2

1 Warning

⚠

Improper Use, Installation or Maintenance may result in serious injury or death.

⚠

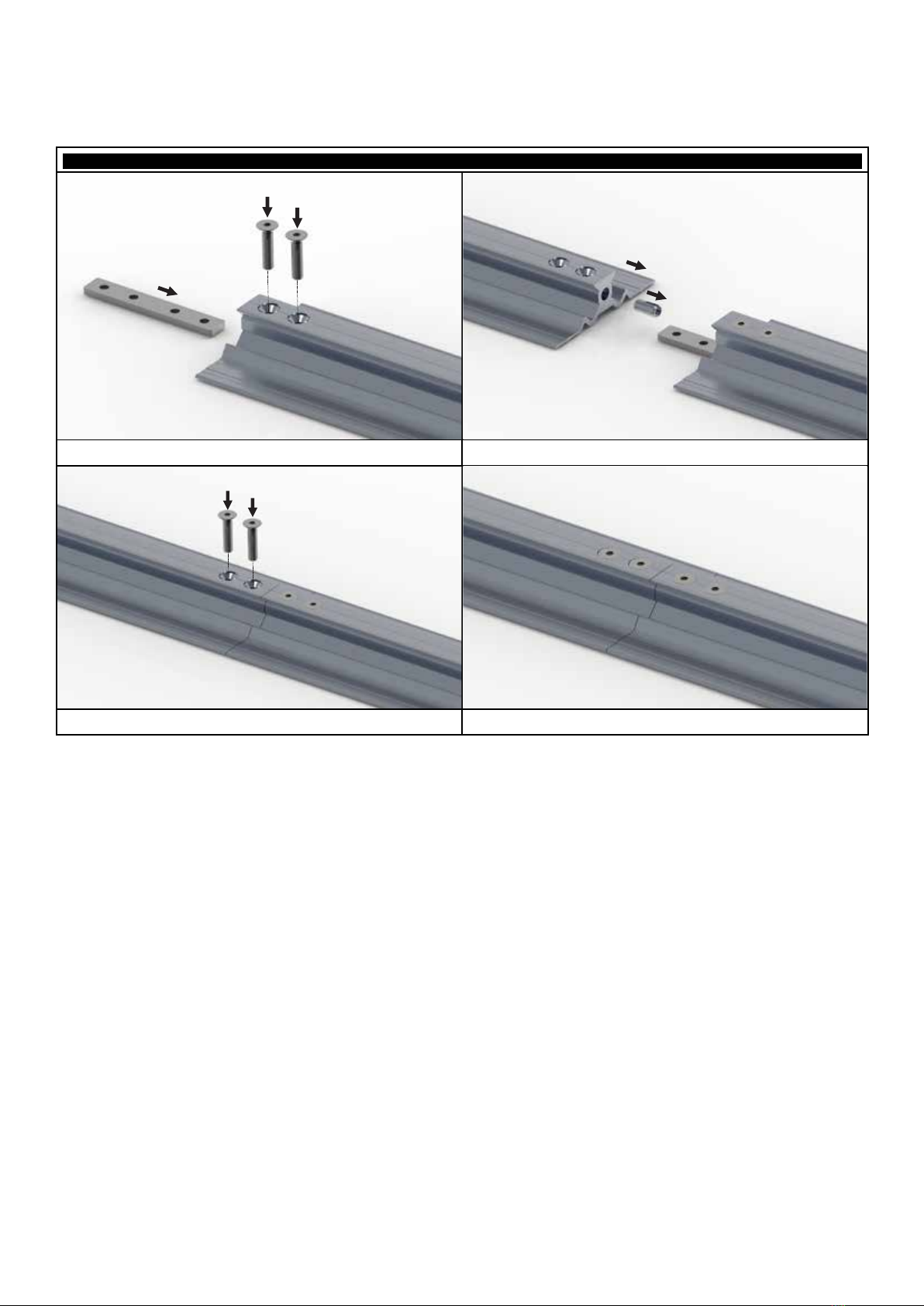

The building or structure for the anchorages should be assessed by an engineer to

ensure that the structure is adequate for X-Rail installation works.

⚠

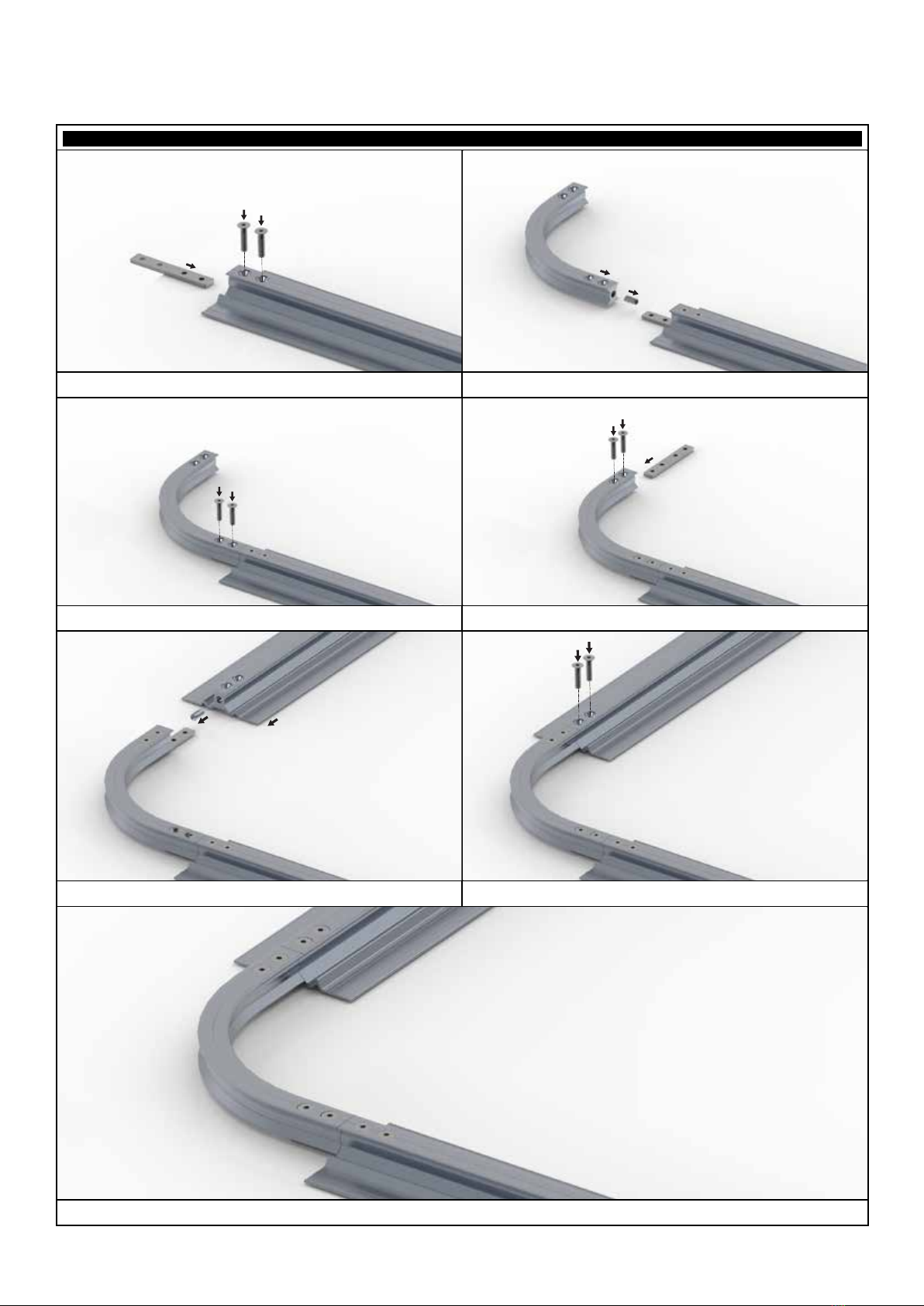

SafetyLink's Height Safety Systems must only be installed as per our installation

guides, to structures as specified in the installation manual for each product.

⚠

All safety procedures must be complied with in accordance with the current safety

code(s) of practice(s) for working at heights in your region. Ensure safety at all times by

being attached to suitable anchor points and approved safety equipment or approved

scaffolding.

⚠

Installation is to be carried out by, or under the supervision of, a competent person.

⚠

A personal energy absorber or a fall-arrest device with a personal energy absorber

must be used in conjunction with all SafetyLink Anchorages and Lifeline systems.

⚠

Do not carry out any modifications on this system without written permission by

SafetyLink Pty Ltd.

2 Specification

2.1 Description

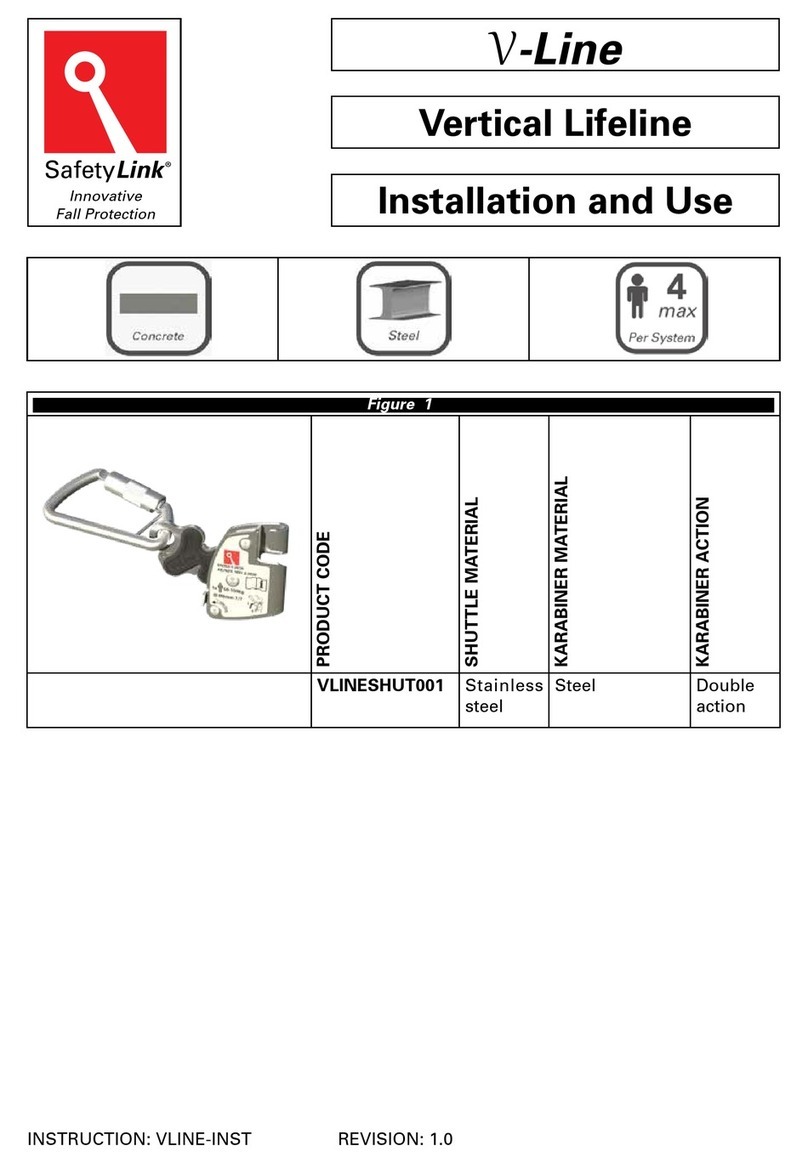

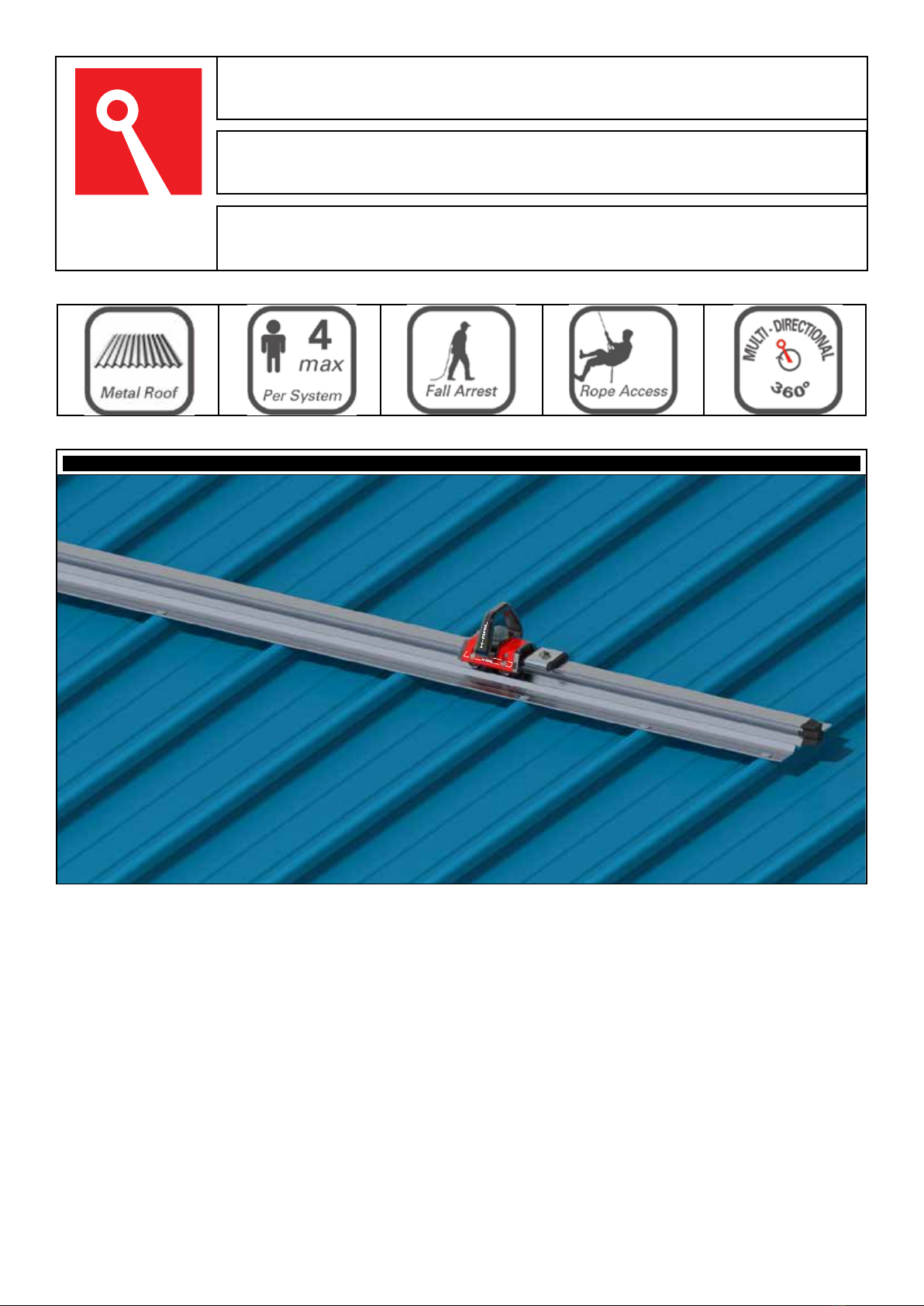

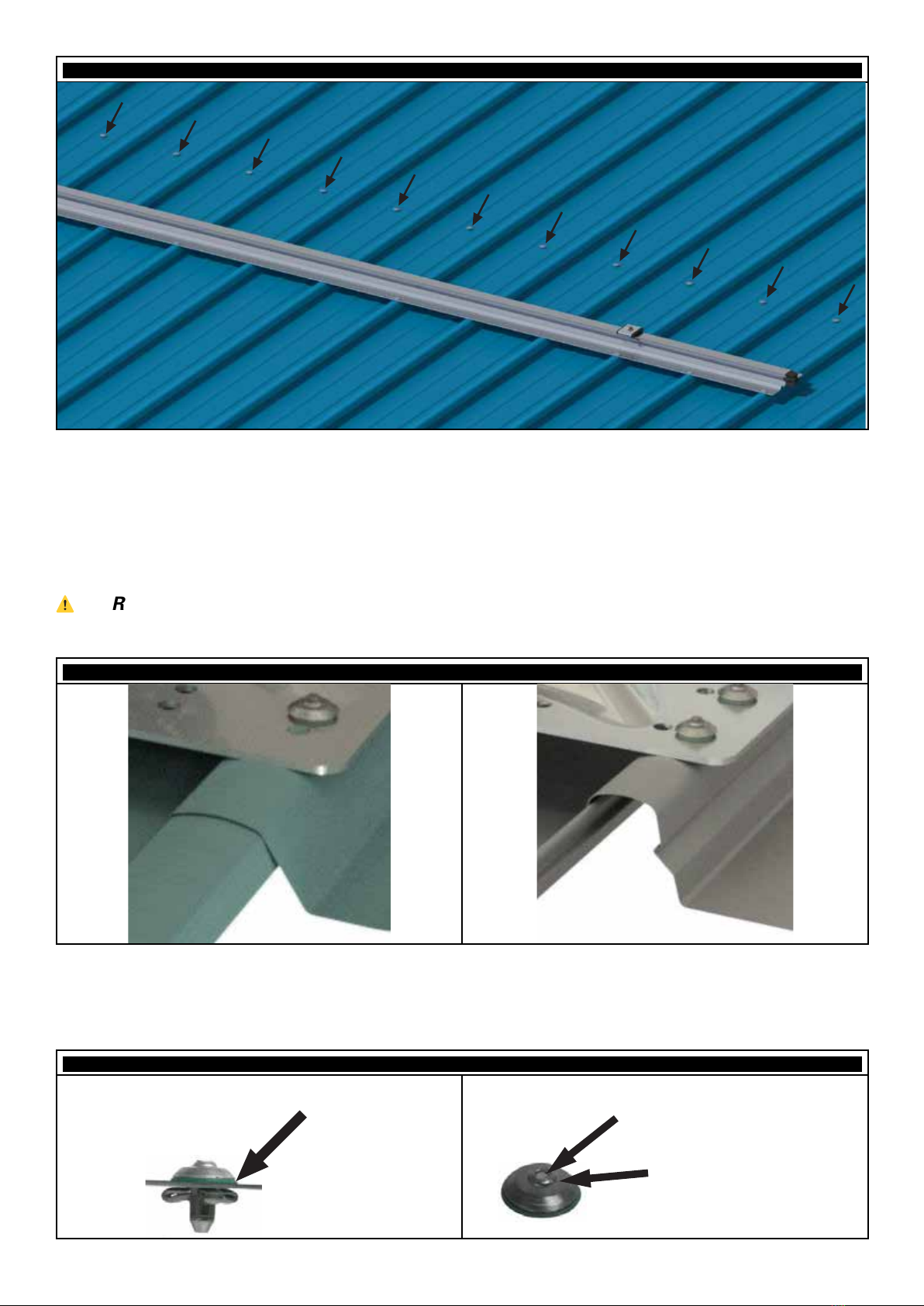

The SafetyLink X-Rail is a Rigid Anchor Line suitable for use as part of a personal fall protection

system. The X-Rail offers a horizontal Rigid Anchor Line with one or multiple Mobile Anchor

Points for attaching to.

2.2 Standard

The X-Rail Rigid Anchor Line System is compliant with AS/NZS 1891.2, EN795:2012 and PD

CEN/TS 16415:2013.

2.3 User Rating

The X-Rail Rigid Anchor Line is rated for up to 4 users per system and in any span.

2.4 Material Specification

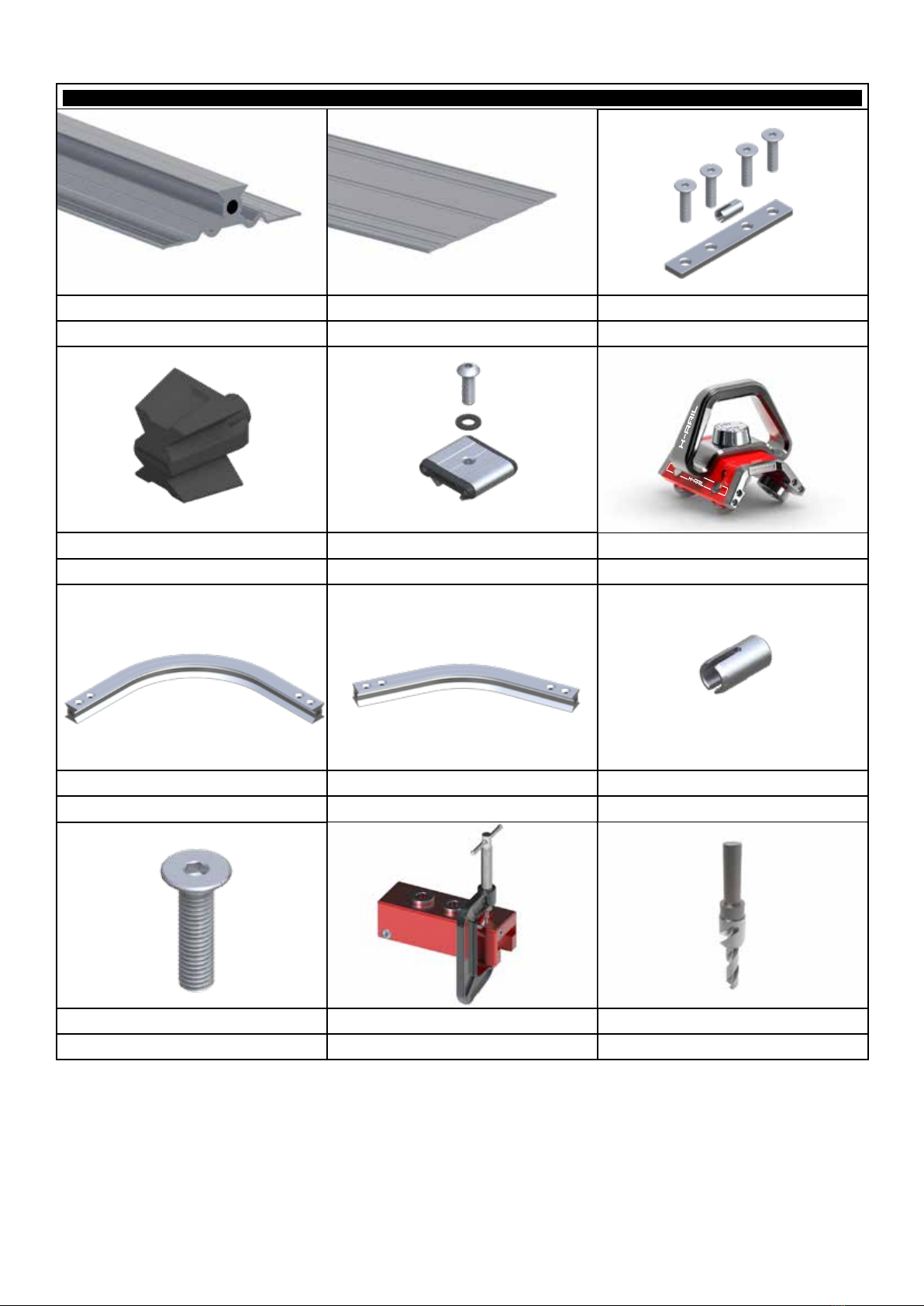

COMPONENT DESCRIPTION

Rail Aluminium 6000 series

Cross Plates Aluminium 6000 series

Joins Aluminium 6000 series

Fasteners Stainless steel 316

End Cap Nylon 66

End Stop Aluminium 6000 series, Rubberised Nylon

Shuttle Aluminium 6000 series, Stainless steel 316, Nylon 66