Table of contents

1 Overview.............................................................................. 7

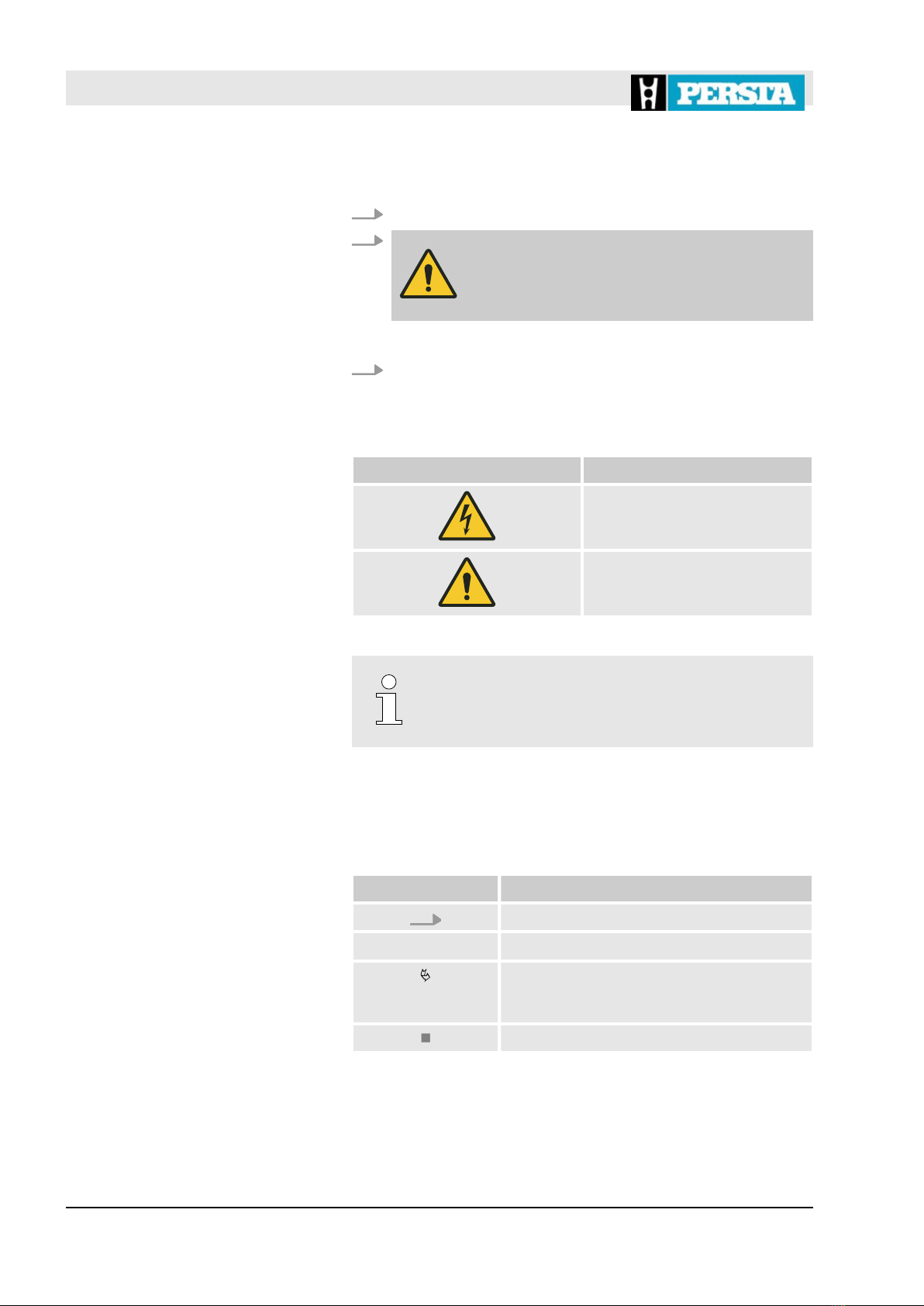

2 Safety................................................................................... 9

2.1 Symbols in this manual................................................. 9

2.2 Intended use............................................................... 11

2.3 Safety signs................................................................ 12

2.4 Safety devices............................................................ 14

2.5 Residual risks............................................................. 17

2.5.1 Basic dangers at the workplace............................... 17

2.5.2 Electric shock hazard............................................... 18

2.5.3 Danger due to hydraulics......................................... 18

2.5.4 Hazards associated with the pneumatic system...... 19

2.5.5 Mechanical hazards................................................. 19

2.5.6 Thermal dangers...................................................... 20

2.5.7 Dangers due to hazardous substances and oper-

ating materials......................................................... 20

2.6 Behaviour in the event of an emergency.................... 22

2.7 Personnel requirements.............................................. 22

2.8 Responsibility of the operating company.................... 24

2.9 Personal protective equipment................................... 25

2.10 Spare parts............................................................... 27

2.11 Environmental protection.......................................... 28

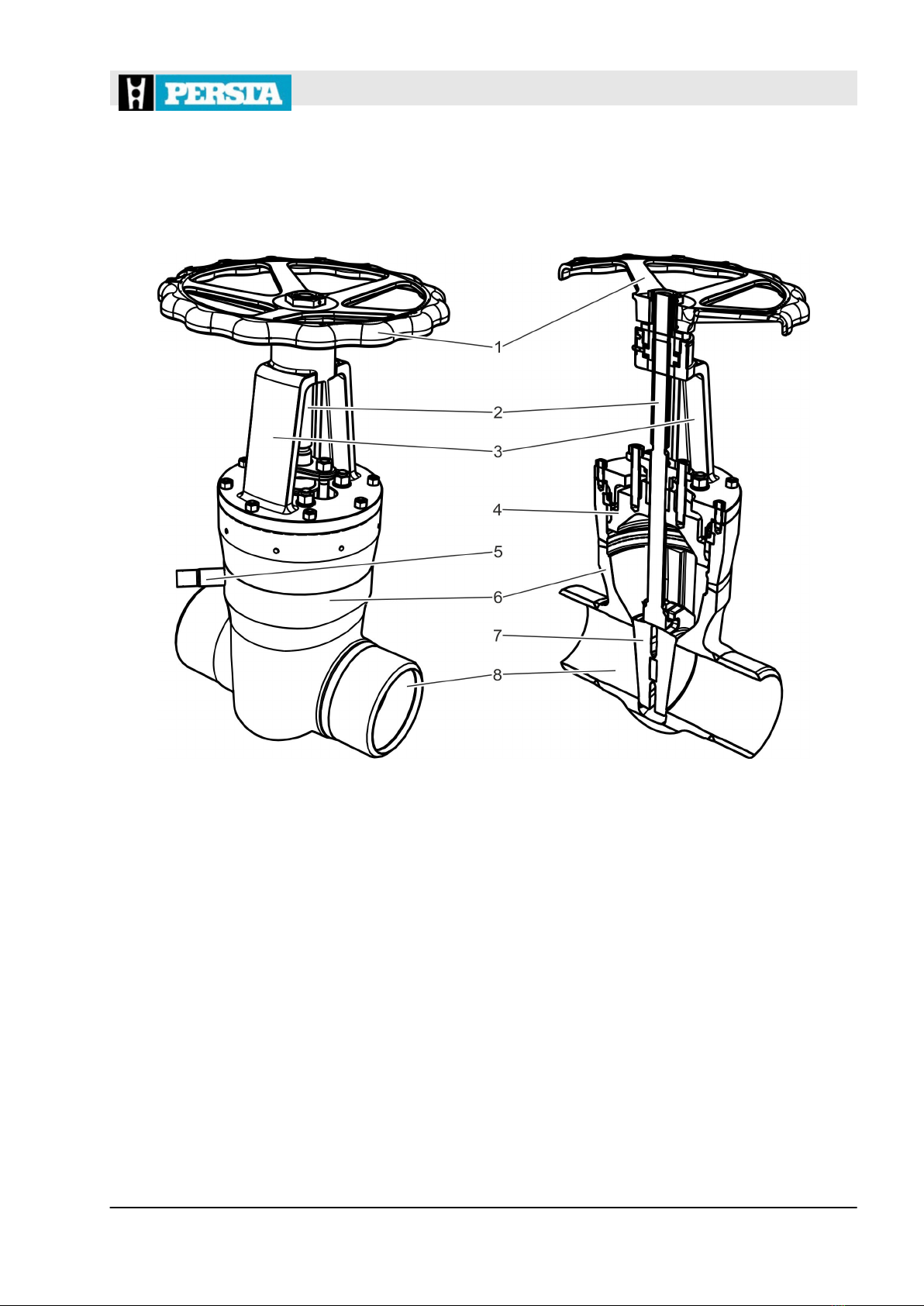

3 Functional description..................................................... 29

3.1 Mode of operation of the high pressure gate valve..... 29

3.2 Seal to the outside...................................................... 30

3.3 Versions of the high pressure gate valve ................... 31

3.3.1 Shut-off element....................................................... 31

3.3.2 Actuator variants...................................................... 33

3.3.3 Display elements..................................................... 36

3.3.4 Connections............................................................. 36

4 Transport and storage...................................................... 39

4.1 Safety instructions for transport and storage.............. 39

4.2 Transport of packages................................................ 40

4.3 Storage of the valve.................................................... 41

4.4 Storage of spare parts................................................ 41

5 Installation......................................................................... 43

5.1 Safety instructions for installation............................... 43

5.2 Before the installation................................................. 45

5.3 Installing the valve...................................................... 46

5.4 Attaching additional safety devices............................. 46

5.5 For electric actuators, connect the power supply....... 47

5.6 For a hydraulic actuator, connecting the hydraulic

system........................................................................ 47

Table of contents

20.05.2021 High Pressure Gate Valves DSK and DSP 5