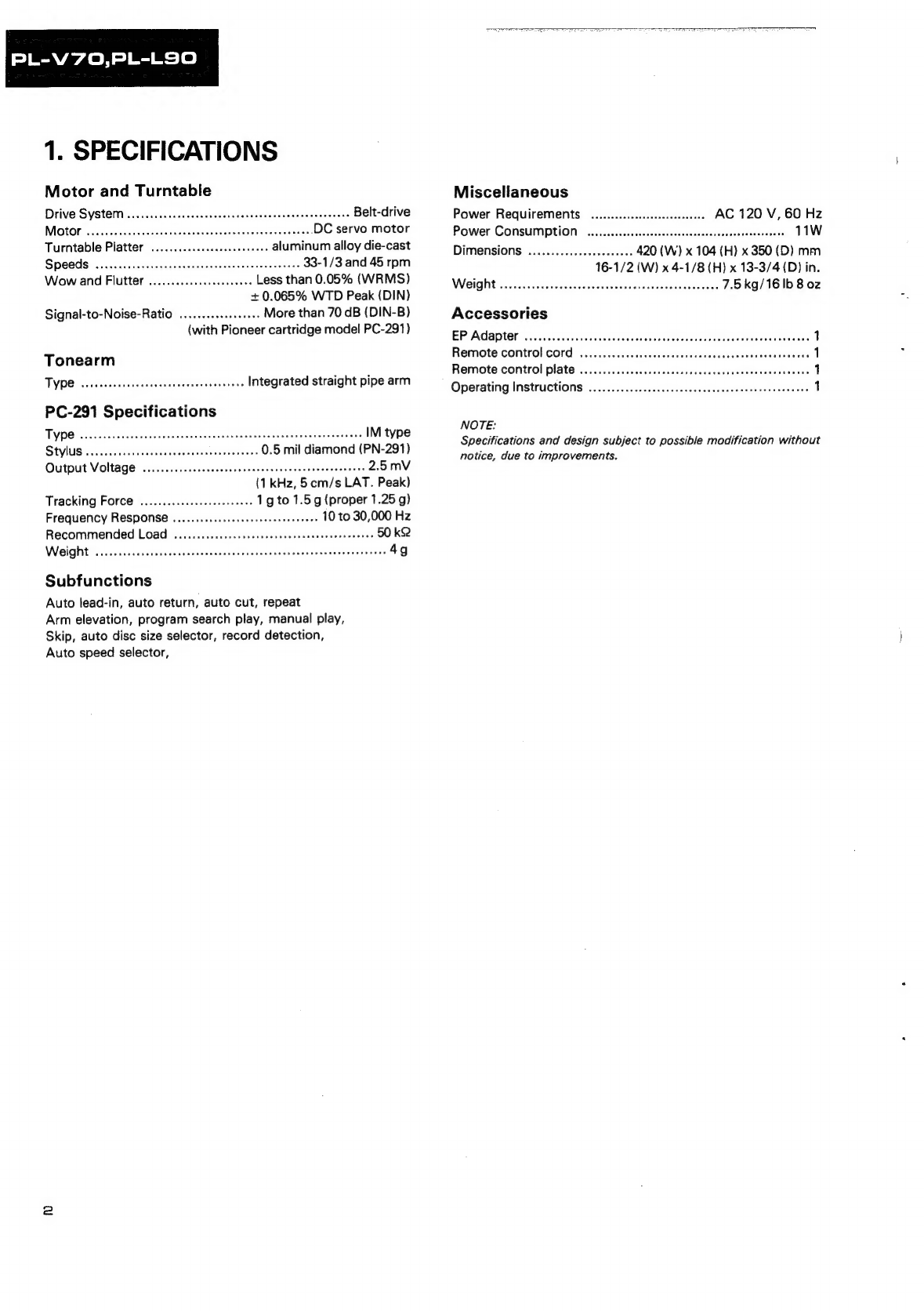

PL-V70,PL-LSO

1.

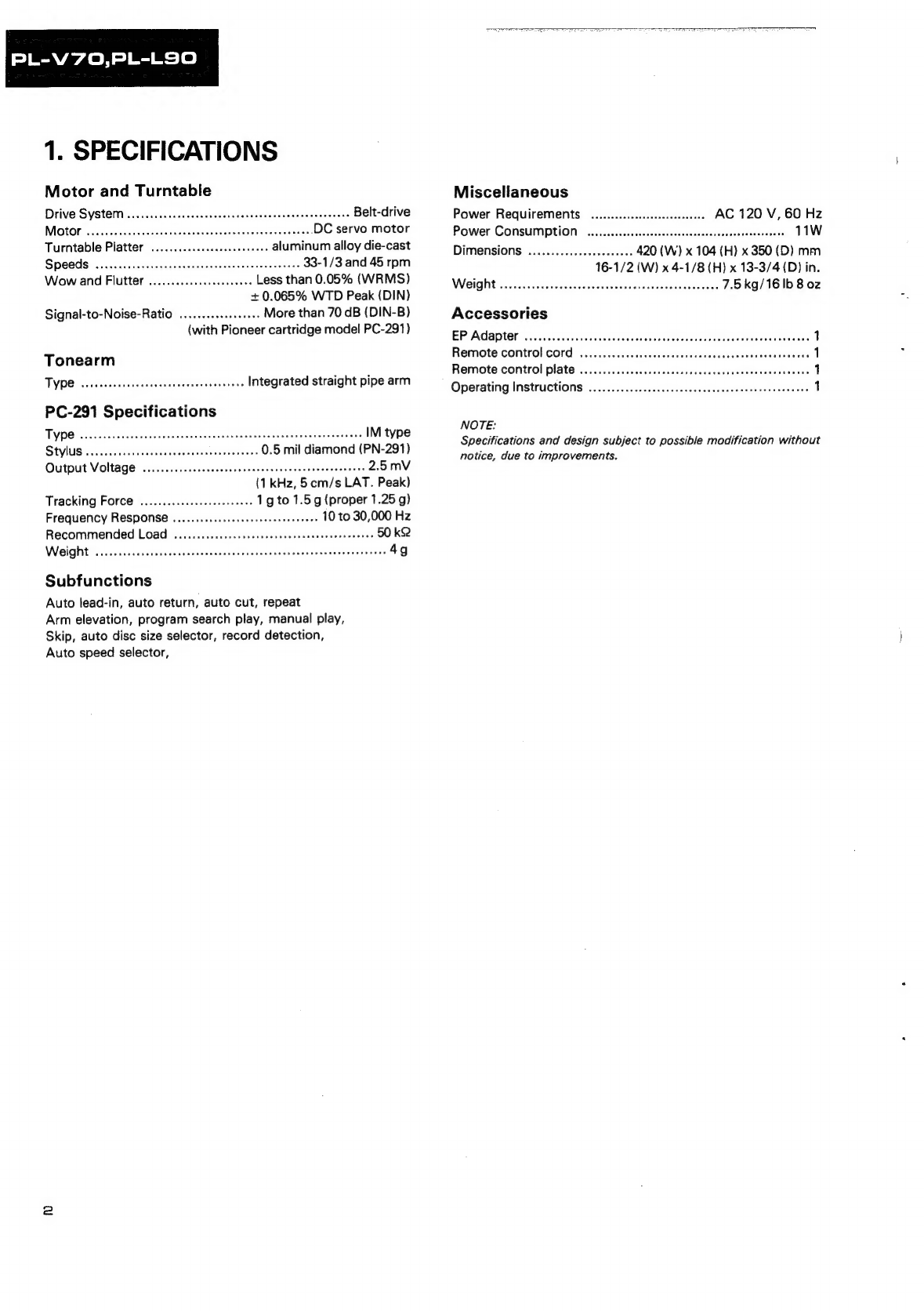

SPECIFICATIONS

Motor

and

Turntable

Drive

SYSteM

.......c.ccesceceeseeecneeseseneraeeeseererseenes

Belt-drive

MOtOP

suskeioccitdevasesssacecvasrepeees

vie

eeeresetene

DC

servo

motor

Turntable

Platter

...........:cceseseeeeeues

aluminum

alloy

die-cast

SPECS

ieee

veer

edces

dendessecisbastedidancssnes

nas

33-1/3

and

45

rpm

Wow

and

Flutter

..............0ee

eee

e

ee

Less

than

0.05%

(WRMS)

+

0.065%

WTD

Peak

(DIN)

Signal-to-Noise-Ratio

.........cccseee

More

than

70

dB

(DIN-B)

(with

Pioneer

cartridge

model

PC-291)

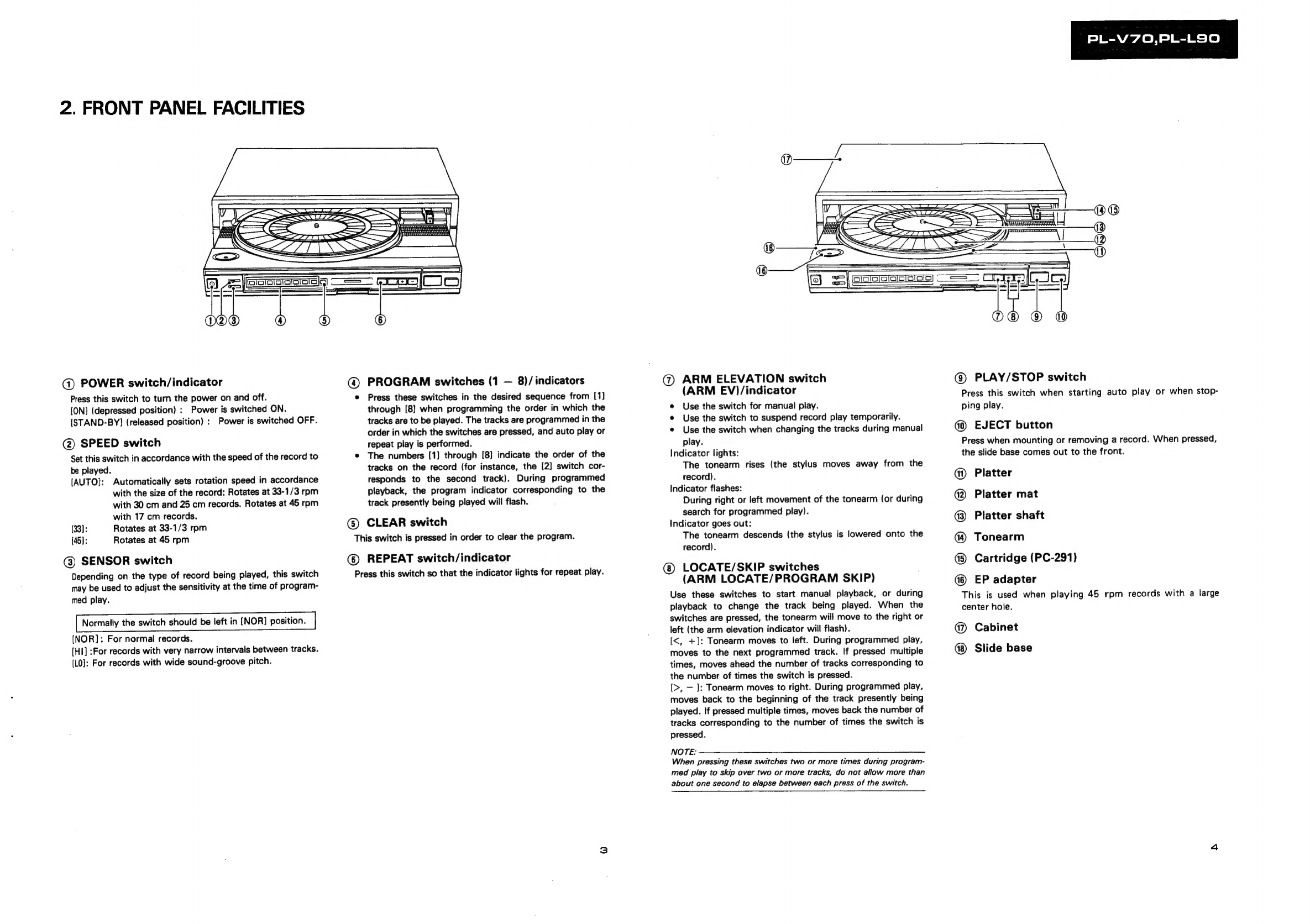

Tonearm

TY

DO)

iseiccvssannstusvssedessioisecessece

Integrated

straight

pipe

arm

TYPO

costs

ceiehscetnaladiedanceccccceasseatenpateceunvestepaoedetes

IM

type

Stylus

sc.csssacteasecvivewseheiteecsssvestes

0.5

mil

diamond

(PN-291)

Output

Voltage

........eccecceseseneeereeeneeeeeeeeeeeeeen

ene

2.5mV

(1

kHz,

5cm/s

LAT.

Peak)

Tracking

Force

........ccceeceeeeeeeee

ee

1g

to

1.5

g

(proper

1.25

g)

Frequency

RESponse

........:ccseeeeeeseeseseeeeeees

10

to

30,000

Hz

Recommended

Load

.......ccccceceseseeeeneeeneeanaeeeeeseenes

50

k&

WEIGH

.......:cccesesccecscrscnsccsccecncnceecsea

seer

rsssaseneeeeenes

4g

Subfunctions

Auto

lead-in,

auto

return,

auto

cut,

repeat

Arm

elevation,

program

search

play,

manual

play,

Skip,

auto

disc

size

selector,

record

detection,

Auto

speed

selector,

Miscellaneous

Power

Requirements

.......ccsssssesssesssesenens

AC

120

V,

60

Hz

Power

Consumption

.........ccssscesssssscereesceresseveceeeaeeserens

11W

Dimensions

............0se0eeeeees

420

(W)

x

104

(H)

x

350

(D)

mm

16-1/2

(W)

x

4-1/8

(H)

x

13-3/4

(D)

in.

Wight

223

cc.

idesseedescdades

avibanccnideddeseensaced

7.5

kg/16

lb

8

oz

Accessories

EP(Adapter’

ei

eisescosteohe

dneeecasacseutsgaacee

diac

Veadavbecewisindses

1

Remote

control

COrd

.........ccccsceceeescuteceseeseecneeeneseenceaees

1

Remote

control

plate

...........cccscscececceeeceneeeeeeeseeneeertenaes

1

Operating

INStructions

...........cccccsecececeneseeceeeeeeeenneseenee

1

NOTE:

Specifications

and

design

subject

to

possible

modification

without

notice,

due

to

improvements.