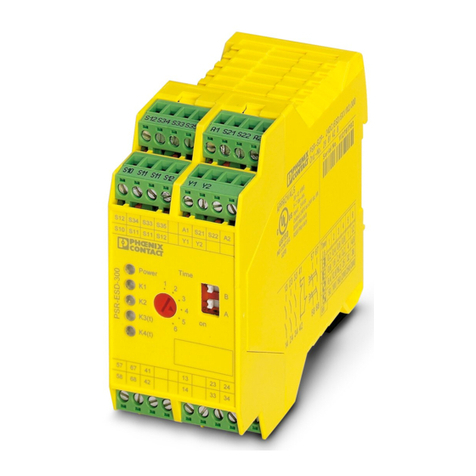

PSRmodular system

4 / 232 PHOENIX CONTACT 109241_en_03

4.2.5 Function windows: Items – Operator – Configuration ........................... 43

4.2.6 Creating the safety logic ....................................................................... 44

4.2.7 Calling functions in the context menu ................................................... 45

4.2.8 Project example ................................................................................... 46

4.2.9 Saving the project ................................................................................ 46

4.2.10 Validating the project ........................................................................... 46

4.2.11 Resource allocation ............................................................................. 47

4.2.12 Project report ....................................................................................... 48

4.2.13 Connecting to the base module ........................................................... 50

4.2.14 Password protection ............................................................................ 51

4.2.15 Establishing a USB connection ............................................................ 52

4.2.16 Monitor (status of I/Os) ......................................................................... 55

4.2.17 Monitor graphic .................................................................................... 56

4.2.18 System test .......................................................................................... 57

5 Items and operators of the PSRmodular Software ...................................................................59

5.1 Item function blocks............................................................................................. 59

5.1.1 Output item .......................................................................................... 59

5.1.2 INPUT item .......................................................................................... 71

5.2 Speed control .................................................................................................... 100

5.2.1 General information on the “Error Out” parameter .............................. 100

5.2.2 Function blocks .................................................................................. 101

5.3 Analog function block ........................................................................................ 121

5.3.1 ANALOG INPUT function block ......................................................... 121

5.4 Operator function blocks.................................................................................... 133

5.4.1 Logical operators ............................................................................... 133

5.4.2 MEMORY operators .......................................................................... 143

5.4.3 GUARD-LOCKING operator .............................................................. 151

5.4.4 COUNTER operators ......................................................................... 163

5.4.5 TIMER operators ................................................................................ 166

5.4.6 MUTING operators ............................................................................ 177

5.5 Analog operators ............................................................................................... 189

5.5.1 ANALOG COMPARATOR ................................................................. 189

5.5.2 ADDER .............................................................................................. 189

5.5.3 Equality Check ................................................................................... 190

5.6 Miscellaneous ................................................................................................... 192

5.6.1 Other operators .................................................................................. 192

5.6.2 Simulator features .............................................................................. 203

6 Installation and startup ...........................................................................................................211

6.1 Example for installation and startup................................................................... 211