Contents

Operating Manual PNOZ s7.1

21865-EN-11 | 3

Introduction ............................................................................................................................5

Validity of documentation.......................................................................................................... 5

Using the documentation .......................................................................................................... 5

Definition of symbols................................................................................................................. 5

Safety ...................................................................................................................................... 6

Intended use ............................................................................................................................. 6

Safety regulations ..................................................................................................................... 6

Safety assessment ................................................................................................................... 6

Use of qualified personnel ........................................................................................................ 7

Warranty and liability ................................................................................................................ 7

Disposal .................................................................................................................................... 7

For your safety.......................................................................................................................... 7

Unit features ...........................................................................................................................7

Safety features ....................................................................................................................... 8

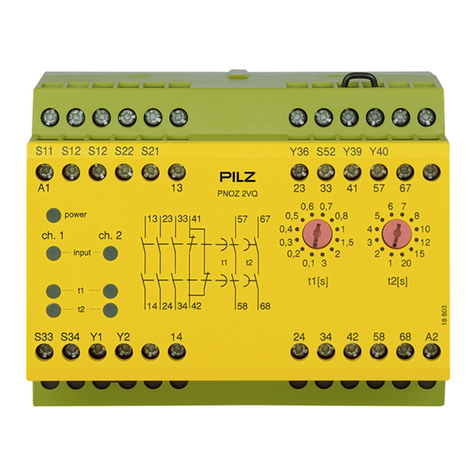

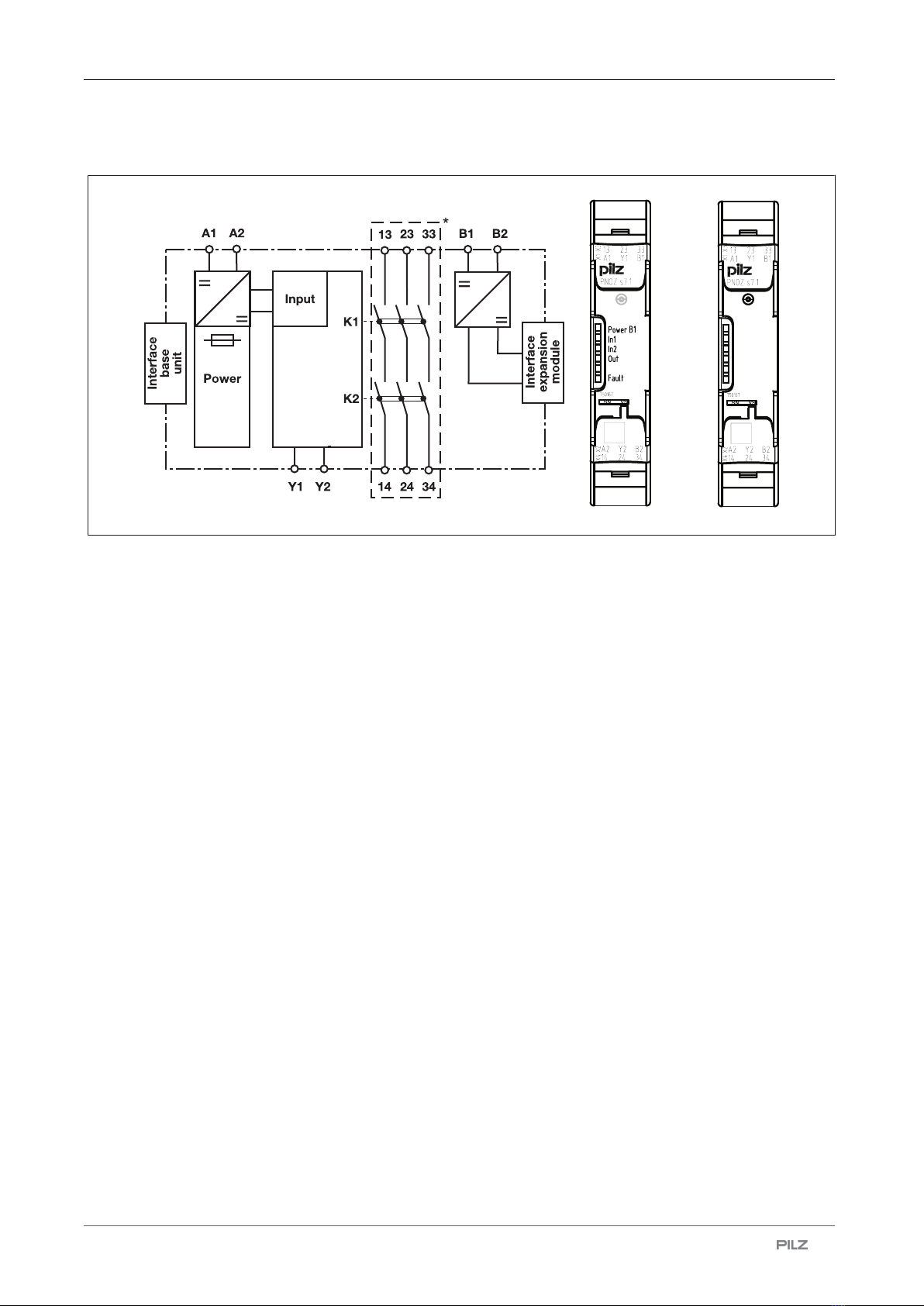

Block diagram/terminal configuration ................................................................................. 9

Function description ............................................................................................................. 9

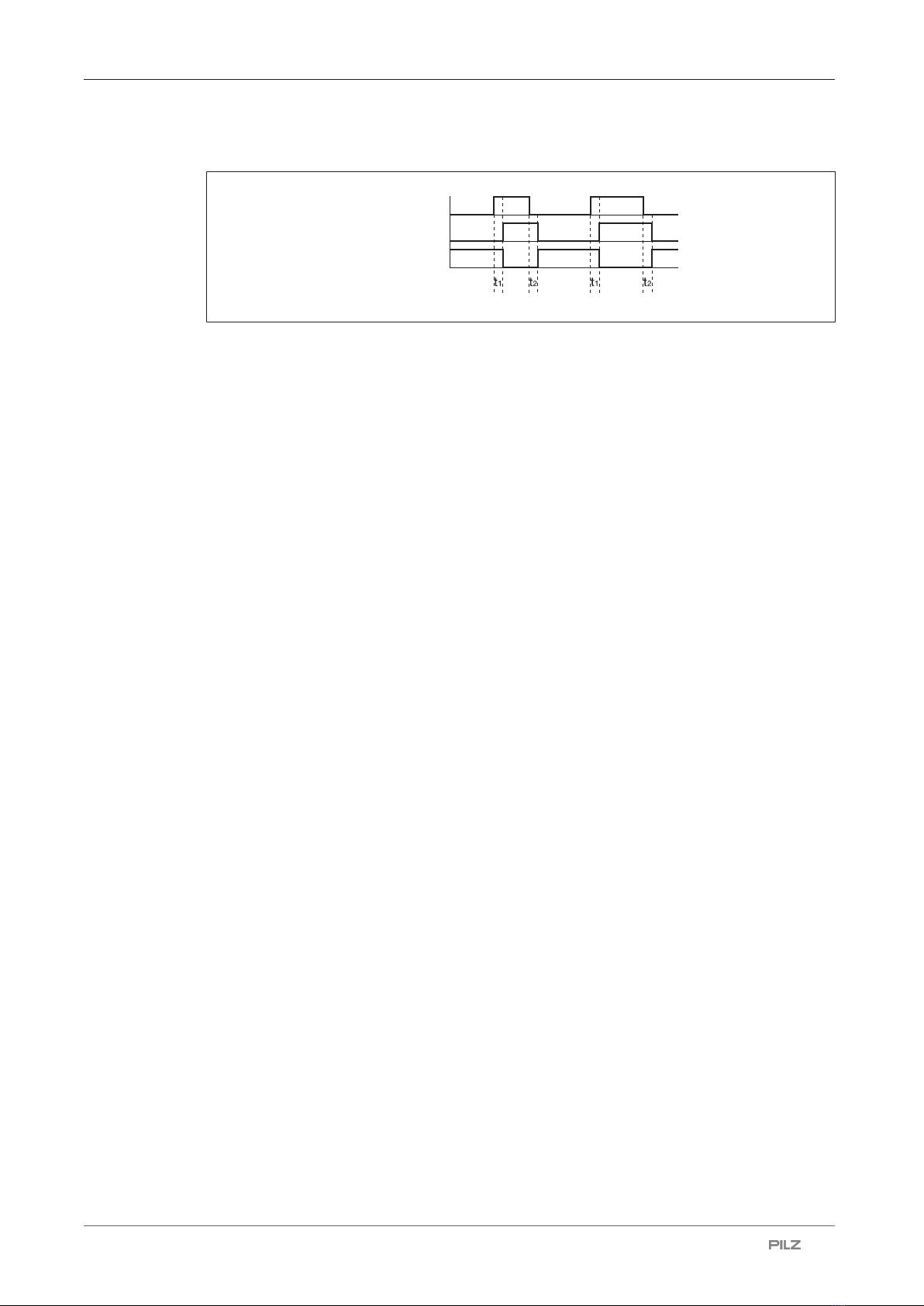

Timing diagram ......................................................................................................................... 10

Installation ..............................................................................................................................10

Wiring ......................................................................................................................................12

Preparing for operation ......................................................................................................... 13

Application examples ............................................................................................................ 14

Operation ................................................................................................................................15

Status indicators ....................................................................................................................... 16

Fault indicators ......................................................................................................................... 16

Faults - malfunctions ............................................................................................................. 16

Dimensions in mm .................................................................................................................16

Technical details ....................................................................................................................17

Safety characteristic data ......................................................................................................... 20

Classification according to ZVEI, CB24I ................................................................................... 21

Supplementary data ..............................................................................................................22

Service life graph ...................................................................................................................... 22

Permitted operating height........................................................................................................ 24