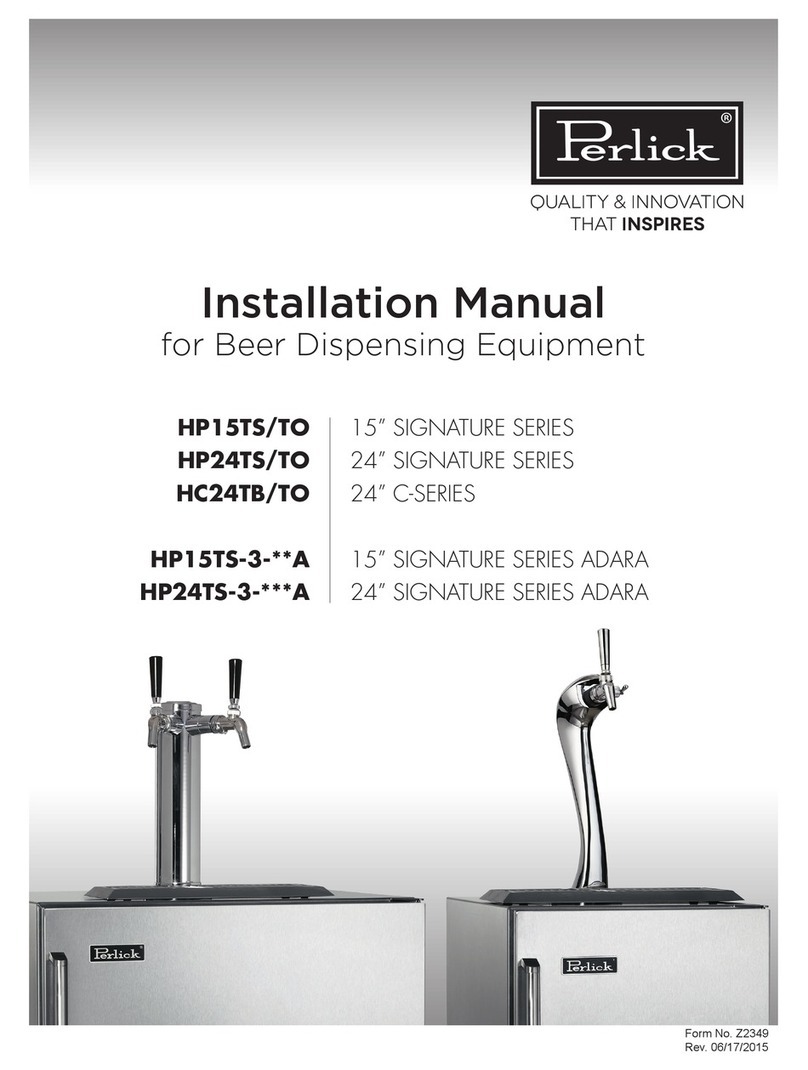

Operation & Installation Manual

Signature Series Beer Dispensers (HP15, HP24 and HP48 models)

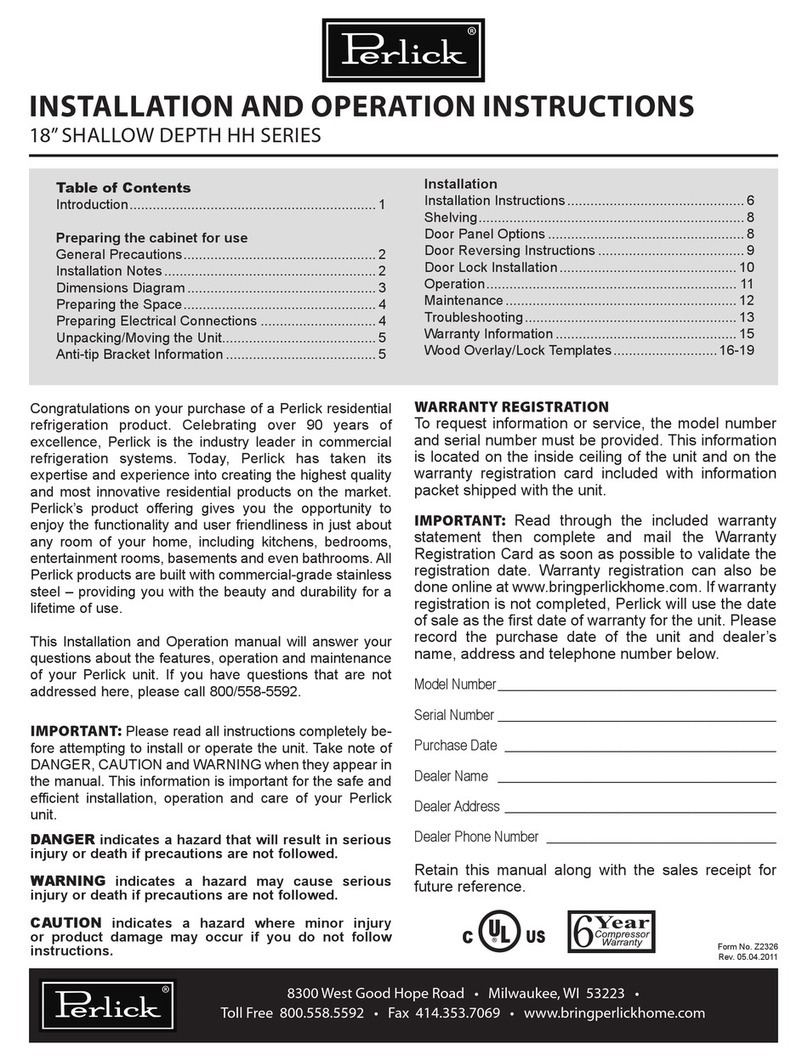

INTRODUCTION

Congratulations on your purchase of a Perlick residential

refrigeration product. Perlick has taken its expertise and experience

into creating the highest quality and most innovative residential

products on the market. Perlick’s product oering gives you the

opportunity to enjoy the functionality and user friendliness in

just about any room of your home, including kitchens, bedrooms,

entertainment rooms, basements and even bathrooms. All Perlick

products are built with commercial-grade stainless steel – providing

you with the beauty and durability for a lifetime of use.

This Installation and Operation Manual will answer your questions

about the features, operation and maintenance of your Refrigerated

Cabinet model. If you have questions that are not addressed here,

call 800 558-5592.

IMPORTANT : PLEASE READ all instructions completely before

attempting to install or operate the unit. First, as you follow these

Installation and Operation instructions, take particular note of the

DANGER!, CAUTION! and WARNING! symbols when they appear.

This information is important for the safe and ecient installation,

operation and care of your Perlick unit.

DANGER

Indicates a hazard that will result in serious injury or death if

precautions are not followed.

WARNING

Indicates a hazard may cause serious injury or death if

precautions are not followed.

CAUTION

Indicates a hazard where minor injury or product damage may

occur if you do not follow instructions.

Once the unit is completely installed, we suggest you keep this

manual and purchasing documentation in a safe place for future

reference. Should problems occur: refer to the troubleshooting

section of this manual. The information will help you quickly identify

a problem and get it remedied. In the event you require assistance,

please contact the dealer where you purchased your unit.

WARRANTY REGISTRATION CARD

To request information or service, the model number and serial

number must be provided. This information is located on the inside

ceiling of the unit and on the warranty registration card included

with information packet shipped with the unit.

IMPORTANT : Read through the included warranty statement

then complete and mail the Warranty Registration Card as

soon as possible to validate the registration date. Warranty

registration can also be done online at www.perlick.com. If

warranty registration is not completed, Perlick will use the date

of sale as the rst date of warranty for the unit. Please record the

purchase date of the unit and the dealer’s name, address and

telephone number below.

MODEL NUMBER: ____________________________________

SERIAL NUMBER: ____________________________________

PURCHASE DATE: ___________________________________

DEALER NAME & ADDRESS:

__________________________________________________

__________________________________________________

__________________________________________________

DEALER PHONE: ____________________________________

Table of Contents

Introduction ..........................................................................................................3

Warranty Registration ..................................................................................... 3

General Precautions .........................................................................................4

Installation Specications .............................................................................4

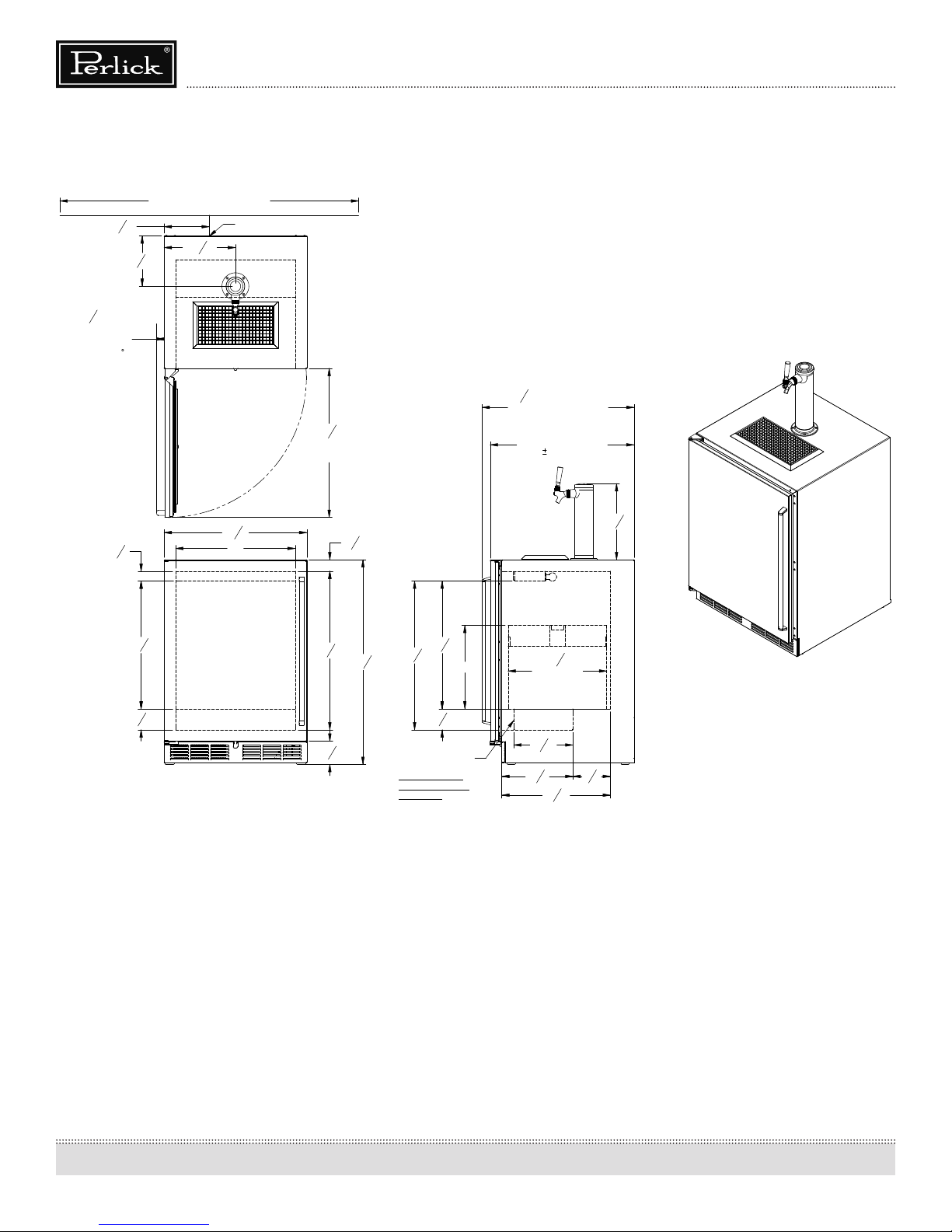

Overall Dimensions and Drawings ......................................................... 5

Preparing the Space ........................................................................................8

Preparing the Electrical Connections ...................................................8

Unpacking and Moving .................................................................................8

Anti-tip Brackets ................................................................................................. 9

Installation .............................................................................................................10

Shelving ................................................................................................................... 11

Toe Plate Wood Overlay Drawings..........................................................12

Shelf and Drawer Removal ..........................................................................14

Door Options and Wood Overlay Installation ..................................15

Operation ............................................................................................................... 24

General .................................................................................................................24

Temperature Controller ..............................................................................25

Unit Temperatures/Product Temperature ......................................26

Cleaning and Maintenance ......................................................................... 26

Installing Tapping Equipment ...................................................................27

Mounting Hole Template for Draft Arms ............................................30

CO2 Connections .............................................................................................. 31

Tapping a Keg ......................................................................................................32

Cleaning the Beer System ............................................................................33

Pouring the Perfect Glass of Beer ............................................................34

Troubleshooting .................................................................................................35

Warranty ..................................................................................................................37