PNOZ 2VJ

Operating Manual PNOZ 2VJ

18604-EN-04 8

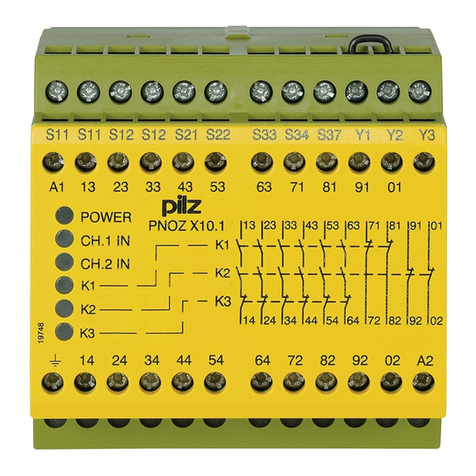

Function Description

The safety relay PNOZ 2VJ provides a safety-oriented interruption of a safety circuit. When

supply voltage is supplied the "POWER" LED is lit. The unit is ready for operation when the

feedback loop Y1-Y2, the reset circuit Y39-Y40 and the start circuit S33-S34 are closed.

}Input circuit is closed (e.g. E-STOP pushbutton not operated):

– The LEDs "CH.1 Input", "CH.1 t1", "CH.1 t2" and "CH.2 Input", "CH.2 t1", "CH.2 t2"

are lit.

– Safety contacts 13-14, 23-24, 33-34, 57-58 and 67-68 are closed, auxiliary contact

41-42 is opened. The unit is active.

}Input circuit is opened (e.g. E-STOP pushbutton operated):

– The LEDs "CH.1 Input" and "CH.2 Input" go out.

– Safety contacts 13-14, 23-24 and 33-34 are opened redundantly, auxiliary contact

41-42 is closed.

– Once the delay time t1 has elapsed, safety contact 57-58 opens.

– LEDs "CH.1 t1" and "CH.2 t1" go out.

– Once the delay time t2 has elapsed, safety contact 67-68 opens.

– The LEDs "CH.1 t2" and "CH.2 t2" go out.

The delay times t1 for safety contact 57-58 and t2 for safety contact 67-68 can be set on

the front of the unit using a screwdriver.

Reset function:

The cycle for delay times t1 and t2 can be ended prematurely by opening the reset circuit

Y39-Y40. For this purpose, one N/C contact is connected between Y39-Y40 instead of a

link.

NOTICE

If the safety requirement (e.g. E-STOP pushbutton operated) is triggered <

6 s after starting, the delay-on de-energisation of the instantaneous safety

contacts may be increased (see Technical details [ 15]).

Operating modes

}Single-channel operation: No redundancy in the input circuit, earth faults in the start

and input circuit are detected.

}Dual-channel operation without detection of shorts across contacts: Redundant input

circuit, detects PNOZ 2VJ

– earth faults in the start and input circuit,

– short circuits in the input circuit.

}Automatic start: Unit is active once the input circuit has been closed.

}Manual start: Unit is active once the input circuit and the start circuit are closed.

}Increase in the number of available contacts by connecting contact expander modules

or external contactors/relays.