Technical Documentation

Stuffing Box

IPC-4336 Rev C 1

Table of Contents

Revision History ...............................................................................................................................2

1Declaration of Conformity .........................................................................................................3

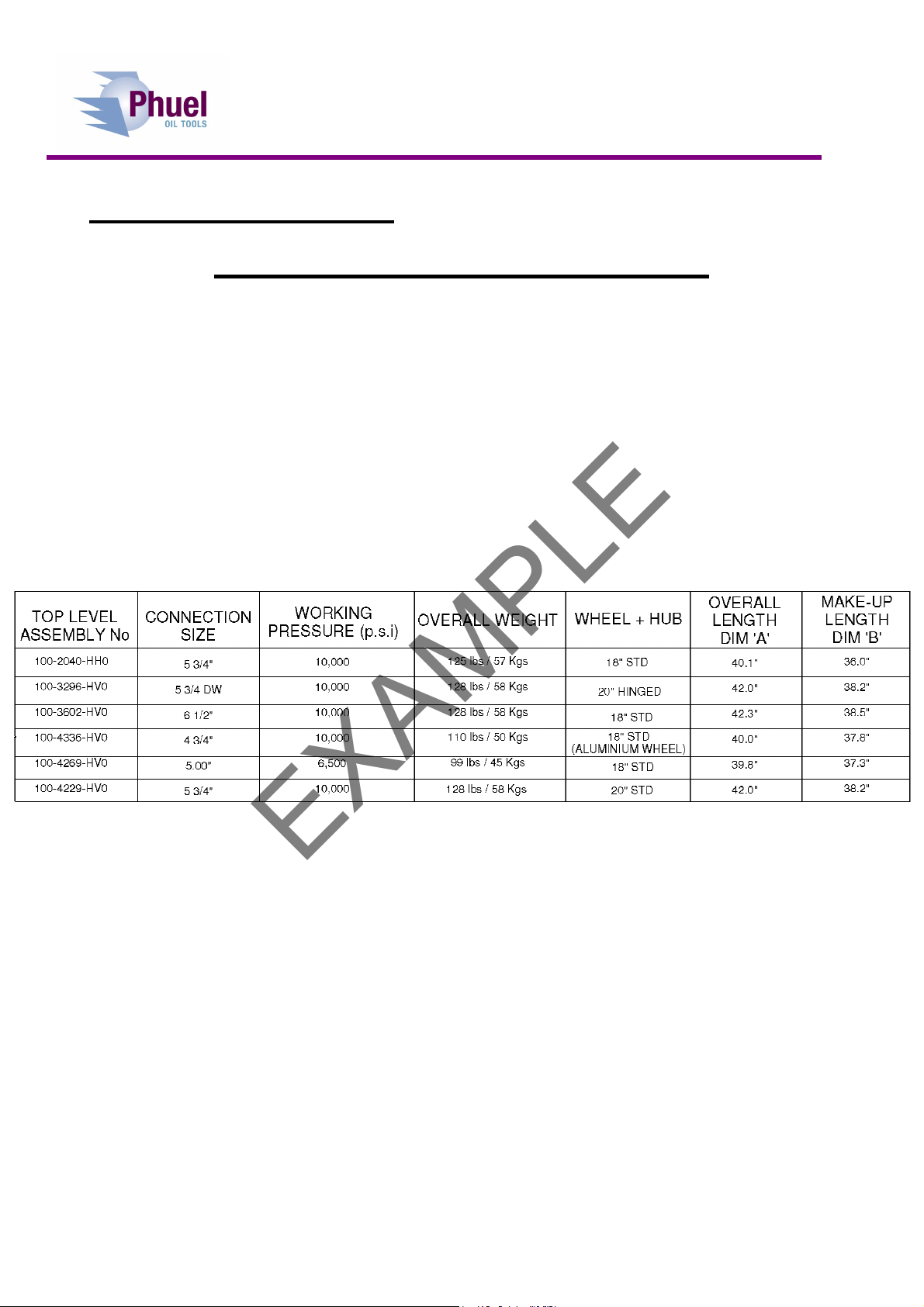

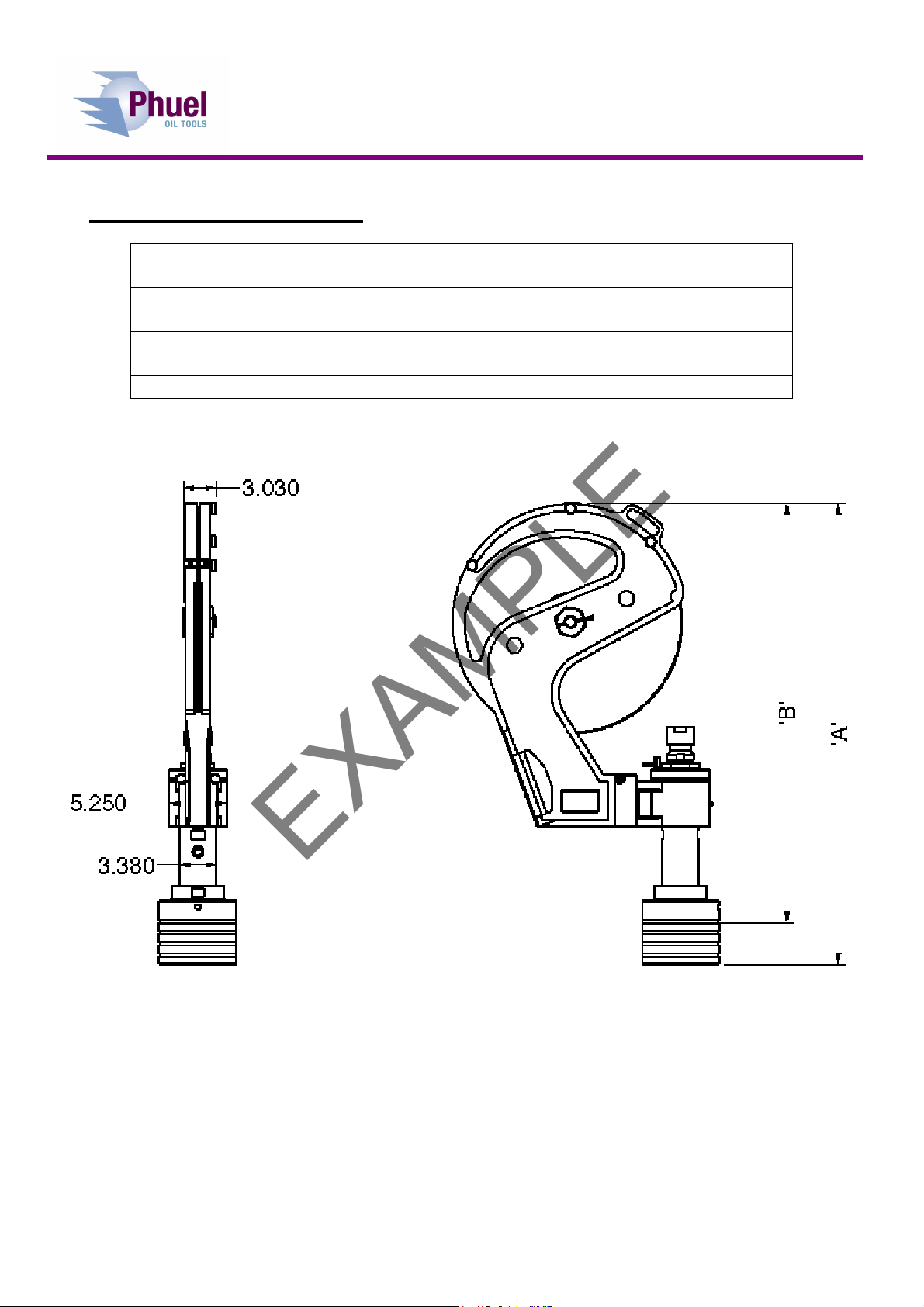

2Technical Specification .............................................................................................................5

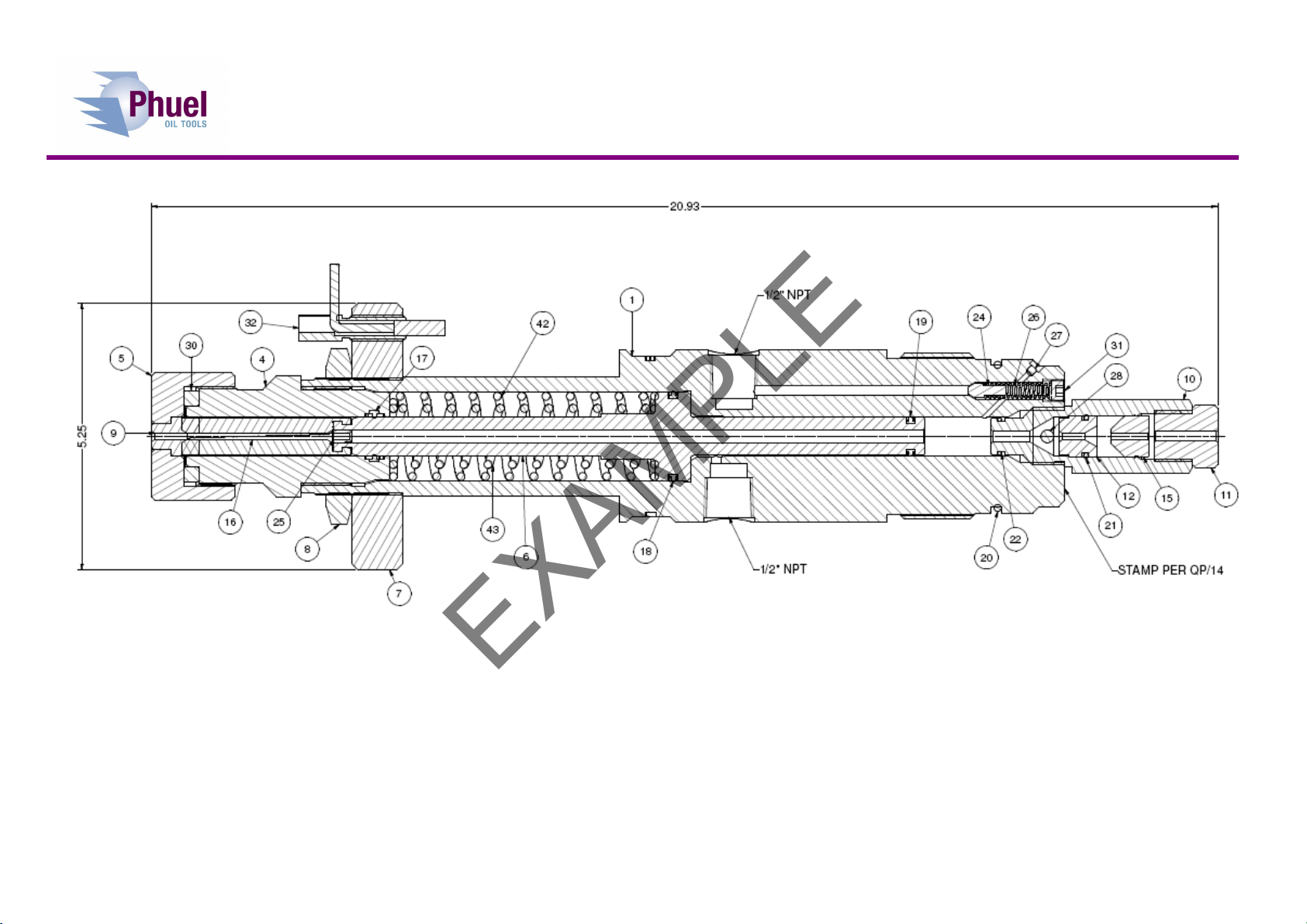

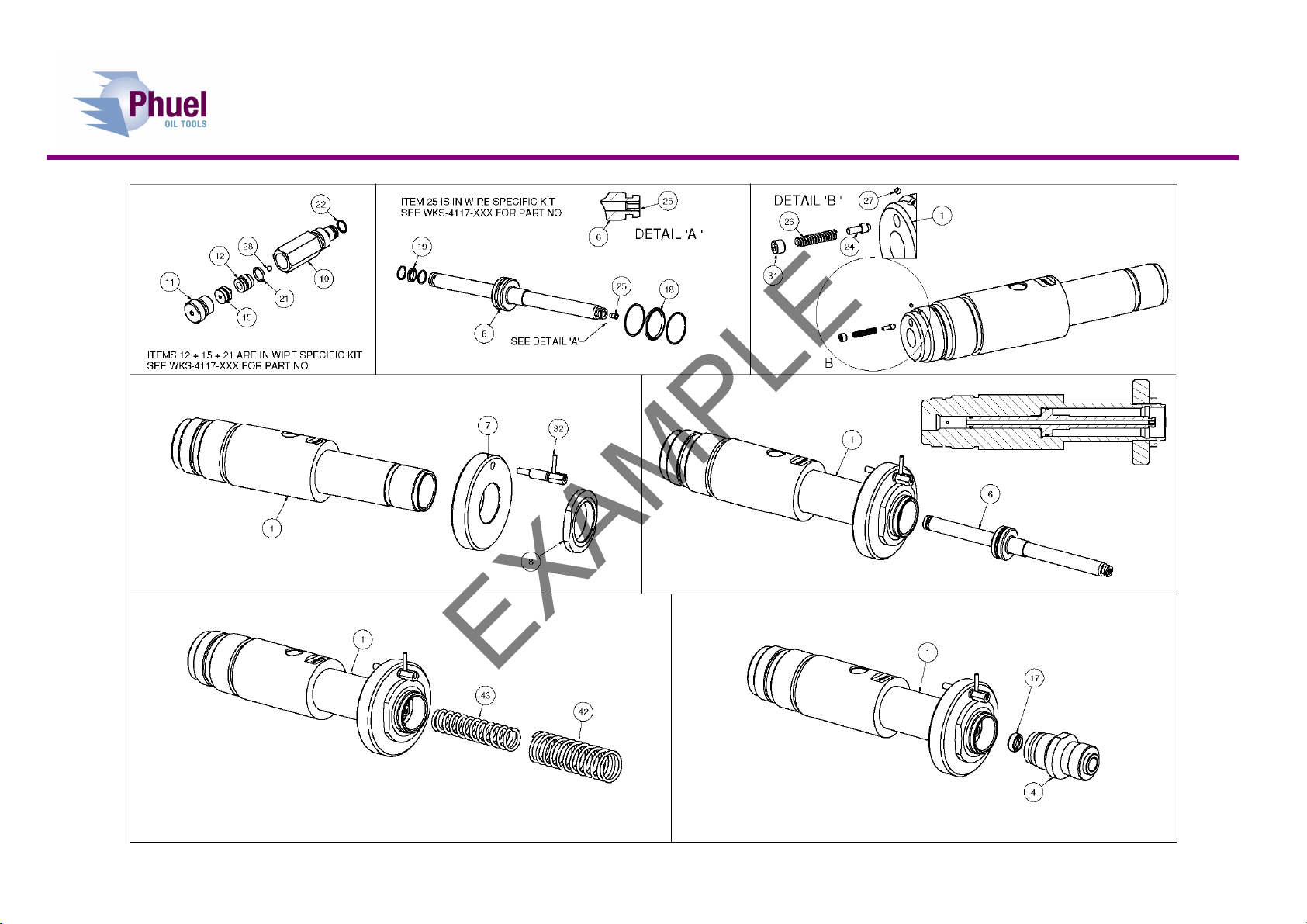

3Parts List and Assembly Drawings ...........................................................................................6

4Spares ....................................................................................................................................12

4.1 Redress Kit ............................................................................................................. 12

4.2 Wire Specific Parts.................................................................................................. 12

4.3 Operation Specific Parts ......................................................................................... 13

4.4 Support Equipment ................................................................................................. 13

Table 1: Technical Data ...................................................................................................................5

Table 2: Parts list 100-4336-HV0.....................................................................................................6

Table 3: 100-4252-HV0 Parts List....................................................................................................6

Table 4: 100-4253-HV4 Parts List..................................................................................................10

Table 5: 100-4250-HV0 Parts List..................................................................................................11

Table 6: Redress Kit Part No RDK-4336-HV0................................................................................12

Table 7: Redress Kit Part No RDK-4252-HV0................................................................................12

Table 8: Wire Kit WKS-4117-092 ...................................................................................................12

Table 9: Wire Kit WKS-4117-108 ...................................................................................................12

Table 10: Wire Kit WKS-4117-125.................................................................................................13

Table 11: Wire Kit WKS-4117-160.................................................................................................13

Table 12: Spacer Selection............................................................................................................13

Table 13: Support Equipment ........................................................................................................13

Figure 1: Dimensional Data..............................................................................................................5

Figure 2: 100-4252-HV0 ..................................................................................................................7

Figure 3: Assembly Procedure.........................................................................................................9

Figure 4: 100-4253-HV4 ................................................................................................................10

Figure 5: 100-4250-HV0 ................................................................................................................11