OPS-4427 Rev A i

Table of Contents

Revision History ...........................................................................................ii

Safety.............................................................................................................. iii

1Introduction...............................................................................................1

1.1 General..............................................................................................1

1.2 Product Identification.........................................................................1

2Technical Specification.............................................................................2

3Technical ..................................................................................................4

3.1 Description.........................................................................................4

3.2 Key Product Features........................................................................6

4Operation..................................................................................................8

4.1 Lifting and Handling...........................................................................8

4.2 Setting Up..........................................................................................8

4.3 Pre Job............................................................................................10

4.4 During Job.......................................................................................10

4.5 Post Job...........................................................................................11

5Maintenance...........................................................................................12

5.1 Introduction......................................................................................12

5.2 Schedule..........................................................................................12

5.3 Safety ..............................................................................................13

5.4 Redress Procedure..........................................................................13

5.5 Maintenance Record Sheet .............................................................18

6Testing....................................................................................................19

7Parts List and Drawings..........................................................................20

8Spares ....................................................................................................25

Table 1: Technical Data...................................................................................2

Table 2: Recommended Grease Head Arrangement (Guidance only).............5

Table 3: Maintenance Record........................................................................18

Table 4: Parts List 145-4427-HV0..................................................................21

Table 5 : Redress Kit Part No RDK-4427-HV0 ..............................................25

Figure 1: Grease Head Safety ........................................................................ iii

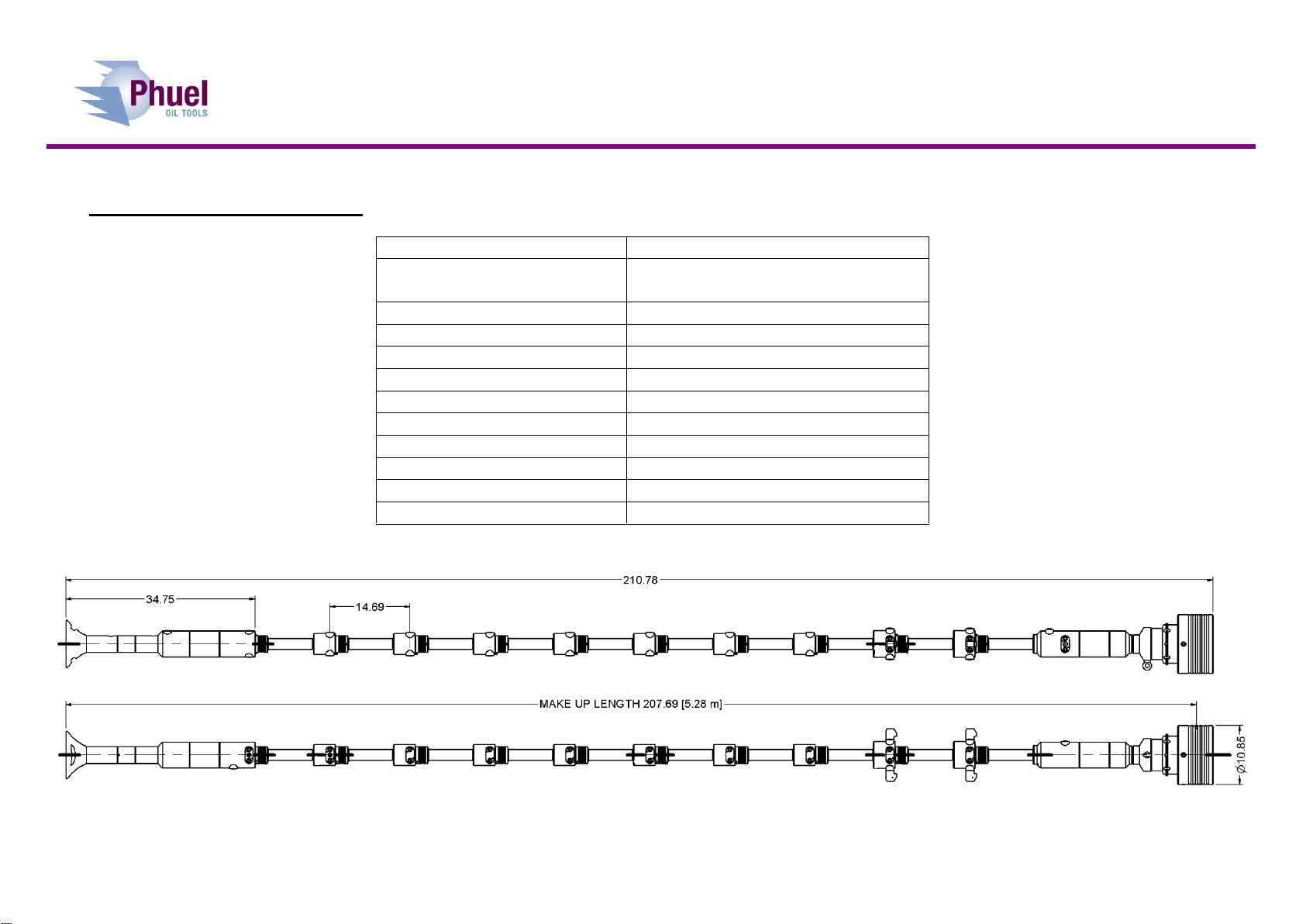

Figure 2: Grease Head ....................................................................................2

Figure 3: Grease Head Connections................................................................3

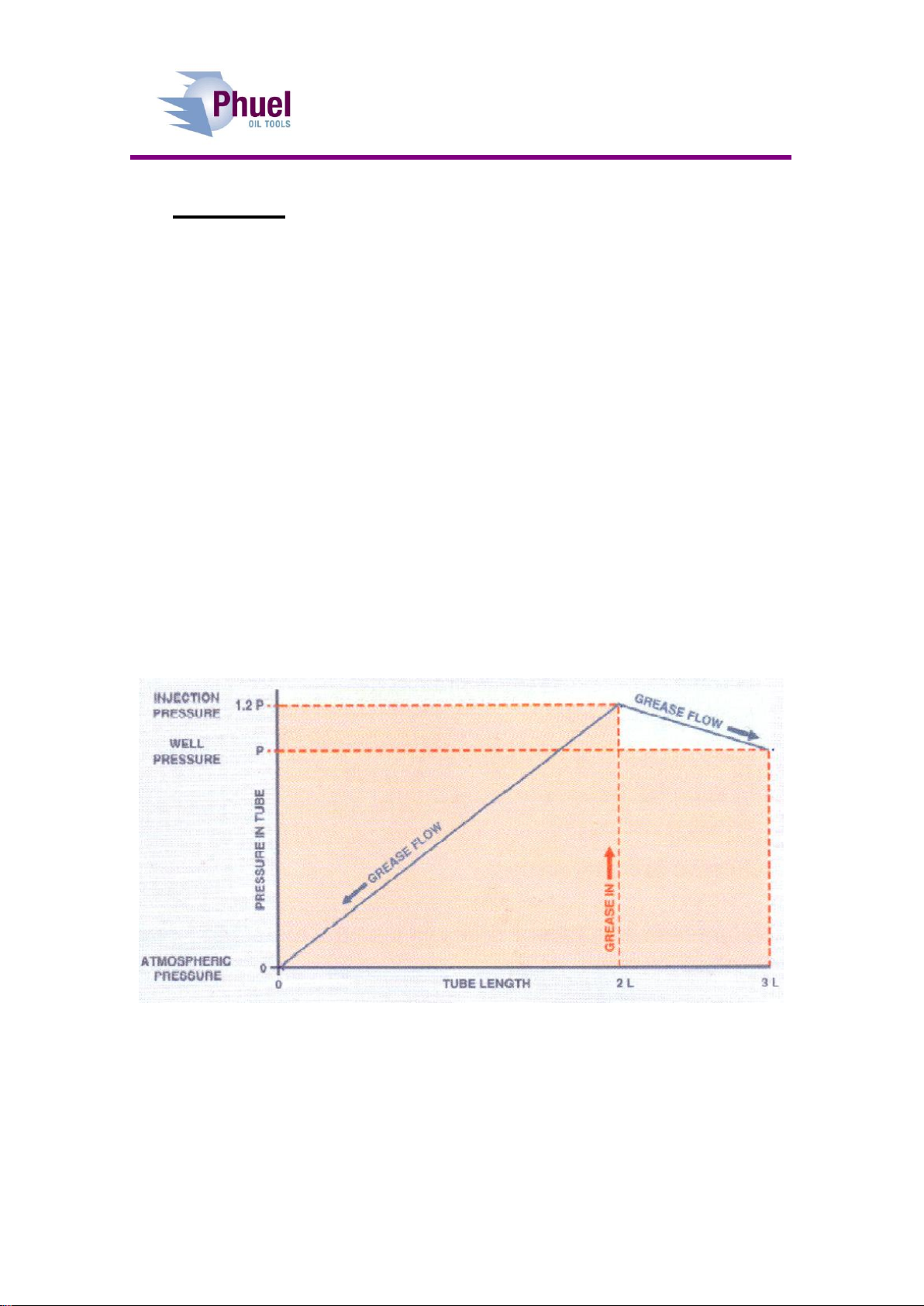

Figure 4: Pressure gradient inside the flow tube assembly..............................4

Figure 5: Couettes flow equation .....................................................................5

Figure 6: Fast Collar ........................................................................................6

Figure 7: Fitting the packing.............................................................................9

Figure 8: Assembly guide –part 1 .................................................................15

Figure 9: Assembly guide –part 2 .................................................................16

Figure 10: Assembly guide –part 3 ...............................................................17

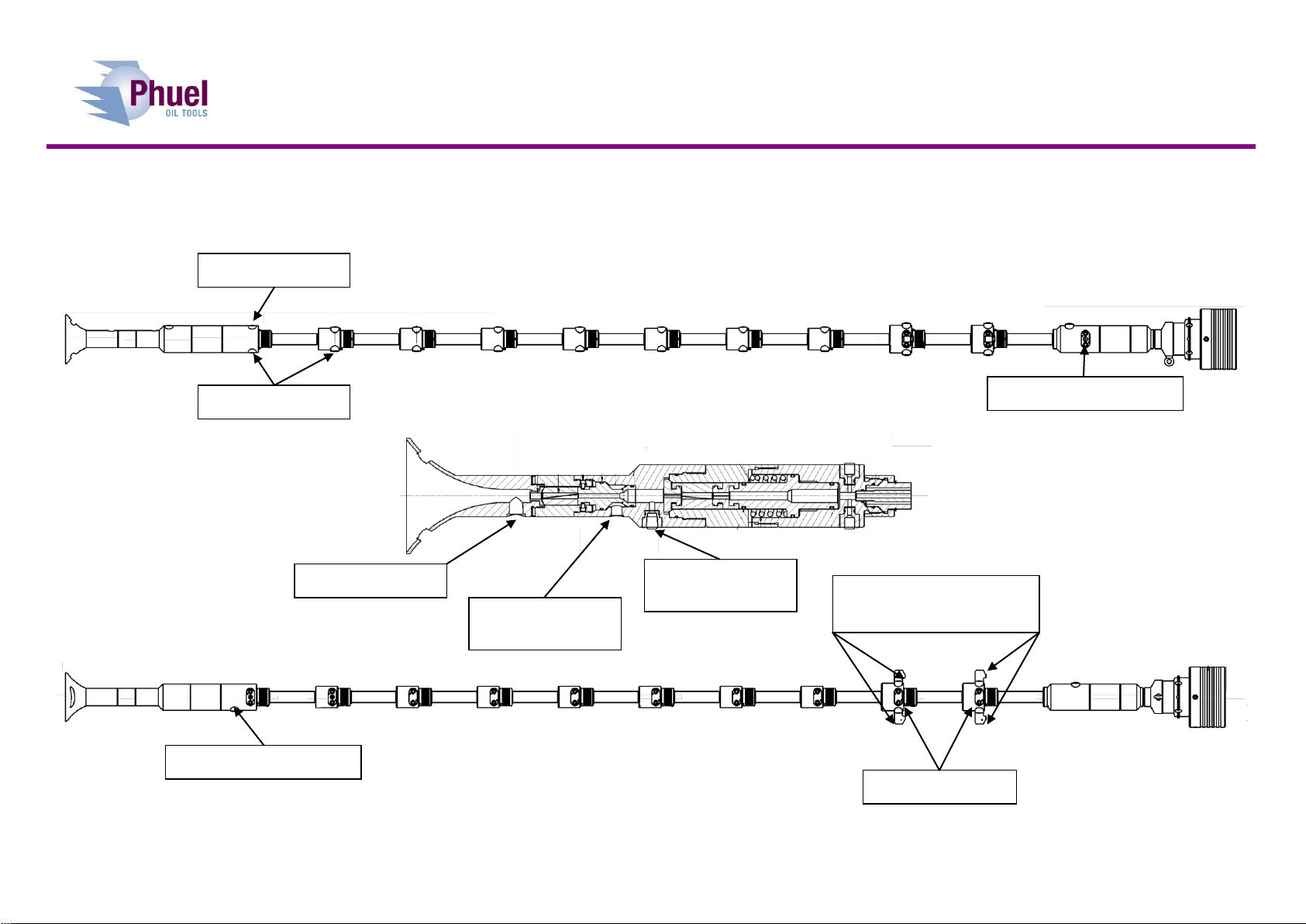

Figure 11: Grease Head Assembly................................................................22

Figure 12: Grease Head Assembly Detail......................................................24