Page 3 EVERFLOTM SERVICE & TECHNICAL INFORMATION 1039055, VER. 06

Chapter 1. INTRODUCTION............................................................................................................5

1.1 EVERFLO OXYGEN CONCENTRATOR OVERVIEW ............................................................................. 5

1.2 SERVICE NOTICE.................................................................................................................................... 5

1.3 SERVICE TRAINING................................................................................................................................. 5

1.4 SERVICE/TECHNICAL SUPPORT STATEMENT.................................................................................... 5

Chapter 2. WARNINGS & CAUTIONS...........................................................................................6

2.1 WARNINGS............................................................................................................................................... 6

2.2 CAUTIONS................................................................................................................................................ 7

Chapter 3. SPECIFICATIONS & CLASSIFICATIONS....................................................................8

3.1 SPECIFICATIONS..................................................................................................................................... 8

Chapter 4. THEORY OF OPERATION..........................................................................................10

4.1 PNEUMATIC OPERATION.....................................................................................................................10

4.2 ELECTRICAL OPERATION.................................................................................................................... 12

4.3 PCA CONTROLLER OVERVIEW...........................................................................................................12

Chapter 5. SYSTEM SETUP.........................................................................................................14

5.1 INTRODUCTION..................................................................................................................................... 14

5.2 SYSTEM SETUP PROCEDURES.......................................................................................................... 14

Chapter 6. MAINTENANCE...........................................................................................................16

6.1 DEALER ROUTINE MAINTENANCE.....................................................................................................16

6.2 EVERFLO OXYGEN CONCENTRATOR MAINTENANCE RECORD....................................................17

6.3 SYSTEM VERIFICATION PROCEDURES ............................................................................................ 18

Chapter 7. TROUBLESHOOTING & ALARMS.............................................................................31

7.1 INTRODUCTION..................................................................................................................................... 31

7.2 INDICATORS & ALARMS.......................................................................................................................31

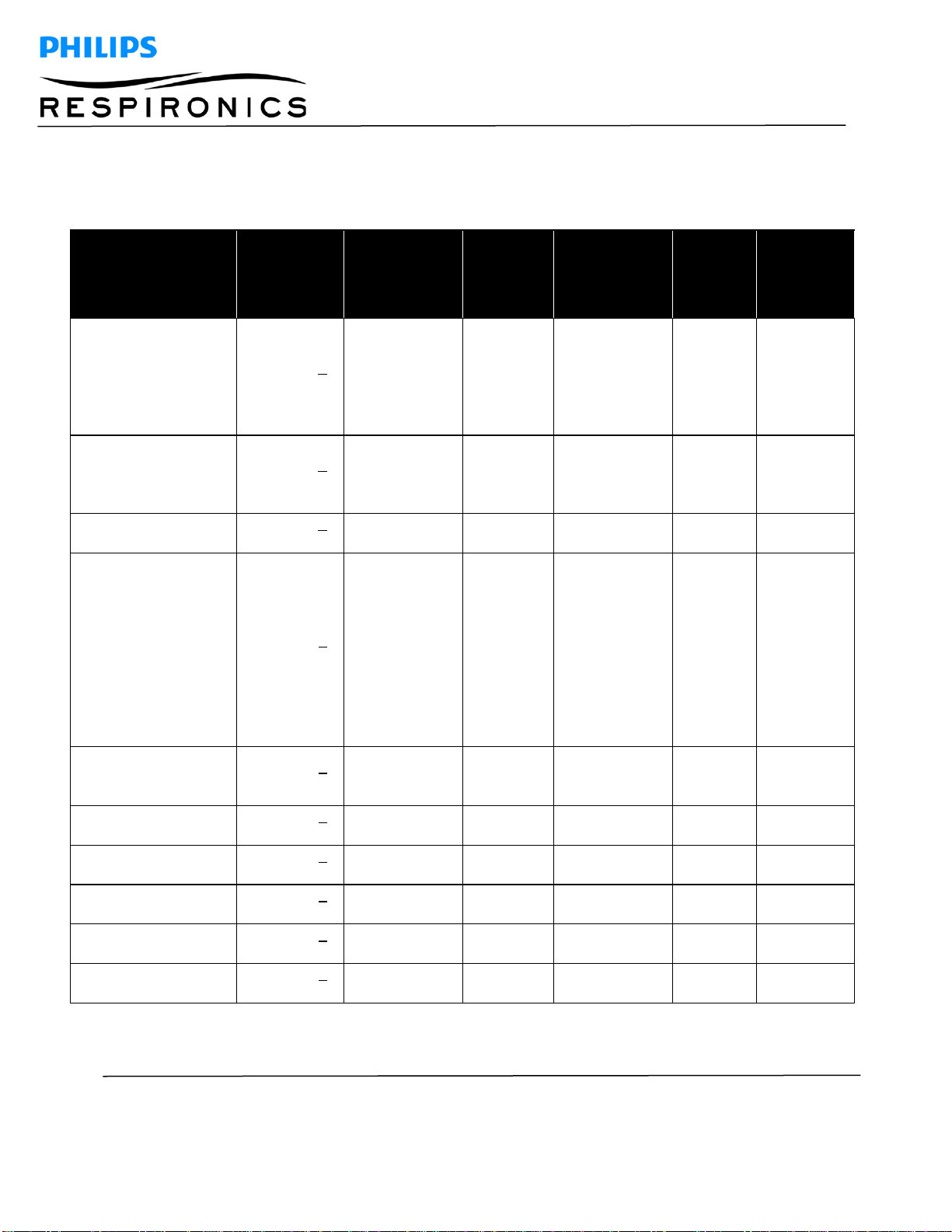

7.3 TROUBLESHOOTING TABLE................................................................................................................32

7.4 SYSTEM PRESSURE TEST TABLE ......................................................................................................39

Chapter 8. REPAIR & REPLACEMENT.......................................................................................40

8.1 OVERVIEW .............................................................................................................................................40

8.2 REPAIR KIT REFERENCE TABLE.........................................................................................................41

8.3 FILTER COVER REPLACEMENT..........................................................................................................44

8.4 INLET FILTER REPLACEMENT ............................................................................................................ 45

8.5 REAR CABINET/POWER CORD REPLACEMENT............................................................................... 46

8.6 O2 QUICK COUPLER REPLACEMENT................................................................................................49