Safety Instructions, Warnings, and Notes

EN 6 LC4.41A AA2.

Device Replacement

The last step in the repair process is to solder the new

component on the board. Ideally, the (LF)BGA should be

aligned under a microscope or magnifying glass. If this is not

possible, try to align the (LF)BGA with any board markers.

So as not to damage neighbouring components, it may be

necessary to reduce some temperatures and times.

More Information

For more information on how to handle BGA devices, visit this

URL: www.atyourservice.ce.philips.com (needs subscription,

not available for all regions). After login, select “Magazine”,

then go to “Repair downloads”. Here you will find Information

on how to deal with BGA-ICs.

2.3.4 Lead-free Solder

Philips CE is producing lead-free sets (PBF) from 1.1.2005

onwards.

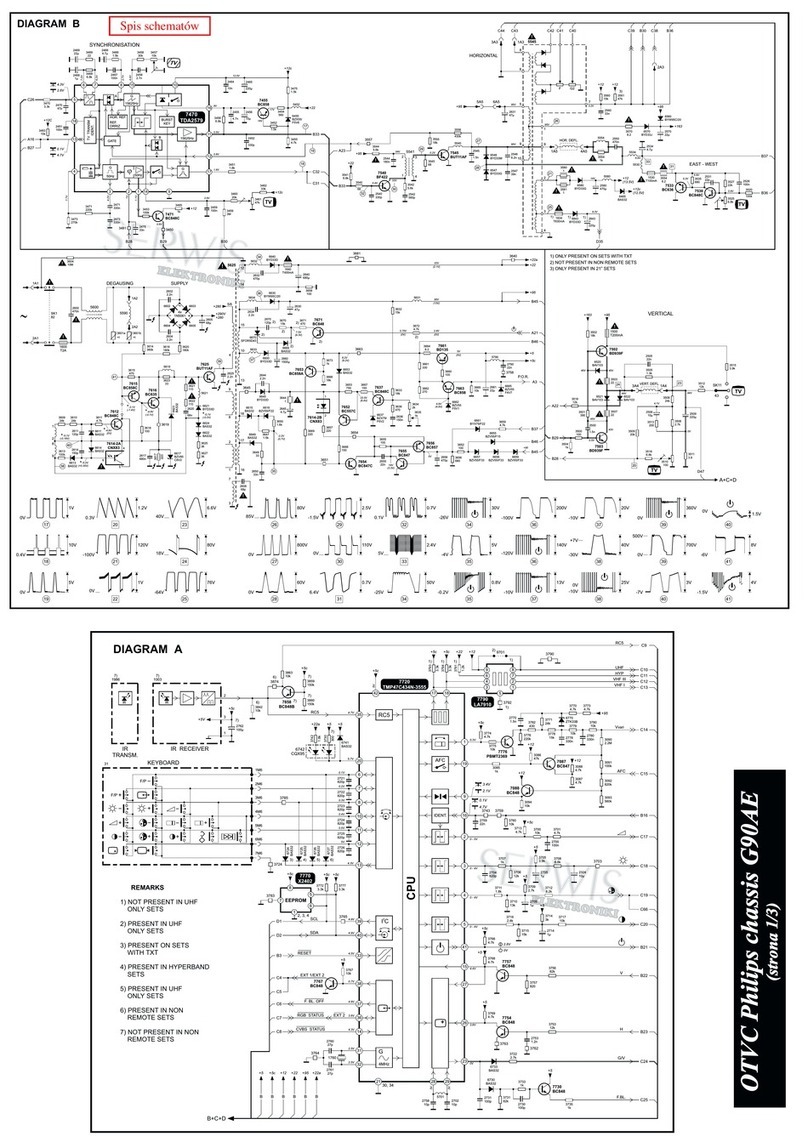

Identification: The bottom line of a type plate gives a 14-digit

serial number. Digits 5 and 6 refer to the production year, digits

7 and 8 refer to production week (in example below it is 1991

week 18).

Figure 2-1 Serial number example

Regardless of the special lead-free logo (which is not always

indicated), one must treat all sets from this date onwards

according to the rules as described below.

Figure 2-2 Lead-free logo

Due to lead-free technology some rules have to be respected

by the workshop during a repair:

• Use only lead-free soldering tin Philips SAC305 with order

code 0622 149 00106. If lead-free solder paste is required,

please contact the manufacturer of your soldering

equipment. In general, use of solder paste within

workshops should be avoided because paste is not easy to

store and to handle.

• Use only adequate solder tools applicable for lead-free

soldering tin. The solder tool must be able:

– To reach a solder-tip temperature of at least 400°C.

– To stabilise the adjusted temperature at the solder-tip.

– To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature of around

360°C - 380°C is reached and stabilised at the solder joint.

Heating time of the solder-joint should not exceed ~ 4 sec.

Avoid temperatures above 400°C, otherwise wear-out of

tips will increase drastically and flux-fluid will be destroyed.

To avoid wear-out of tips, switch “off” unused equipment or

reduce heat.

• Mix of lead-free soldering tin/parts with leaded soldering

tin/parts is possible but PHILIPS recommends strongly to

avoid mixed regimes. If this cannot be avoided, carefully

clear the solder-joint from old tin and re-solder with new tin.

• Use only original spare-parts listed in the Service-Manuals.

Not listed standard material (commodities) has to be

purchased at external companies.

• Special information for lead-free BGA ICs: these ICs will be

delivered in so-called "dry-packaging" to protect the IC

against moisture. This packaging may only be opened

shortly before it is used (soldered). Otherwise the body of

the IC gets "wet" inside and during the heating time the

structure of the IC will be destroyed due to high (steam-)

pressure inside the body. If the packaging was opened

before usage, the IC has to be heated up for some hours

(around 90°C) for drying (think of ESD-protection!).

Do not re-use BGAs at all!

• For sets produced before 1.1.2005, containing leaded

soldering tin and components, all needed spare parts will

be available till the end of the service period. For the repair

of such sets nothing changes.

In case of doubt whether the board is lead-free or not (or with

mixed technologies), you can use the following method:

• Always use the highest temperature to solder, when using

SAC305 (see also instructions below).

• De-solder thoroughly (clean solder joints to avoid mix of

two alloys).

Caution: For BGA-ICs, you must use the correct temperature-

profile, which is coupled to the 12NC. For an overview of these

profiles, visit the website www.atyourservice.ce.philips.com

(needs subscription, but is not available for all regions)

You will find this and more technical information within the

"Magazine", chapter "Repair downloads".

For additional questions please contact your local repair help

desk.

2.3.5 Alternative BOM identification

In September 2003, Philips CE introduced a change in the way

the serial number (or production number, see Figure 2-1) is

composed. From this date on, the third digit in the serial

number (example: AG2B0335000001) indicates the number of

the alternative BOM (Bill of Materials used for producing the

specific model of TV set). It is possible that the same TV model

on the market is produced with e.g. two different types of

displays, coming from two different O.E.M.s.

By looking at the third digit of the serial number, the service

technician can see if there is more than one type of B.O.M.

used in the production of the TV set he is working with. He can

then consult the At Your Service Web site, where he can type

in the Commercial Type Version Number of the TV set (e.g.

28PW9515/12), after which a screen will appear that gives

information about the number of alternative B.O.M.s used.

If the third digit of the serial number contains the number 1

(example: AG1B033500001), then there is only one B.O.M.

version of the TV set on the market. If the third digit is a 2

(example: AG2B0335000001), then there are two different

B.O.M.s. Information about this is important for ordering

the correct spare parts!

For the third digit, the numbers 1...9 and the characters A...Z

can be used, so in total: 9 plus 26 = 35 different B.O.M.s can

be indicated by the third digit of the serial number.

2.3.6 Practical Service Precautions

•It makes sense to avoid exposure to electrical shock.

While some sources are expected to have a possible

dangerous impact, others of quite high potential are of

limited current and are sometimes held in less regard.

•Always respect voltages. While some may not be

dangerous in themselves, they can cause unexpected

reactions that are best avoided. Before reaching into a

powered TV set, it is best to test the high voltage insulation.

It is easy to do, and is a good service precaution.

E_06532_024.eps

130606

MODEL :

PROD.NO:

~

S

32PF9968/10

MADE IN BELGIUM

220-240V 50/60Hz

128W

AG 1A0617 000001

VHF+S+H+UHF

BJ3.0E LA

P

b