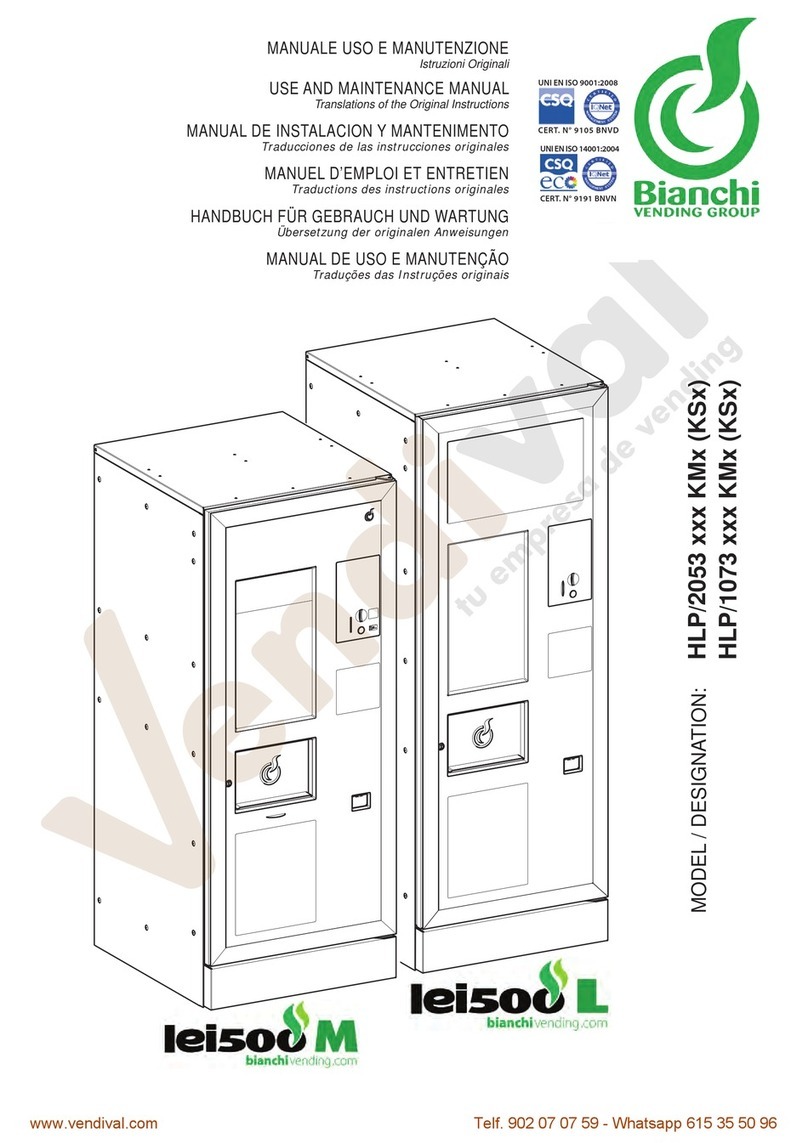

Once the vending machine has been installed in a suitable location in accordance with the instructions in the

manual by authorised Pharmashop24 srl (installer) personnel, and also taking into account the requirements of

the purchaser, three fundamental roles are identified who may interface with the vending machine: the USER,

the MAINTENANCE OPERATIVE and the OPERATOR.

The USER is the end customer who purchases and collects the products displayed on the product shelves, or

shown on the LCD screen, using a selection menu and interacts with devices positioned at a height of

approximately 1.5m from the base of the machine according to the principles of ergonomic design (backlit

keypad, LCD display, touchscreen, card reader, banknote reader, receipt printer and coin acceptor).

Once the desired product has been selected and payment has been made, the purchased item will be deposited

in the product collection compartment, which will be unlocked using an electromagnetic mechanism and can be

opened outwards without the USER coming into contact with the parts inside the display window during

collection. The product collection compartment rotates with its hollow outwards and simultaneously obstructs

any attempt to access the inner part of the vending machine with its inner wall.

The glass display door and the control door can only be opened using special access keys, which are supplied

by Pharmashop24 srl only to experienced personnel, i.e., the OPERATOR and MAINTENANCE OPERATIVE.

The glass display door is made from shatter-proof glass, whereas the outer casing is made of cataphoresis-

treated steel sheets. By virtue of its weight and proper installation by means of suitable fastening devices, the

vending machine is stable enough to prevent it from tipping over and poses no risk to the USER, who has limited

access regarding its operation, even considering any improper use.

The OPERATOR is the person responsible for replacing the products to be sold and collecting the coins and

banknotes that accumulate in the machine, which are inserted by the USER via a banknote reader and coin

acceptor. They are also responsible for replacing the paper used by the printer to issue receipts.

The OPERATOR has greater degree of access than the USER as they are able to operate the vending machine

even with the glass display door and control door open in carrying out their activities. They must have a set of

keys to open the doors, an adequate knowledge in handling the product shelves and their pushers, and

managing the interactive menu (via keypad and display) to deactivate or reactivate vending mode once the

operation is complete.

They must carry out all operations wearing suitable clothing that will not become entangled in the moving or

sharp parts inside the glass display door or the control door, including protective gloves and clothing, and safety

footwear at all times. Work must always be carried out in safety and care must be taken that unauthorised

persons in the vicinity do not impede such activities.

The MAINTENANCE OPERATIVE has an even more extensive level of access than does the OPERATOR. Not only

can they work with the doors open to access the product shelves, but they also include the required training to

work on the mechanisms and drives in the vending machine, as well as change, test, repair and clean the

refrigeration system incorporated in the vending machine, and the electrical system.

The MAINTENANCE OPERATIVE are persons who have the most extensive knowledge of the vending machine

and must work wearing suitable PPE (safety footwear, protective gloves, protective goggles, filter masks, if

required, and protective clothing) and also ensure that all safety parameters are met at all times.

In conclusion, the vending machine must be used for its sole purpose of displaying and vending products, hence

the need for replacement of items, removal of cash and maintenance.