3

MT 237 –EN ed.2015 (Rev.A)

GENERAL WARNINGS

The equipment described in this manual is a device subject to pressure installed in systems under pressure.

The involved equipment is usually integrated in systems conveying flammable gases (e.g. natural gas).

WARNINGS FOR THE OPERATORS

Before performing the installation, commissioning or maintenance, the operators must:

go through the safety provisions applicable to the installation where they have to operate;

obtain the necessary authorizations to operate, when required;

be equipped with the necessary personal protective equipment (helmet, goggles, etc.)

make sure that the area in which they have to operate is equipped with the required collective protections as well as with the

necessary safety signs.

PACKAGING / TRANSPORT / STORAGE

The packaging materials used for transporting the equipment and the related spare parts have been designed and manufactured to avoid

damages during normal transport, storage, and related handling. Therefore, the equipment and spare parts must be kept in their respective

original packages till their installation in the final destination site. When the packages are opened, it is necessary to verify the integrity of the

materials therein contained. In case of damages, report the detected damages to the suppliers preserving the original package to allow the

performance of necessary inspections.

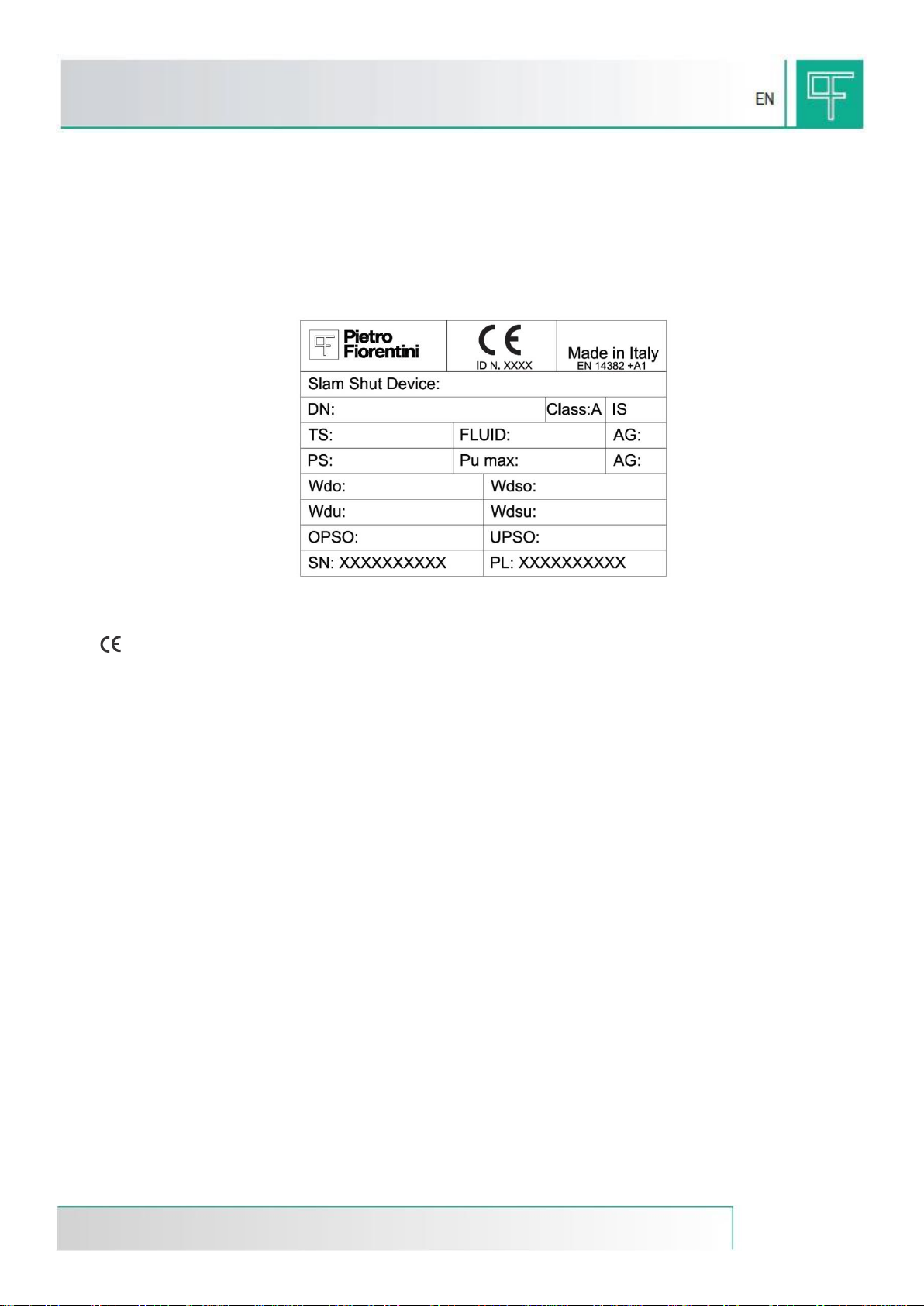

The storage of the equipment, even after their use, must occur in suitable places, free of moisture and away from sources of light and heat,

within the limits stated on the rating plate

HANDLING

The handling of the equipment and its components must be performed after having established that the lifting means are suitable for the

loads to be lifted (lifting capacity and functionality) in order to avoid bumps, impacts and local stresses.

When necessary, the handling of the equipment must be performed using the lifting points foreseen on the equipment itself. The use of

motorized means is reserved to authorized personnel only.

INSTALLATION

The installation of the pressure equipment must occur in compliance with the provisions (laws or regulations) in force in the place of

installation.

In detail, natural gas plants must show features complying with the law provisions or regulations in force in the place of installation or at

least complying with the standards EN 12186 or EN 12279. The installation in compliance with such standards minimizes the risk of fire and

the formation of potentially hazardous atmospheres.

The equipment is not provided with internal pressure limitation devices; therefore, it must be installed making sure that the operating

pressure of the assembly in which it is installed does not exceed the value of the allowable maximum pressure (PS).

The user shall, therefore, when he/she deems it necessary, provide for the installation of suitable pressure limitation systems on the

assembly; Moreover, the user shall equip the plant with suitable relief or drain systems in order to be able to discharge the pressure and the

fluid contained in the plant before proceeding with any inspection and maintenance activity.

Should the installation of the equipment require the installation of compression fittings on site, these latter have to be installed following the

instructions provided by the manufacturer of the fittings. The selection of the fittings must be compatible with the use specified for the

equipment and with the plant specifications, when foreseen.

COMMISSIONING

The commissioning must be carried out by suitably trained personnel.

During the commissioning, the personnel not strictly necessary must be kept away and the limited access area must be properly marked

(signs, barriers, etc.).

Verify that the equipment calibrations are the ones required. If necessary, restore the required values for the same as provided for later on

in this manual.

During the commissioning, the risks determined by any discharges to the atmosphere of flammable or noxious gases must be assessed.

In case of installation on natural gas distribution networks, it is necessary to consider the risk of formation of a (gas/air) explosive mix within

the piping.

COMPLIANCE WITH DIRECTIVE 97/23/EC (PED)

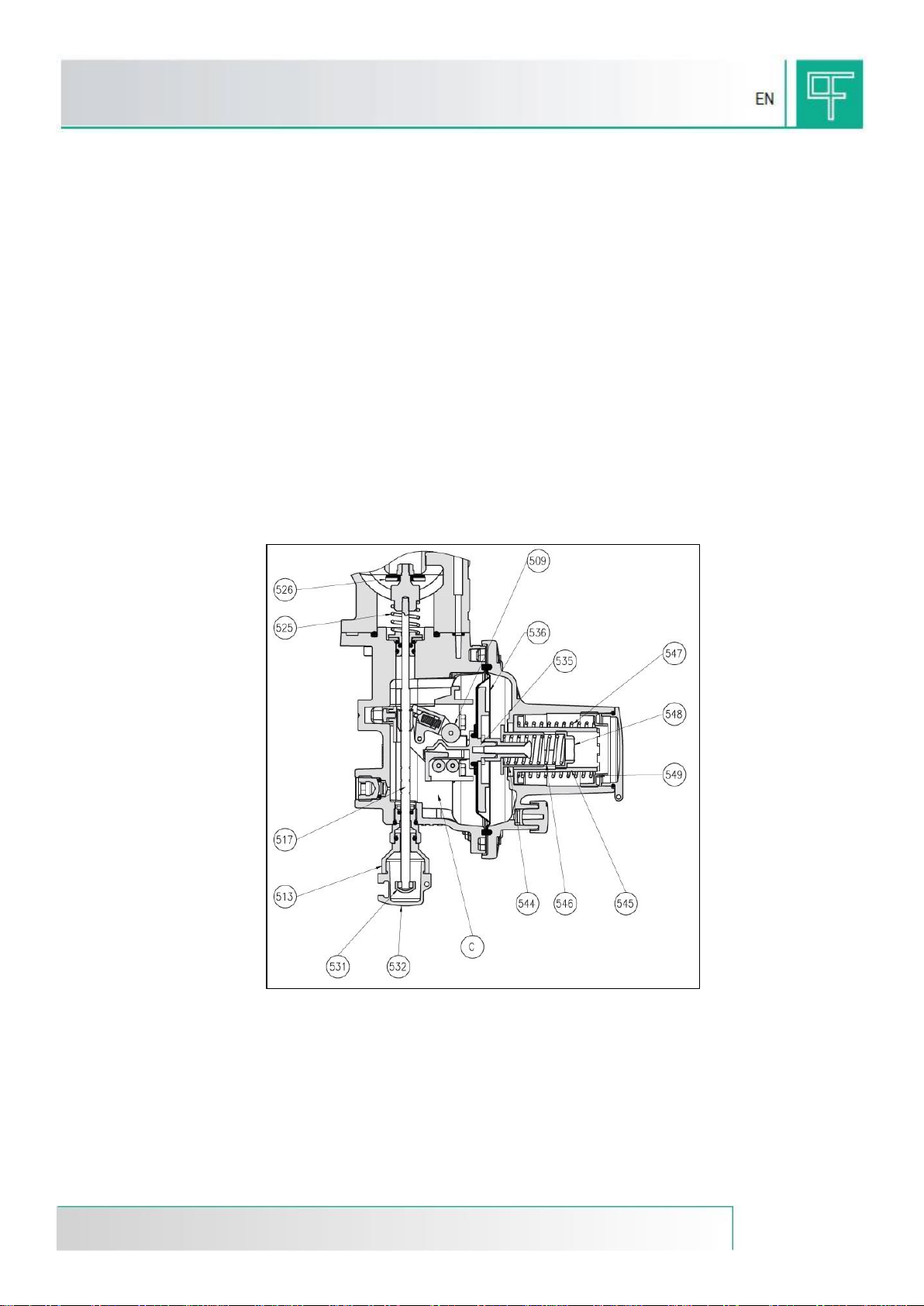

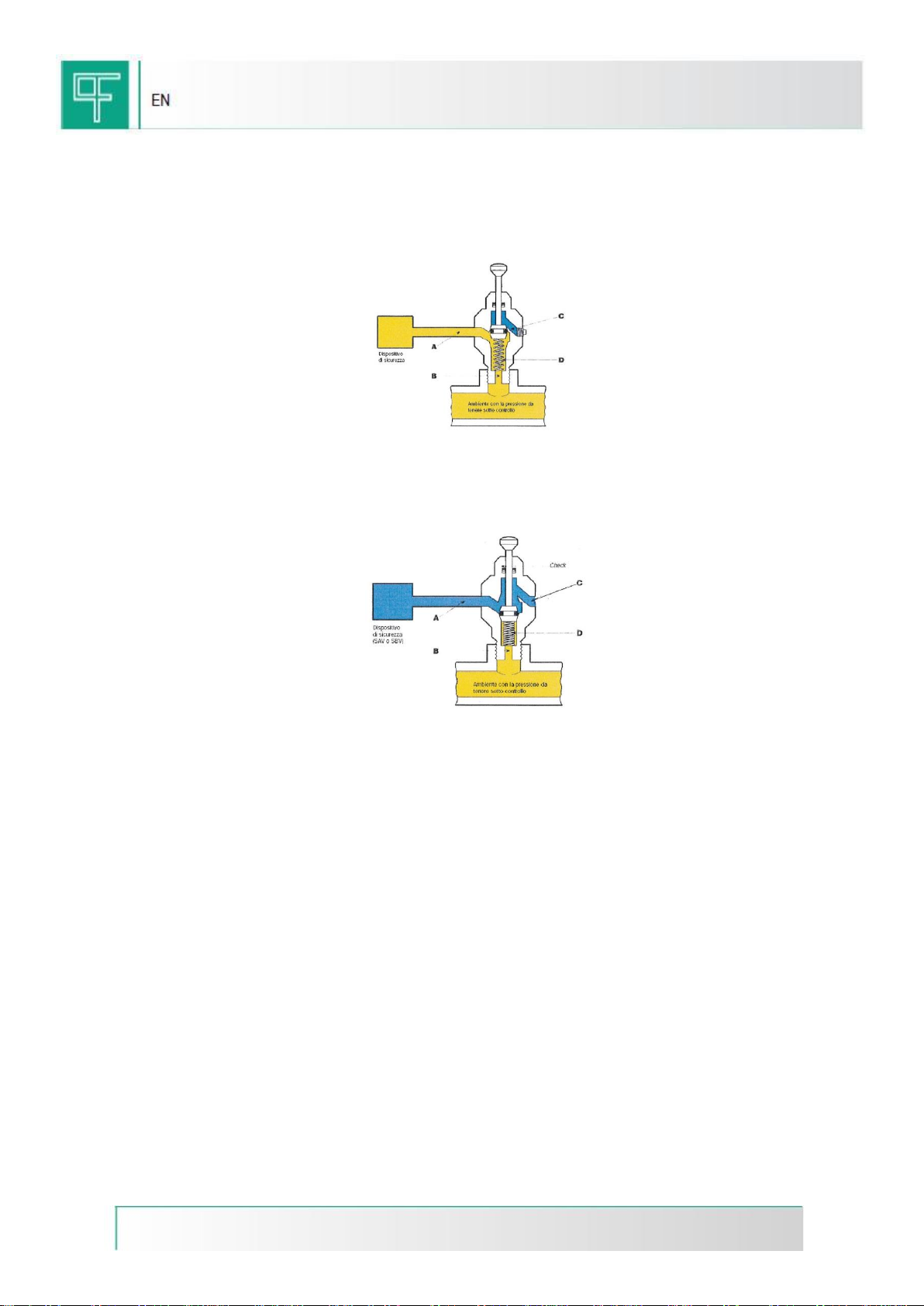

The slam-shut valve Dilock 507 / 512 / 106, as standalone equipment, is classified pursuant to the Directive 97/23/EC (PED) as:

Pressure accessory when it is forecast to trip in case of pressure increase;

Safety accessory, pursuant to paragraph 2.1.3 of Article 1 of the same Directive, when it is forecast to trip in case of both

pressure increase and decrease.